Professional Edging Strip Solutions

Your Complete Guide to EPDM Rubber, PVC and Reinforced Edge Trims for Automotive, Solar, Motorhome and Industrial Applications

Introduction to Edging Strips

Edging strips are essential components for protecting and finishing sharp exposed edges across various industries. At Vital Parts, we offer a comprehensive range of rubber edging protection solutions designed to meet the diverse application needs of our customers across the UK.

From automotive and construction to marine and solar farms, our EPDM and PVC edging solutions deliver exceptional durability, weather resistance and professional finishing that UK industries trust.

Our Comprehensive Edging Strip Range

Vital Parts supplies four main categories of edging strips, each engineered for specific applications and performance requirements. Whether you need standard rubber edge trims, convenient self-adhesive options, heavy-duty reinforced strips, or specialized door seals, we have the solution for your needs.

Our extensive selection represents one of the UK's largest ranges of edging solutions, carefully curated to meet the exacting demands of professional installers, manufacturers and industries across the country. Each product category has been developed through years of experience working with customers to understand their unique edge protection challenges.

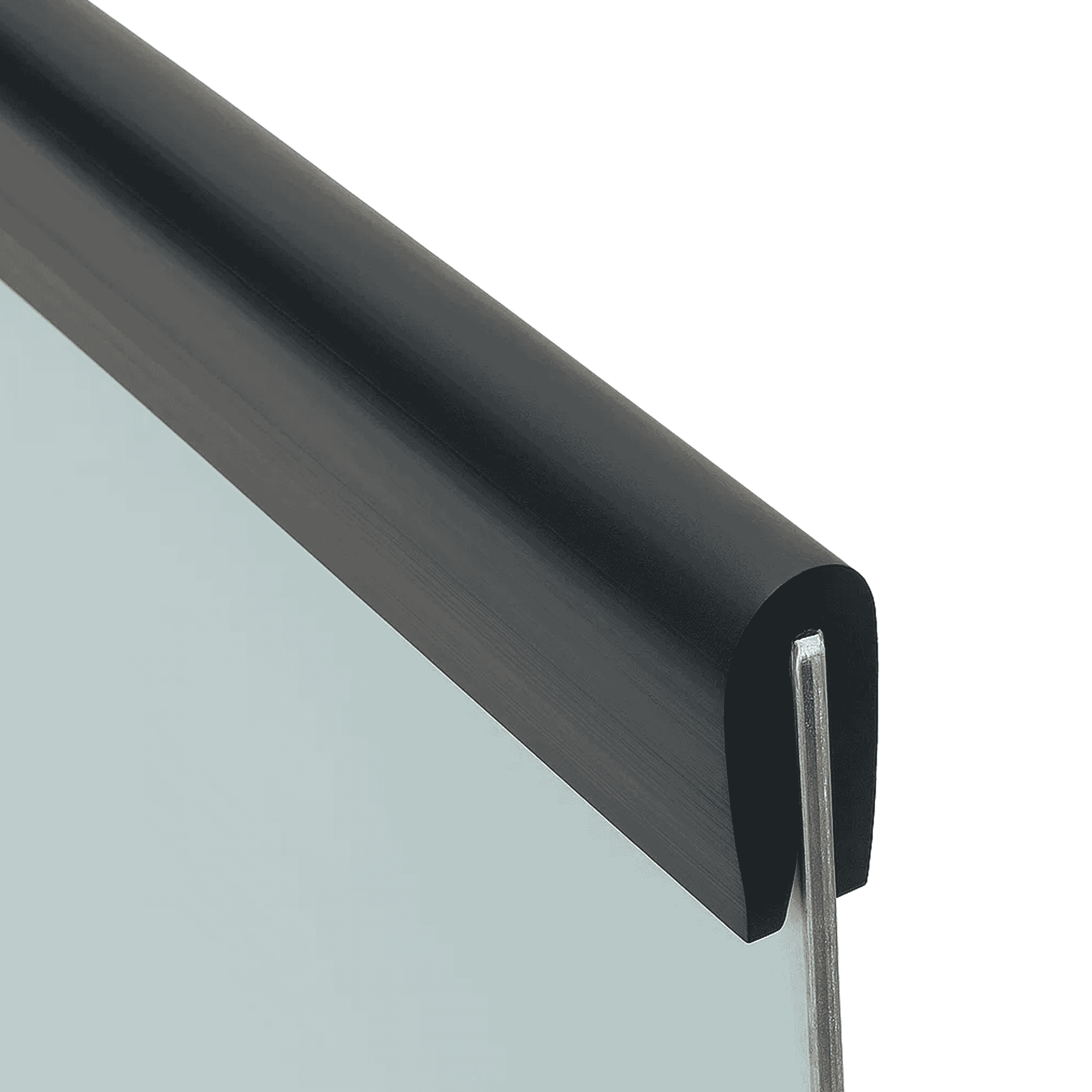

Rubber Edge Trims

Our premium-grade EPDM rubber edge trims represent the gold standard in edge protection. Manufactured from carefully selected EPDM compounds, these trims offer exceptional durability and weather resistance that outperforms standard alternatives.

- UV, ozone & weather resistant EPDM

- Temperature range: -40°C to +120°C

- Multiple profile options (Square, U, O, A-channel)

- Easy push-fit installation without tools

- Maintains elasticity across extreme conditions

- Suitable for outdoor and marine environments

Self-Adhesive Edging Strips

When speed and convenience are paramount, our self-adhesive edging strips deliver unmatched installation efficiency. Featuring pre-applied, high-strength adhesive backing, these strips eliminate the need for additional fixings, tools, or mechanical fasteners.

