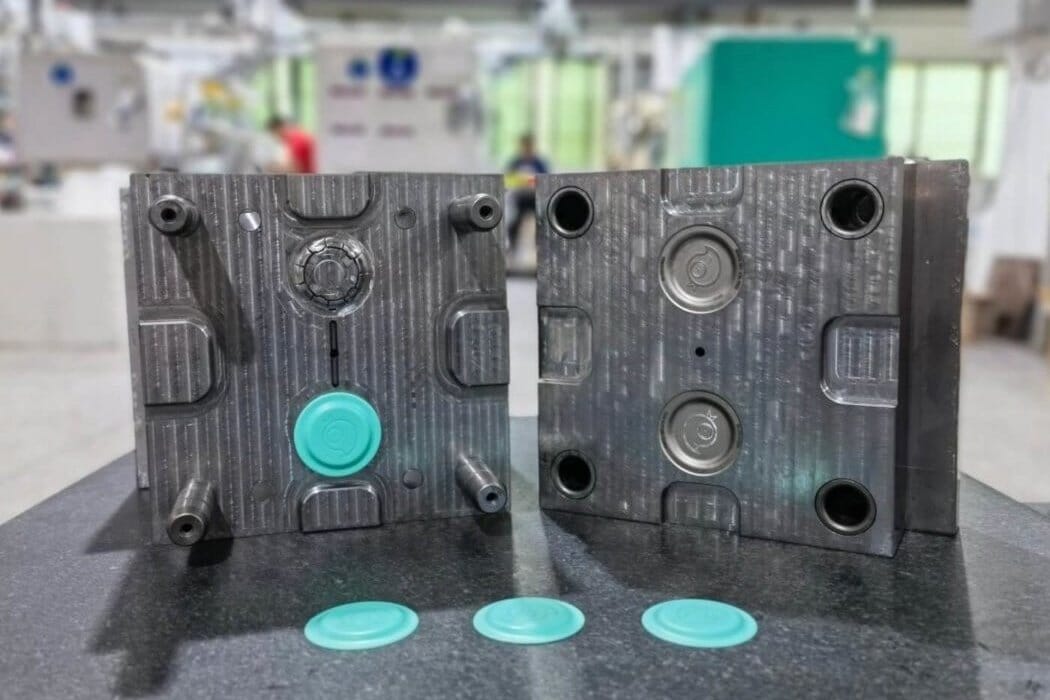

Plastic injection moulding is a precision manufacturing process that produces custom plastic components by injecting molten thermoplastic materials into specially designed moulds. This versatile injection moulding technique enables the mass production of complex plastic parts with exceptional accuracy and repeatability.

The plastic injection molding process begins by heating plastic pellets until they reach a molten state. The molten material is then injected under high pressure into a precision-engineered mould cavity. Once the plastic moulding material cools and solidifies, the finished component is ejected, ready for use or assembly.

This manufacturing method has revolutionised industries worldwide, enabling the cost-effective production of everything from automotive components and medical devices to consumer electronics and packaging solutions.

How Does the Plastic Injection Moulding Process Work?

The injection moulding process follows a precise sequence of steps to ensure consistent, high-quality results:

Key Process Steps: Clamping → Injection → Cooling → Ejection

Clamping: The two halves of the injection mould are securely clamped together using hydraulic pressure to prevent material leakage during injection.

Injection: Thermoplastic pellets are fed into a heated barrel where they're melted to the optimal temperature. A reciprocating screw then injects the molten plastic injection molding material into the mould cavity under controlled pressure.

Cooling: The injected plastic is held under pressure whilst cooling channels circulate temperature-controlled fluid around the mould, ensuring uniform cooling and preventing defects such as warping or sink marks.

Ejection: Once sufficiently cooled, the mould opens and ejector pins push the finished component from the cavity, completing the cycle.

This efficient plastic moulding process can be repeated thousands of times with remarkable consistency, making it ideal for high-volume production whilst maintaining tight tolerances and superior surface finishes.

