PCB Assembly Components for Reliable Manufacturing

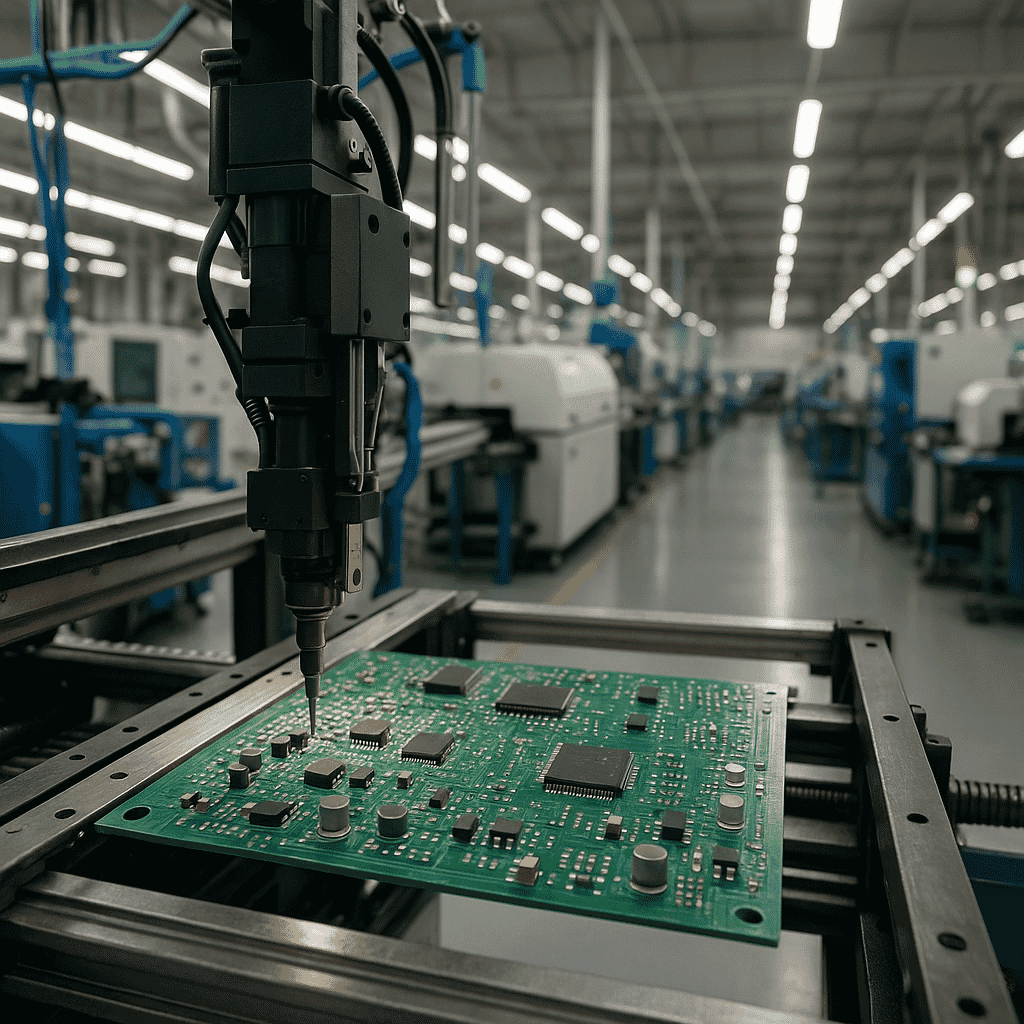

The PCB assembly industry requires exceptional precision and reliability, where component failures can compromise entire production batches and lead to costly field returns. Electronics manufacturers need dependable fastening solutions, spacers, and cable management components that ensure consistent assembly quality while meeting stringent industry standards.

UK electronics manufacturers consistently select our precision assembly components because they deliver exceptional reliability in challenging production environments, spanning automotive ECUs through to high-volume consumer electronics manufacturing.

From maintaining critical board-to-board spacing with precision hex spacers to securing delicate components using thread-forming plastic screws, our product range ensures reliable cable management through professional snap rivets and heat shrink solutions—all engineered for the demanding standards of modern PCB assembly operations.

Electronics professionals utilise proper component selection and advanced cable management techniques to achieve consistent assembly quality whilst minimising costly field failures. Learn more about PCB assembly fundamentals.

Essential Components for PCB Assembly

Discover our most trusted assembly components, specifically selected for reliability in electronic manufacturing applications.