- Strong, permanent adhesive backing included

- No drilling, screws, or mechanical fixing required

- Perfect for motorhome and caravan panels

- Clean, professional aesthetic finish

- Quick installation saves labor time

- Ideal for interior and protected applications

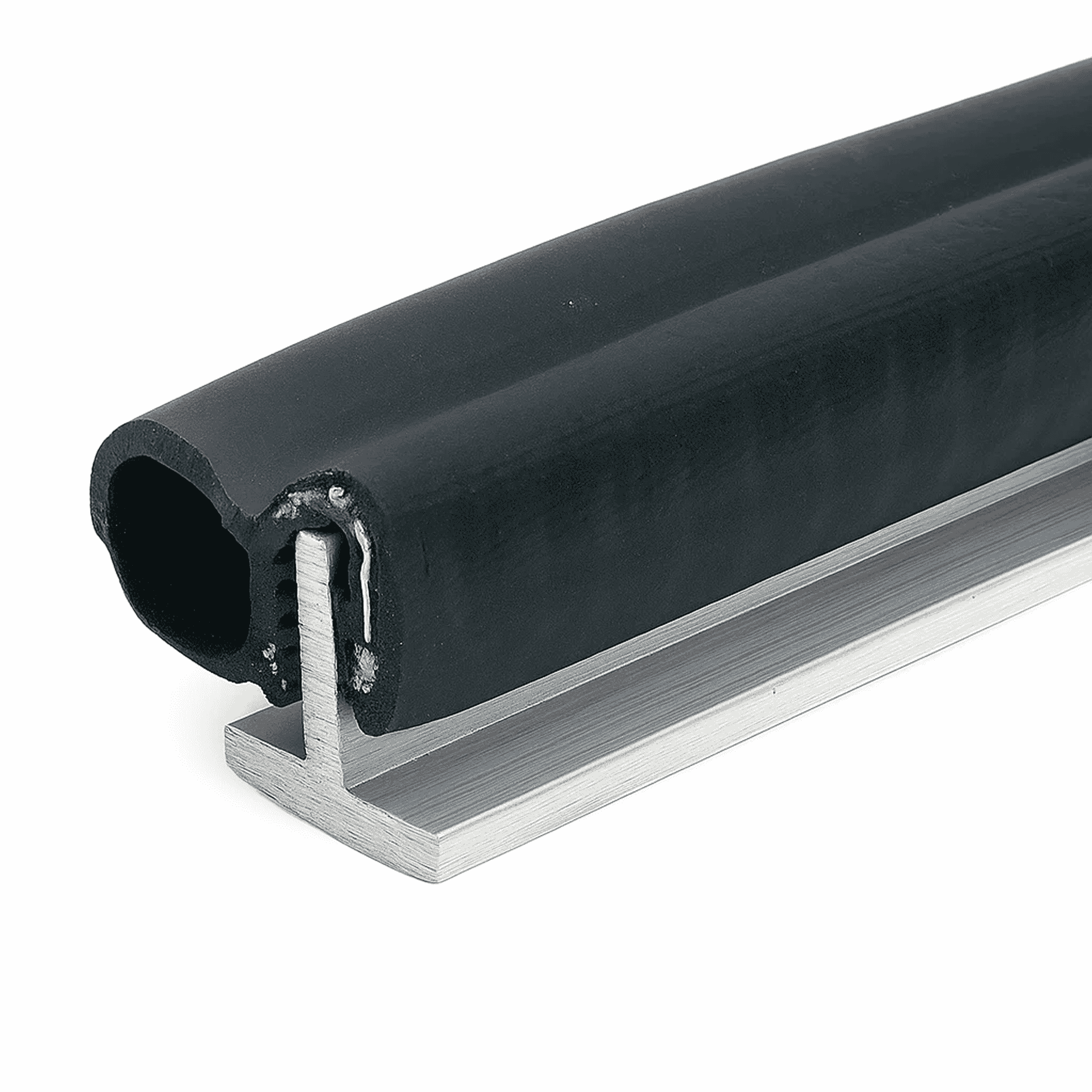

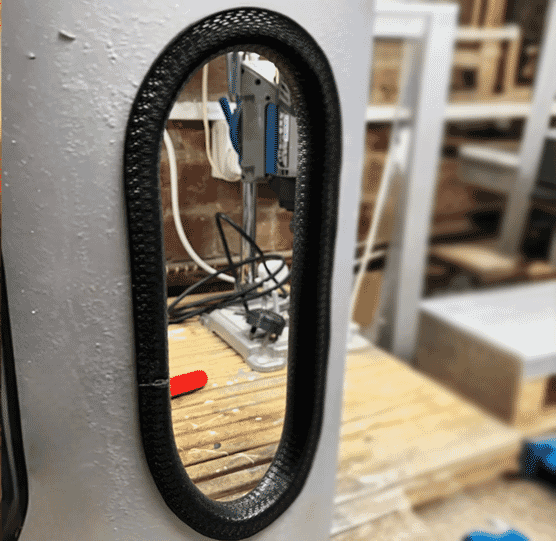

Reinforced Edge Trim

For demanding industrial environments where standard edging simply won't suffice, our reinforced edge trim delivers exceptional strength and durability. Featuring integrated metal rib reinforcement running throughout the entire length, these heavy-duty strips withstand the rigors of high-traffic industrial settings.

- Metal rib reinforcement for superior strength

- Ideal for high-impact industrial environments

- EPDM or PVC construction options available

- Protects heavy machinery and equipment edges

- Custom sizing and lengths upon request

- One of the UK's largest selections available

Rubber Door Trims

Our specialized rubber door trims serve the dual purpose of edge protection and environmental sealing. Engineered specifically for door applications across automotive, marine and industrial sectors, these trims create effective barriers against water ingress, drafts and noise transmission.

- Vehicle and motorhome door sealing

- Prevents water ingress and eliminates drafts

- Reduces noise transmission effectively

- Suitable for marine hatch applications

- Industrial cabinet and enclosure doors

- Durable, long-lasting performance