Common Applications for Plastic Injection Moulding

The versatility of injection moulding makes it suitable for countless applications across diverse industries. Here's where you'll commonly find injection moulded components:

| Industry | Typical Applications | Common Materials |

|---|---|---|

| Automotive | Dashboard assemblies, door panels, engine covers, interior trim, lighting housings, bumper components | ABS, Polycarbonate (PC), Polysulfone (PSU), Nylon (PA), Acetal (POM) |

| Medical & Healthcare | Syringe components, diagnostic equipment, pill dispensers, surgical instruments, laboratory equipment | Polyethylene (PE), Polystyrene (PS), Polysulfone (PSU), Medical-grade PC |

| Electronics & Telecommunications | Device housings, connector components, circuit board supports, remote controls, mobile phone cases | Polycarbonate (PC), ABS, Polysulfone (PSU), Flame-retardant grades |

| Packaging | Bottles, caps, closures, containers, food packaging, cosmetic containers | Polypropylene (PP), Polyethylene (PE), Polystyrene (PS) |

| Consumer Products | Toys, household items, kitchen utensils, garden tools, furniture components | ABS, Polypropylene (PP), Polyethylene (PE) |

| Industrial & Commercial | Gears, bearings, rollers, machine components, protective housings | Nylon (PA), Acetal (POM), Engineering grades of PC and ABS |

Which Material Should I Choose for My Project?

Selecting the appropriate material for your plastic injection moulding project is crucial for achieving optimal performance and cost-effectiveness. The choice depends on your component's specific requirements:

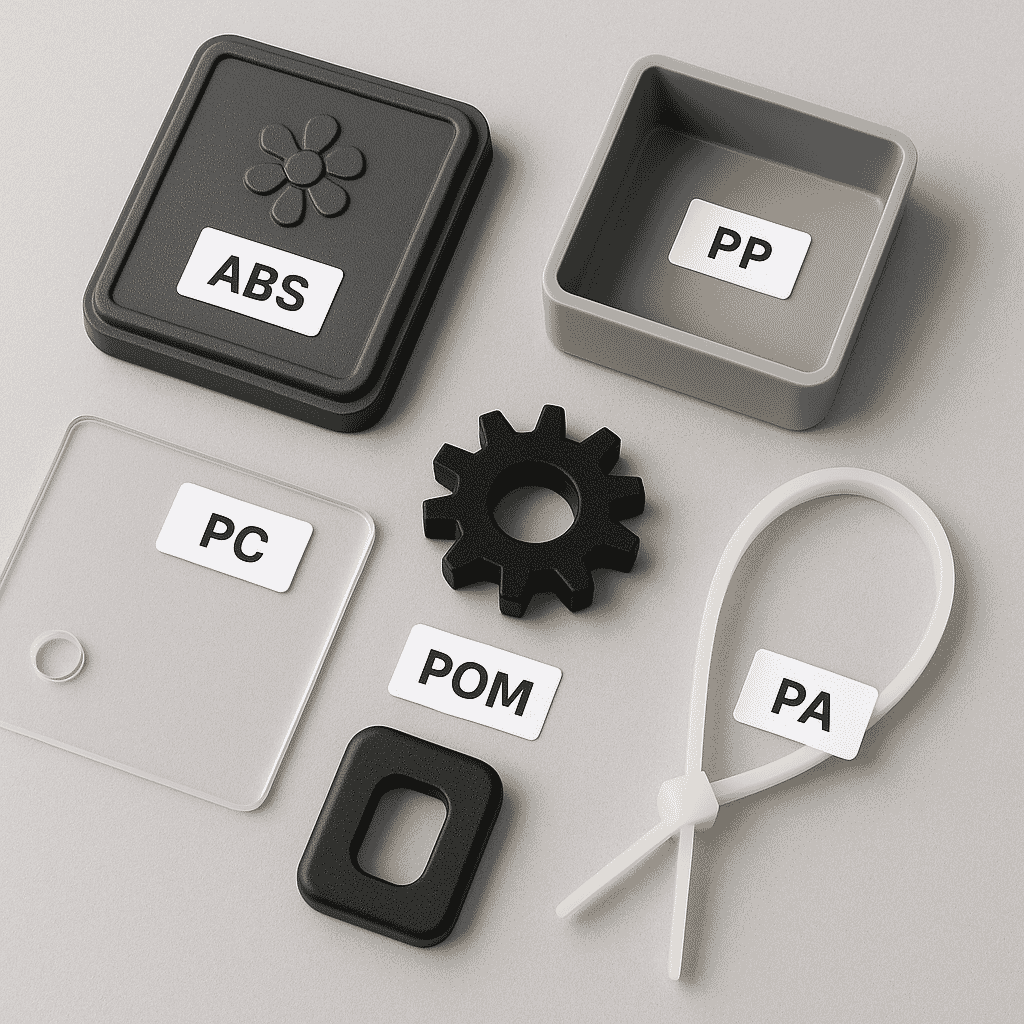

Acrylonitrile Butadiene Styrene (ABS): An excellent all-round choice offering strong impact resistance, good dimensional stability, and ease of processing. Ideal for automotive trim, electronic housings, and consumer products.

