Customer Case Study: Temperature Controlled Packaging

THE PROJECT

Our customer came to us in 2022 with a unique problem; they found that their vacuum insulation panels which were filled with various biothermal liquids, were leaking due to unsecure caps which were not robust enough for the intended application.

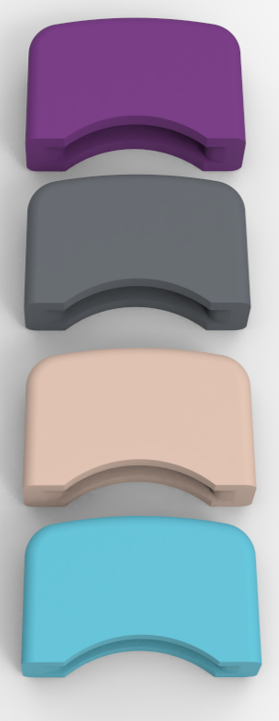

Their brief was simple and to the point; they needed secure and reliable caps in a range of colours so that the insulation panels could be colour coded. We informed the customer that this was going to be a custom project that could take some time to perfect, which they gratefully acknowledged and asked us to proceed with.

How did we support our customer with this custom project?

A unique problem requires a unique resolution, which is why we explored 3 different cap designs, created 8 versions of the chosen design with the use of a 3D printer and created a prototype of the tool needed to make them.

Our Business Development lead, Dan Blewett, and our Technical and New Product Specialist, Conor Rouillier, were at the forefront of this project over the course of 2 years.

Step 1) Inbound phone call recieved By Dan Blewett where the customer explained that their existing cap was poorly fitting

Step 2) Meeting arranged with the customer to better understand their requirements

Step 3) Customer sent over their original cap to the technical office in Bournemouth for the technical team to review

Step 4) Many calls took place in order to keep the customer up to date with the project and discuss options

Step 5) Finally, after many designs and prototypes, Dan and Conor made an in-person visit to the customer to reveal the final product. This part is now in full production, with over 1 million parts ordered!

Q & A's

Here we will explore the sales experience from the point of view of Dan and Conor who headed up the project

Q1 - Which aspect of this project did you find most enjoyable?

'I most enjoyed prototyping the design!' - Conor

'Being an external part of their purchasing team!' - Dan

Q2 - Which aspect of the project did you find most challenging?

'Choosing a suitable material that was compatible with the low temperatures involved.' - Conor

'Finding a part that would fit multiple crimps but still provide the required level of security.' - Dan

Can we help you with a standard or custom project?

Please get in touch if you would like to speak with a member of our Sales team regarding standard or custom parts.

CONTACT SALES

Leave a comment