Can't Find Exactly What You Need? Vital Parts offers custom sizing, specialized profiles and bulk length options for all our edging strip categories. Our technical team can work with you to develop bespoke solutions for unique applications. Contact us on 01233 713 581 to discuss your requirements.

Edging Strip Custom Lengths

← Scroll horizontally to view the complete image →

Why Choose Edging Strips?

- Enhanced Safety: Cover sharp or unfinished edges, minimizing injury risk and ensuring compliance with workplace health and safety laws

- Easy Installation: Quick and easy to fit onto edges without specialized tools or glues

- Weather Resistance: EPDM exhibits strong resistance to UV, ozone, saline and weather conditions

- Aesthetic Appeal: Adds a clean, professional finish to any application

- Durability: Long-term performance reduces the need for frequent replacements

- Versatility: Available in multiple profiles for different edge protection needs

Industry Applications

Our edging strips deliver reliable protection across diverse UK industries. From cutting-edge renewable energy installations to traditional manufacturing sectors, Vital Parts edging solutions play critical roles in enhancing safety, extending equipment life and ensuring regulatory compliance.

Automotive Manufacturing & Repair

The automotive sector demands edging solutions that withstand constant environmental exposure while maintaining aesthetic appeal. Our EPDM rubber edge trims excel in sealing and protecting vehicle doors, windows, trunk edges and body panels against weather, vibration and impact damage.