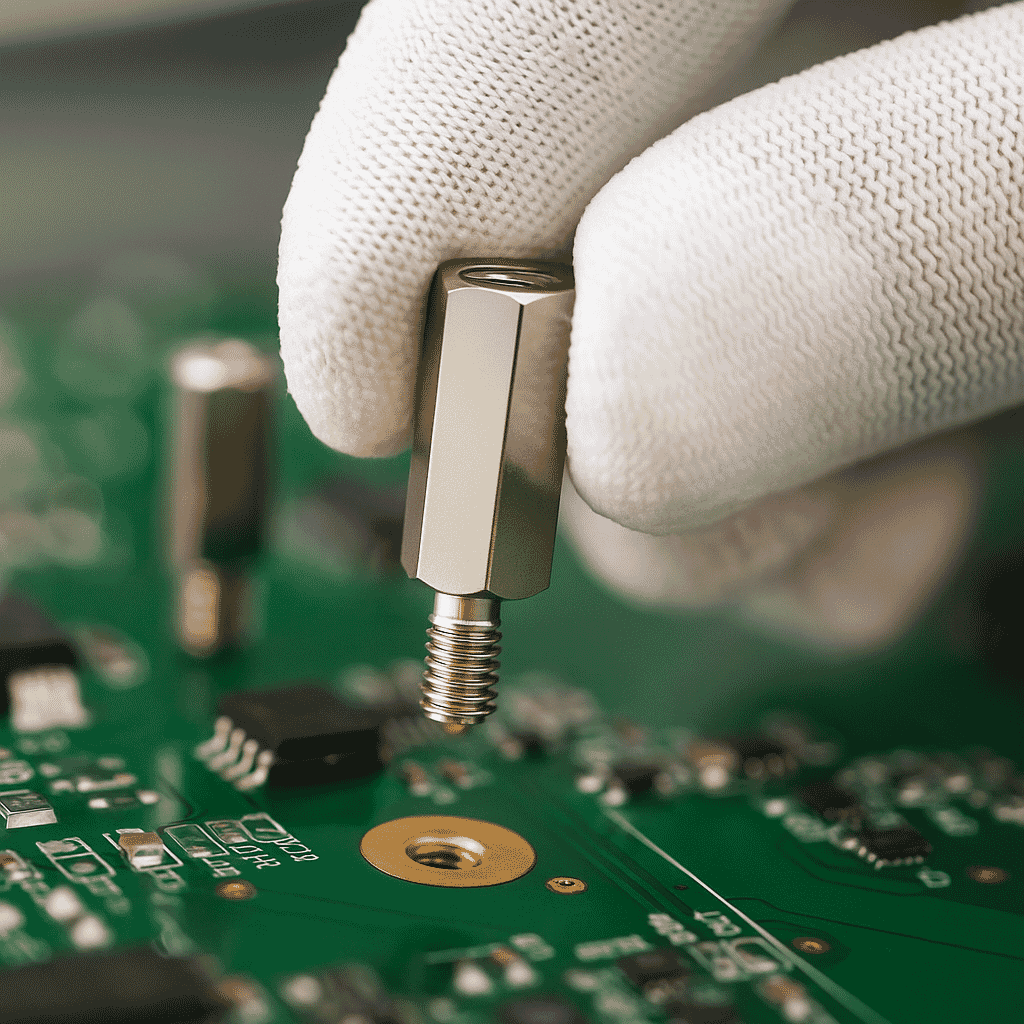

Hex Spacers

Precision-manufactured nylon and metal hex spacers for maintaining accurate board-to-board spacing and component clearances. Essential for multi-layer assemblies and enclosure mounting.

