We're proud to offer a range of in-house Custom Moulding Services, employing a mixture of cutting-edge and traditional production methods including 3D Printing, Injection Moulding and Compression Moulding. Our team of experts hold over 25 years of hands-on engineering experience across a variety of industrial applications and sectors, from design specification through to product manufacture.

Much like our range of Value Added Services we are here to work with you on your project as a full-service provider, offering you both support and consultancy on your project across the product lifecycle.

ENQUIRY

At this stage our dedicated account managers will work with you to bring your concept to life with a consultation

PROCESS

Here we will look to optimise the manufacturing process of choice, maximising operational efficiency and keeping costs low

DISPATCH

Our team are dedicated to meeting project deadlines with a 24 hour dispatch running Monday to Sunday

SUPPORT

Our technical engineering and vast product expertise guarantees a great customer experience every time

What Are The Custom Moulding Services You Offer?

The different custom moulding techniques and services we offer are summarised below, where you can learn more about individual manufacturing options. You also have the ability to enquire using the form at the bottom of the page, where your project requirements can be submitted.

Techniques At A Glance:

-

Rubber Compression Moulding

-

Polyurethane Foam Moulding

-

Metal Machined Parts

-

Rotational Moulding

-

Dip Moulding

-

Injection Moulding

-

Over Moulding

-

Extrusions

Please note that where a prototype is required prior to approval, we are able to offer 3D printed rapid prototyping at a fraction of the cost of traditional tooling

Custom Moulding Enquiry Form

Injection moulding is one of the most common processes for manufacturing products made from Plastic & Rubber. This is due to the simple and efficient nature of an injection moulded tool, which works by feeding the desired material into a hopper before being heated until liquid. Then, it is pushed through the mould before being left to cool. Once cooled, the mould is removed and out comes the finished injection moulded product.

We have worked with hundreds of companies throughout the UK and within Europe on Injection Moulding projects, working with you to bring your product to life. Our manufacturing capabilities allow us to offer a range of different press sizes, combined with an expert tool cavity layout to keep costs to a minimum.

Capabilities At A Glance

-

Ability to offer a range of different injection moulding press sizes

-

Able to reverse engineer parts and produce a tool to fit

-

Expert tool cavity layout to optimise cost efficiencies

-

Ability to offer insert and over moulding

-

Hot runner system capability

Additional Injection Moulding Capabilities:

-

Moulding

-

Rotational Moulding

What Is Over Moulding?

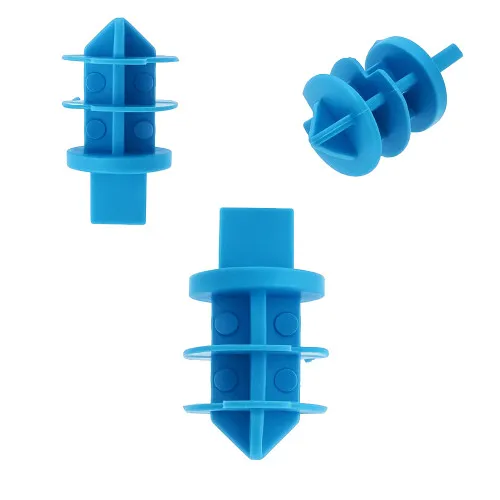

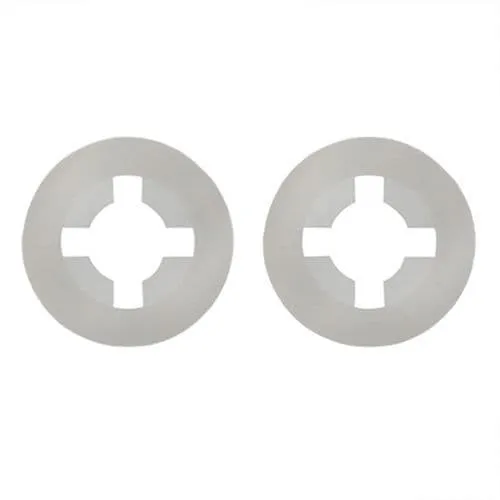

One of the most common uses of Over Moulding that you will see daily is an injection type moulding process. This is where a Plastic or Rubber is moulded over a secondary material. A common exampleexample of an Over Moulded product would be a screwdriver. This method of production allows for a more complex type of mould, enabling intricate designs for functional uses. Popular examples of products from our standard range that are produced using an Over Mould process include our Threaded Tube Inserts and Spring Threaded Tube Inserts.

What Is Rotational Moulding?

Rotational Moulding is another commonly employed production method that is used to create mainly hollow products made from Plastics. This form of moulding works by rotating the liquid plastic around the mould to give the desired shape and effect. This is a method often used to create products such as canoes, where strength is essential. Popular products from our standard range that are produced via rotational moulding include our Full Face Flange Protectors.

