Complete Guide to Heat Shrink & Electrical Tape

Heat Shrink & Electrical Tape: what is it?

Heat Shrink Tubing and Electrical Tape provide reliable insulation, moisture protection and colour coding for wiring in industrial, automotive and electrical installations.

What is Heat Shrink?

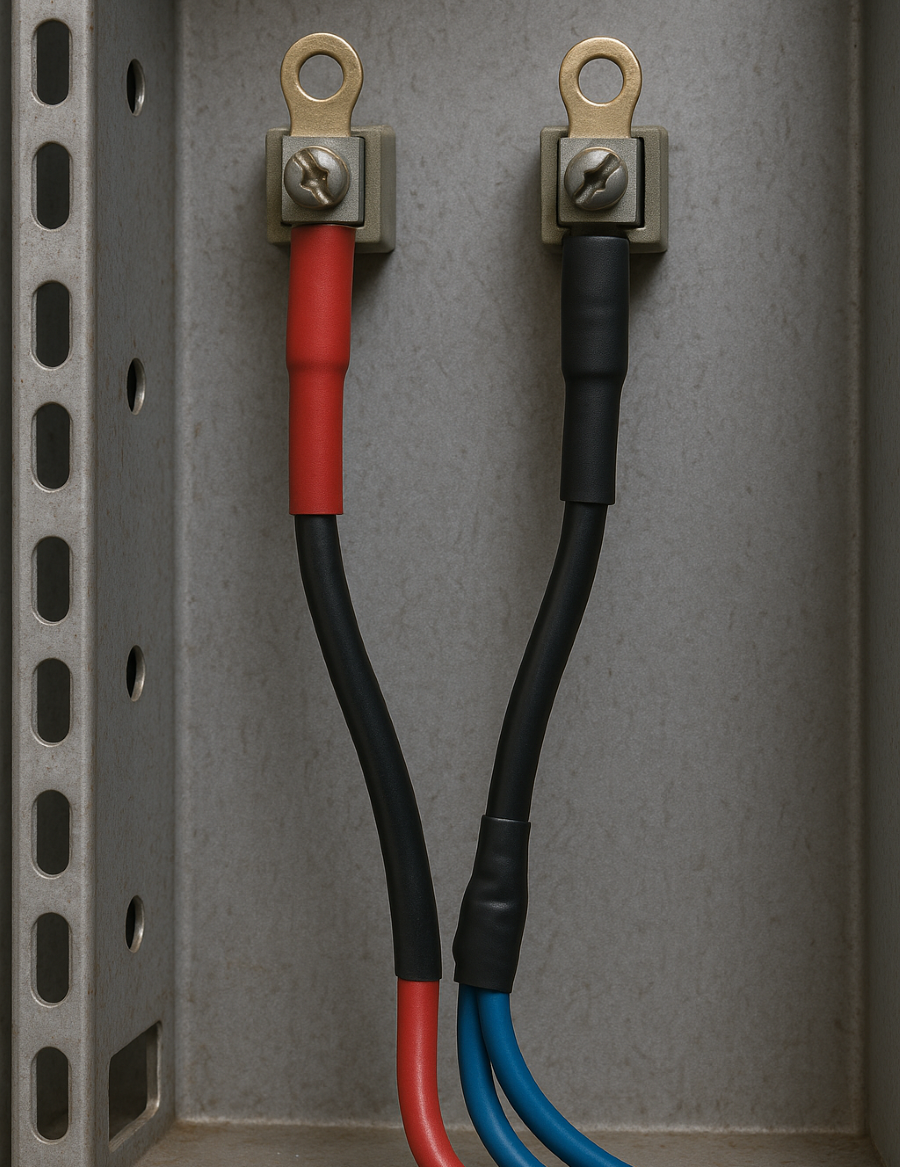

Heat Shrink is a shrinkable plastic sleeve—typically made of polyolefin, PVC or fluoropolymers—that contracts tightly around wires when heated. It offers excellent dielectric insulation, mechanical protection, and seals against dust and moisture. Shrink ratios like 2:1 or 3:1 define its tightness after heating, making it ideal for repairing or bundling wires and terminating cable ends.

What is PVC Electrical Tape?

Electrical insulation tape is a flexible, adhesive PVC tape conforming to BS EN 60454‑3‑1. With dielectric strength up to ~40 kV/mm and temperature resistance from –18 °C to +105 °C, it delivers flame-retardant, moisture-resistant protection. Common uses include insulating wire joints, bundling cables, color coding, and general repairs.