- Various lengths from 3mm to 50mm

- Male/female and female/female options

- Available in nylon and brass materials

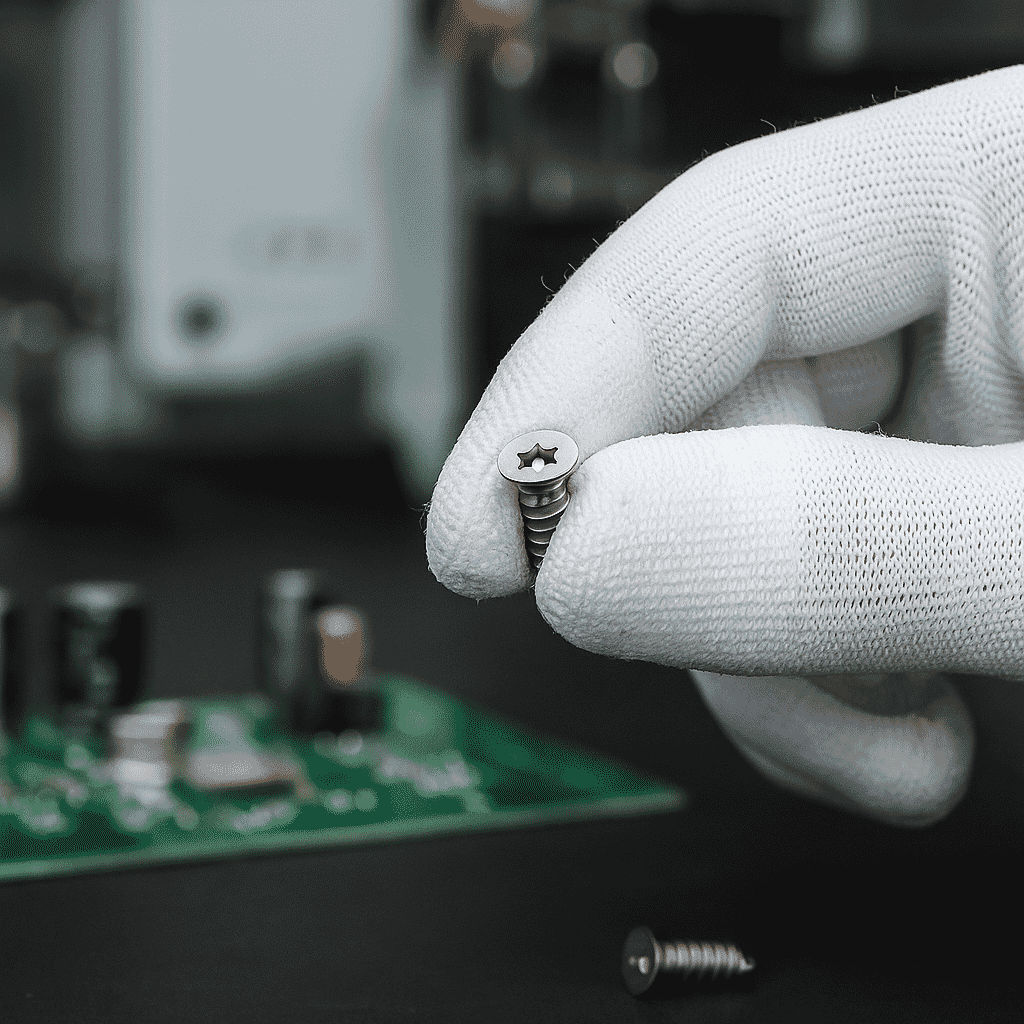

Screws for Plastics

Specialised thread-forming screws designed for secure fastening into plastic enclosures and housings without cracking or stress damage. Ideal for electronics assembly applications.

- Thread-forming design prevents cracking

- Various head styles and lengths

- Corrosion-resistant coatings available

Snap Rivets

Quick-install fastening solutions for securing cable assemblies, PCBs, and components within enclosures. Provides reliable retention with easy installation and removal.