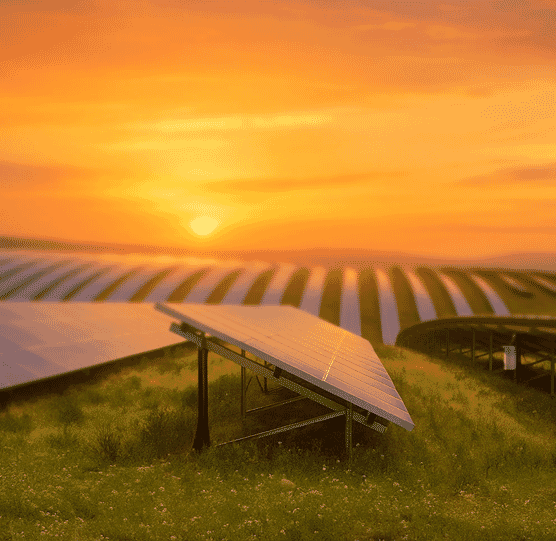

Solar Farms & Renewable Energy

EPDM's exceptional UV resistance makes our edge trims an ideal choice for protecting solar panel frameworks. Solar installations face continuous UV exposure and temperature changes. Our edging strips prevent environmental degradation of exposed metalwork while supporting the UK's growing renewable energy infrastructure.

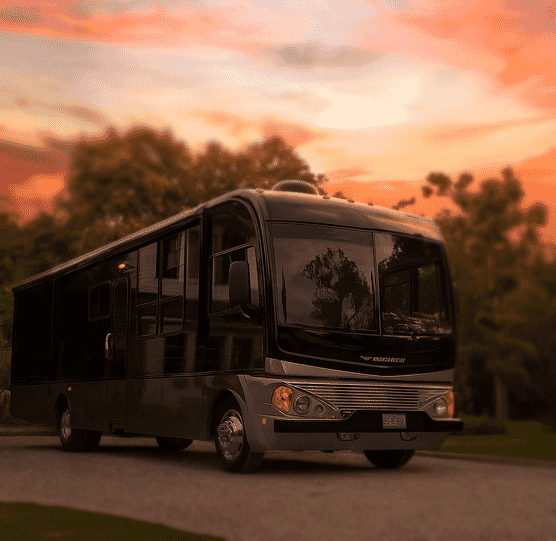

Motorhomes, Caravans & RV Manufacturing

The leisure vehicle industry presents unique edge protection challenges combining aesthetic requirements with rigorous weatherproofing demands. Our self-adhesive edging strips prove particularly valuable in motorhome construction, enabling quick, clean installations in tight interior spaces.

Construction & Building Services

Construction projects of all scales utilize edging strips to safeguard sharp edges on metal panels, glass installations and other building materials. Commercial construction projects must comply with stringent health and safety regulations regarding exposed edges and potential injury hazards.

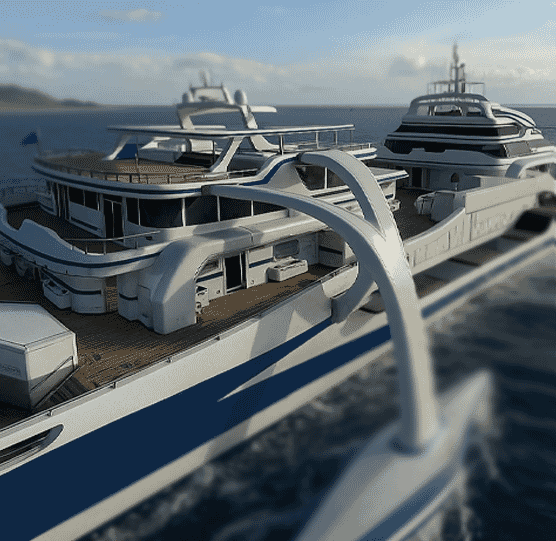

Marine & Boatbuilding

Marine environments represent some of the most challenging conditions for edging materials. EPDM's inherent resistance to both saltwater and UV exposure makes our edge trims particularly suitable for protecting edges on boats, marine equipment and waterfront structures.