Polypropylene (PP): Lightweight, chemically resistant, and cost-effective. Perfect for packaging, automotive parts, and applications requiring flexibility or living hinges.

Polycarbonate (PC): Exceptional strength and transparency with excellent temperature resistance. Used for safety glazing, electronic components, and optical applications.

Acetal (POM): Superior dimensional stability and low friction properties make it ideal for precision gears, bearings, and mechanical components.

Nylon (PA): Outstanding wear resistance and mechanical strength. Commonly used for gears, bearings, automotive under-bonnet components, and industrial applications.

Consider environmental factors such as temperature exposure, chemical resistance requirements, UV stability, and mechanical loads when making your material selection.

Comprehensive Material Properties Guide

Understanding material characteristics is essential for successful plastic injection molding projects. Each thermoplastic offers unique properties suited to specific applications:

| Material | Key Properties & Applications |

|---|---|

| Polyethylene (PE) Low & High Density |

|

| Polypropylene (PP) |

|

| Polyvinyl Chloride (PVC) |

|

| ABS (Acrylonitrile Butadiene Styrene) |

|

| Polystyrene (PS) |

|

| Polycarbonate (PC) |

|

| Acetal (POM) |

|

| Nylon (PA) |

|

| Polysulfone (PSU) |

|

Material selection should always prioritise functional requirements over cost considerations. Our experienced team can help you identify the optimal material for your specific application requirements.

Expert Tip: At Vital Parts, we offer comprehensive material consultation as part of our custom moulding services. Our technical team, with over 60 years of combined experience, can help optimise your material selection for performance, cost, and manufacturability.

Advanced Injection Moulding Processes

HDPE Injection Moulding

High-Density Polyethylene (HDPE) injection moulding is a specialised process ideal for applications requiring exceptional chemical resistance and impact strength. HDPE's unique properties make it perfect for automotive fuel systems, chemical containers, and outdoor applications.

The HDPE plastic injection moulding process requires precise temperature control due to the material's narrow processing window. Our expertise in HDPE processing ensures optimal part quality with minimal stress and excellent surface finish.

Common HDPE applications include industrial containers, automotive components, marine hardware, and chemical processing equipment where durability and chemical resistance are paramount.

Thermoplastic Injection Moulding

Thermoplastic injection moulding represents the most versatile form of plastic moulding, utilising materials that can be repeatedly melted and reformed without degradation. This characteristic makes thermoplastics ideal for sustainable manufacturing practices.

The thermoplastic injection moulding process offers several advantages including material reclaimability, consistent properties across multiple processing cycles, and the ability to produce complex geometries with tight tolerances.

Industries benefit from thermoplastic injection moulding's versatility in automotive, electronics, medical devices, and consumer products where reliability and performance are essential.

The combination of process flexibility, material variety, and cost-effectiveness makes thermoplastic injection moulding the preferred choice for high-volume production across multiple industries.

Vital Parts Custom Moulding Services

At Vital Parts, we specialise in providing comprehensive plastic injection moulding solutions tailored to your specific requirements. Our value-added services include:

Complete Product Lifecycle Management: From initial concept through to production, our experienced team manages every aspect of your project, ensuring optimal results and cost-effectiveness.

In-House Technical Expertise: Our dedicated engineering team, with over 60 years of combined experience, provides comprehensive technical support including 3D CAD design, rapid prototyping, and design optimisation for manufacturability.

Advanced Manufacturing Techniques: We employ various moulding techniques including injection moulding, dip moulding, overmoulding, and extrusion to meet diverse application requirements.

Secondary Finishing Services: Our comprehensive finishing capabilities include trimming, washing, hole punching, and other value-added processes to deliver components ready for immediate use.

24/7 Dispatch Service: With our commitment to meeting project deadlines, we operate a 24-hour dispatch service running Monday to Sunday, ensuring your components are delivered when you need them.

Frequently Asked Questions About Plastic Injection Moulding

Ready to Start Your Injection Moulding Project?

Our expert team is ready to help you bring your custom plastic components to life. Contact us today for a comprehensive consultation and competitive quotation.

Call Our Experts Request a Quote

Leave a comment