- No-tool installation and removal

- Multiple panel thickness options

- Reusable design for maintenance access

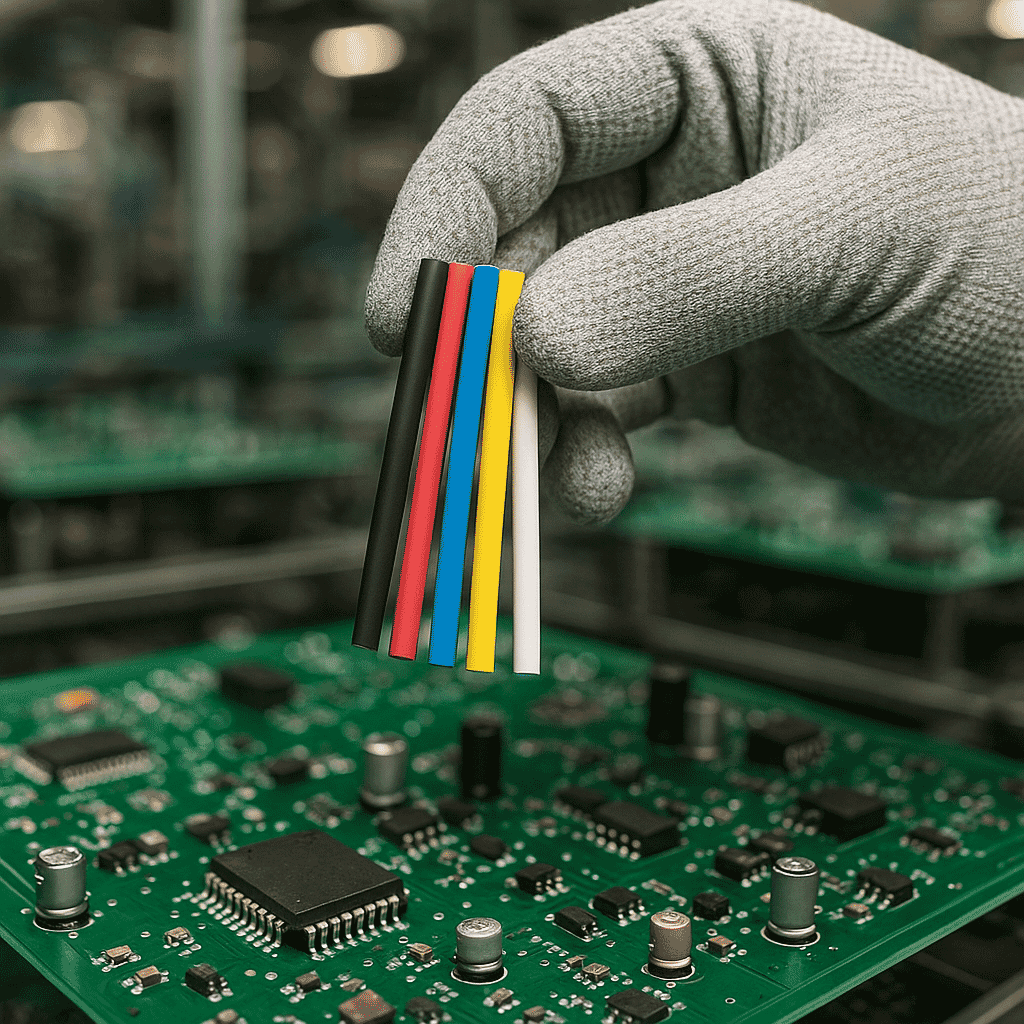

Heat Shrink Tubing

Professional-grade heat shrink tubing for wire splicing, connection protection, and strain relief in PCB assemblies. Available in various shrink ratios and operating temperatures.

- 2:1 and 3:1 shrink ratios available

- Operating temperatures up to 125°C

- Multiple colors for wire identification

PCB Assembly Components - Frequently Asked Questions

What are the minimum component spacing requirements for reliable assembly?

Component spacing requirements vary by assembly method and component type. Surface mount components typically require 0.25mm minimum spacing for Class 1/2 designs, whilst high-density assemblies may use 0.15mm clearances. Proper spacing prevents solder bridging, allows for rework access, and accommodates manufacturing tolerances. Hex spacers ensure consistent board-to-board distances, whilst plastic screws provide secure fastening without stress-cracking in confined spaces.

How can I prevent thermal issues and component overheating during assembly?

Thermal management requires strategic component placement to avoid hotspots, adequate spacing for airflow, and proper heat dissipation paths. High-power components should be positioned with sufficient clearance, and heat-sensitive parts placed away from heat sources. Effective cable management using snap rivets and organised routing with heat shrink tubing helps maintain airflow whilst protecting connections from thermal stress.

What's the best way to manage cables and wiring in PCB assemblies?

Professional cable management prevents signal interference, mechanical damage, and assembly complications. Snap rivets provide quick, tool-free cable securing to panels and enclosures, whilst heat shrink tubing offers strain relief and environmental protection for wire splices. Proper cable routing maintains required clearances from sensitive circuits and allows adequate access for testing and maintenance.

Why do plastic enclosures crack around screw fasteners?

Standard machine screws can cause stress concentration and cracking in plastic materials due to their cutting action. Thread-forming screws specifically designed for plastics displace rather than cut material, creating secure fastenings without generating stress points that lead to failure. Proper pilot hole sizing and screw selection prevents costly enclosure damage during assembly and field service.

How do I calculate correct standoff lengths for multi-board assemblies?

Standoff length calculations must account for PCB thickness, component heights, required clearances, and thermal expansion. Measure the total stack-up including all boards and components, then add 1-2mm for manufacturing tolerances and thermal growth. Hex spacers in various lengths provide precise spacing control, whilst their male/female or female/female configurations allow flexible assembly architectures for complex multi-level designs.

Partner with Assembly Specialists

We collaborate with electronics manufacturers to solve complex assembly challenges. From precision hex spacers meeting critical spacing requirements to specialised cable management solutions for harsh environments, our technical team develops components that directly enhance your production efficiency and product reliability.

Explore Our Components

Leave a comment