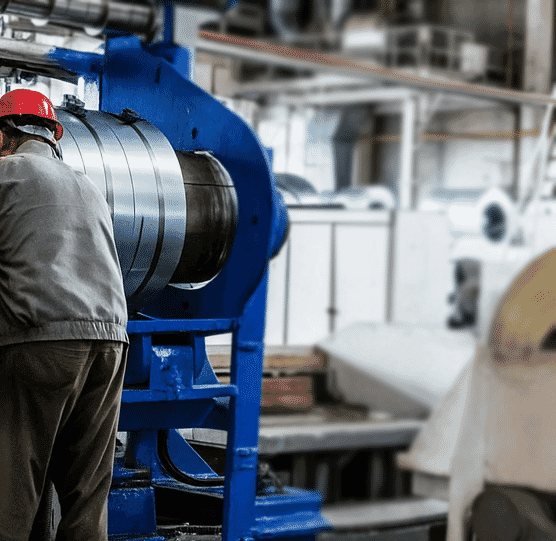

Industrial Manufacturing

Industrial environments subject edging materials to demanding conditions including mechanical stress, impact, chemical exposure and temperature variations. Our reinforced edge trim options with metal rib reinforcement deliver the superior strength required for high-traffic industrial settings.

Understanding EPDM & PVC Materials

What is EPDM Rubber?

EPDM (Ethylene Propylene Diene Monomer) rubber is a synthetic rubber that provides exceptional durability, resistance and flexibility. At Vital Parts, we're careful to supply only premium-grade EPDM rubber to ensure the durability and performance of our products.

Did You Know? Not all EPDM is created equally! Premium-grade EPDM offers significantly better performance and longevity compared to standard grades, making it a wise long-term investment.

EPDM Properties & Benefits

| Property | Performance | Application Benefit |

|---|---|---|

| Weather Resistance | Excellent UV, ozone & weather resistance | Ideal for outdoor applications and solar farms |

| Temperature Range | -40°C to +120°C | Maintains elasticity in extreme conditions |

| Chemical Resistance | Stable towards hydraulic fluids, ketones, alkalis | Reliable in harsh industrial environments |

| Saltwater Resistance | High resistance to saline environments | Perfect for marine applications |

| Flexibility | Maintains elasticity across temperature ranges | Reliable, reusable sealing and protection |

| Durability | Robust, long-term performance | Reduces replacement frequency and costs |

PVC Edging Solutions

PVC (Polyvinyl Chloride) edging strips offer an excellent alternative for applications where EPDM may be overspecified. PVC provides good durability, flexibility and cost-effectiveness, making it ideal for interior applications and less demanding environments.

How to Select the Right Edging Strip

Profile Selection Guide

| Profile Type | Best For | Key Features |

|---|---|---|

| Square Profile | Flush finishes, flat surfaces | Clean aesthetic, neat edge protection |

| U-Channel Profile | Exposed panel edges, full encasement | Snug fit all around material, maximum protection |

| O-Channel Profile | Round or curved edges | Flexible, adapts to contours |

| A-Channel Profile | Asymmetric edges, angled surfaces | Specialized fit for unique applications |

| Self-Adhesive | Quick installations, interior panels | No tools required, permanent bonding |

| Reinforced | Heavy-duty, high-impact areas | Metal ribs, superior strength |

Frequently Asked Questions

What's the difference between square and U-channel edging profiles?

Square profile edging features a flat design ideal for applications needing a flush finish on flat surfaces. U-channel profiles have a U-shaped design that fully encases edges, providing a snug fit all around the material, perfect for covering exposed panel edges.

Why choose EPDM rubber over other materials?

EPDM exhibits exceptional resistance to UV, ozone, saltwater and extreme weather conditions. It maintains elasticity across wide temperature ranges (-40°C to +120°C), offers superior chemical resistance and provides long-term performance, making it ideal for outdoor, automotive, marine and solar applications.

When should I use reinforced edge trim instead of standard edging?

Choose reinforced edge trim for heavy-duty industrial applications where edges may be subject to impact, frequent contact, or mechanical stress. The metal rib reinforcement provides superior strength for protecting exposed metal edges in manufacturing facilities, commercial vehicle panels and loading bay environments.

Do I need adhesive or tools to install rubber edge trims?

No. Our standard rubber edge trims are designed for quick, tool-free installation without adhesives – they simply push onto edges for secure fit. For applications requiring permanent bonding, we also offer Self-Adhesive Edging Strips with pre-applied backing.

Can I get custom sizes for my specific application?

Yes. Vital Parts offers custom sizing, materials, and roll lengths for edging strips to meet your specific requirements. Contact our technical team on 01233 713 581 to discuss your custom needs and we can provide free samples for testing.

Ready to Find Your Perfect Edging Solution?

Our expert team is ready to help you select the right edging strips for your specific application. With years of experience and one of the UK's most comprehensive ranges, we're confident we can meet your needs.

Leave a comment