Heat Shrink vs Electrical Tape: what's the difference?

Heat shrink provides a more reliable, long-lasting solution for permanent wiring, while electrical tape is ideal for quick installations or temporary fixes. Over time, tape’s adhesive may degrade, unlike the constant protection offered by heat shrink.

| Feature | Heat Shrink Tubing | PVC Electrical Tape |

|---|---|---|

| Material | Polyolefin, PVC, or fluoropolymer tubing | Flexible PVC with pressure-sensitive adhesive |

| Application Method | Slid over the wire, then shrunk with heat | Wrapped directly around the wire manually |

| Insulation Quality | Excellent – creates tight, uniform coverage | Good – may leave small gaps or loosen over time |

| Sealing Ability | High – especially with adhesive-lined versions | Moderate – not waterproof; adhesive may degrade |

| Mechanical Protection | Strong – resists abrasion and strain | Light – mainly protects from surface wear |

| Durability | Long-term/permanent installations | Short- to medium-term use, often temporary |

| Ease of Use | Requires heat gun or lighter | Tool-free, fast application |

| Flexibility | Rigid after shrinking | Highly flexible before and after application |

| Typical Uses | Permanent wire insulation, strain relief, moisture sealing | Bundling wires, marking, quick fixes, temporary insulation |

| Environment Suitability | Indoor/outdoor, industrial, marine, automotive | Indoor, low-moisture environment |

Applications

| Application | Best Choice | Why it’s Suitable |

|---|---|---|

| Wire joint sealing | Heat Shrink | Tight seal, abrasion & moisture protection |

| Bundling and identifying wires | Electrical tape | Fast application, visible color options |

| Cable strain relief | Heat Shrink | Adds mechanical strength and support |

| Temporary repair | Electrical tape | Easy removal, flexible rework |

| Environmental sealing | Heat Shrink (adhesive‑lined) | Waterproof and dust-tight sealing |

Installation Tips

| Heat Shrink | Electrical Tape |

|

|

Benefits of Heat Shrink

Moisture & Environmental Protection

Mechanical Strength & Abrasion Resistance

Superior Electrical Insulation

Safety and Compliance

Benefits of PVC Electrical Tape

Flexible and Easy to Install

Flame Retardent & UV Resistant

Colour Coding & Identification

Wide Temperature & Environmental Range

Heat Shrink & PVC Cable Sleeving Colour Classification

| Colour | Function |

| Black | To be used for a three phase line wire. |

| Clear | To be used for general purpose protection- allowing for visual inspection. |

| White | To be used for general purpose protection. |

| Red | To be used for positive wires or hot connections. |

| Blue | To be used for a Neutral wire. |

| Yellow | To be used for general purpose protection. |

| Green | To be used for general purpose protection. |

| Green/Yellow | To be used for a protective earth (PE) or ground wire. |

| Brown | To be used for a single and three phase line (L1) wire. |

| Grey | To be used for general purpose protection. |

| Pink | To be used for Functional Earth wires according to clause 514.4 & Table 51 |

Wiring Systems

Single Phase Wiring System

This is the most commonly used type of Wiring System and is predominantly used in domestic settings such as Households due to the low demand of power. It can supply a voltage of around 240V and consists of three wires: Earth, Live and Neutral.

Three Phase Wiring System

This System is commonly used in industrial settings such as factories where it can supply a voltage of around 415V. It consists of either five wires: three lives, an earth and a neutral, or four wires depending on whether a neutral wire is present: three lives and an earth.

Functional Earth VS Protective Earth Conductors

Functional Earth

- No shock protection from a hazardous voltage

- Used within electrical systems to provide a specific function such as interference suppression

- Must be insulated with Pink Cable Sleeving

- Particularly important within fire detection and fire alarm systems due to extra-low voltage circuits (ELV) being present

Protective Earth

- Shock protection from a hazardous voltage

- Used for safety purposes

- Must be insulated with Green & Yellow Cable Sleeving

- Main role is to provide a path for a fault current to be directed to earth in the safest way

Explore Related Products

If you require alternative materials or a wider selection of Cable Management products, explore our related categories:

Rubber Grommets

Our Rubebr Grommets are used to seal pff, thread through and protect cables within wiring outlets.

Cloth Tape (Gaffer Tape)

Our Cloth Tape is ideal for use within photography, film and radio applications due to its high melting point.

Spiral Cable Wrap

Our Spiral Cable Wrap is ideal for bundling and protecting cables. They are easy to install and remove; allowing for cable breakouts at any point.

Frequently Asked Questions

Leave a comment