*For Injection Moulded parts we can take on existing tools and use them to produce your parts if the tool fits within the confines of the platen area (tool transfer) or look to reverse engineer existing parts to provide an exact solution

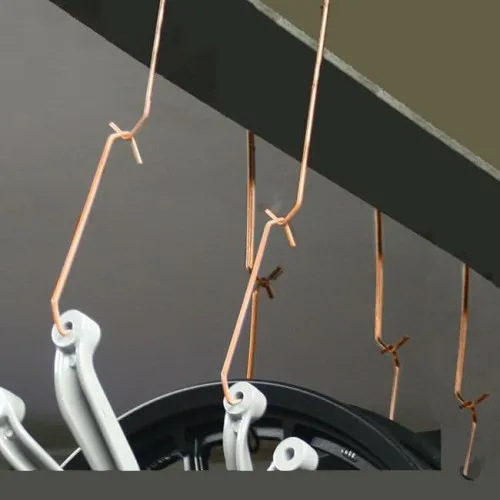

Dip Moulding is a simple and frequently employed process inside the UK for mass-produced items. Dip Moulding works by creating a to-scale mould of the product before it is heated and dipped in a liquified form of material (usually Plastic or PVC). With this type of process, the speed of entry and dip time determines the shape and thickness of the final product. The product is then cured in the oven to harden before being dipped in water. This is to give it a solid feel and finish. Once the material has cooled, the product is then blown off the mould using compressed air.

We are happy to offer a vast selection of Dip Moulding services and manufacturing processes for custom products. Simply get in touch with your requirements and design preferences for us to provide you with expert advice, along with an idea of cost and lead times.

Capabilities At A Glance:

-

Ability to offer secondary operation on Dip Moulded projects

-

Able to reverse engineer parts and produce a tool to fit

-

Expert tool cavity layout to optimise cost efficiencies

*Please note that dip moulding is compatible with a number of secondary processes such as rotational moulding and over moulding to achieve a different finish

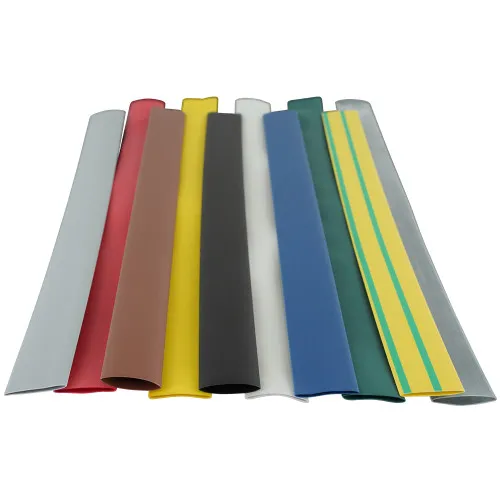

Extrusion Moulding is a high volume manufacturing process that is typically used for Plastic and Rubber products. The process involves the creation of a profile to keep the material uniform. Heated plastic is then passed through the profile to give it a specific shape and characteristic. This method of moulding is often used to create simple designs such as beams, pipes and tubing. It is one of the most efficient ways to mould basic Plastic or Rubber designs. Products from our standard range that use Extrusion Moulding as a production method include our range of Edging Strips.

We are proud to offer custom extrusions to make your product come to life. If you are interested in getting your product made by us, don't hesitate to fill out the form below and get a quick quote from us.

Alongside our standard moulding services, we are pleased to also offer a range of additional manufacturing services that can help to support your project - from start to finish. We can also accommodate to a range of typical product certifications and standards such as PPAP and Certificates Of Conformity, undertaking relevant testing as appopriate for your particular application.

Other services we can offer:

-

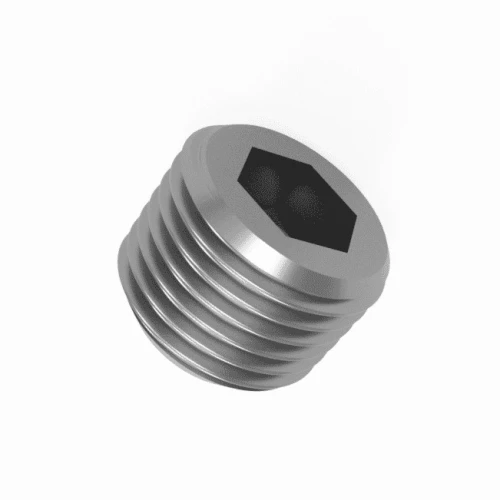

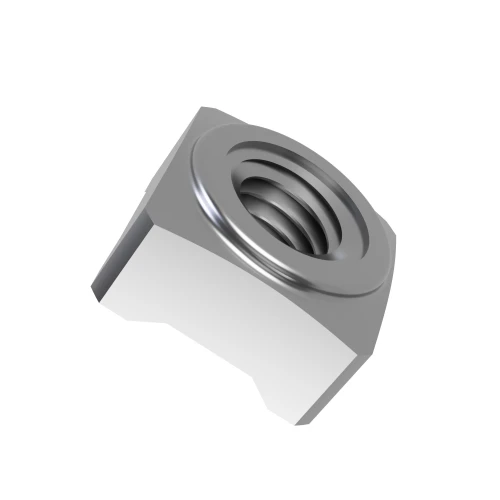

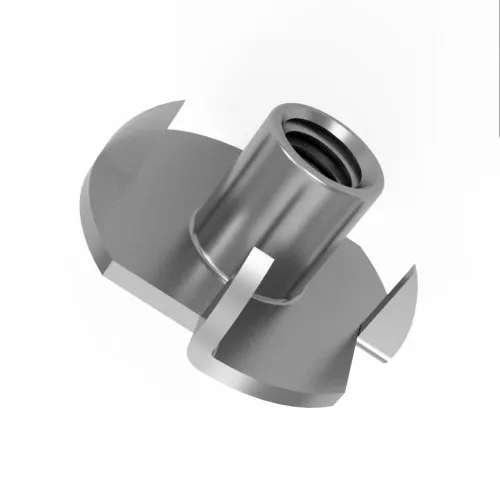

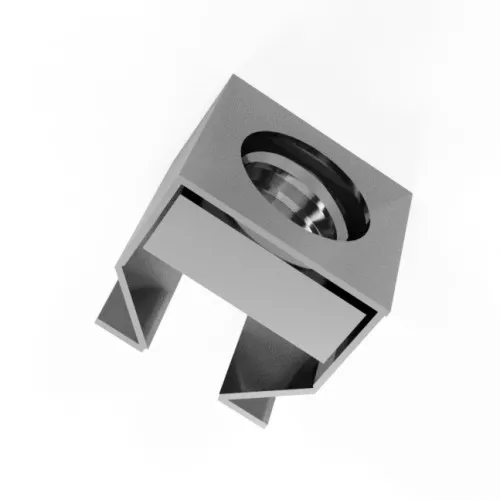

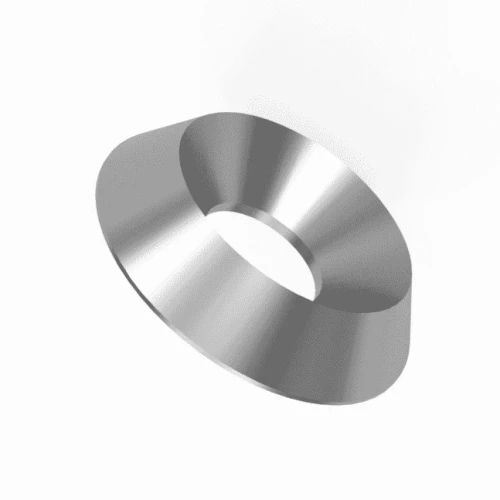

Metal Machined Parts - We have the capability to design, develop and manufacture metal components using both stamping technologies and metal machining, including finishing in a wide variety of finishes

-

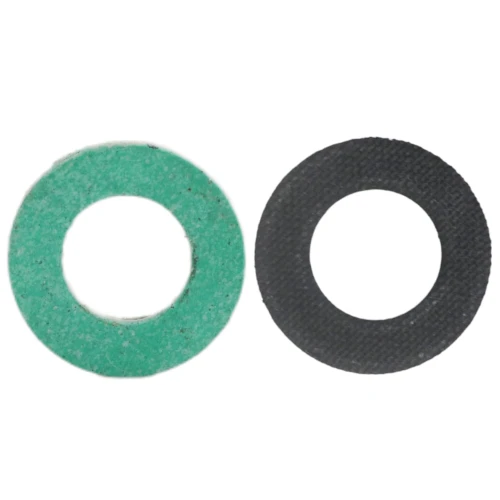

Rubber Compression Moulding - Compression Moulding is a great option for low cost and low complexity tooling, recommended for low volume requirements where Rubber is a suitable material

-

Polyurethane Foam Moulding - Polyurethane Foam Mouldings are flexible foam mouldings that can be produced into almost any shape and complexity, with a varying range of colours, hardness and other physical characteristics

-

Product Development And Prototyping - We can either take a drawing from you of a complete part, or assist with the design of a new product. Our offering includes part design for maximum efficacy with minimal cost (part cost management), mould flow analysis, FMEA and complete project management including material selection assistance, in house 3D CAD design capability, production of 2D technical drawing for sign off and approval, 3D printing which gives rapid proof of concept and fit

*Our in house 3D printing capabilities allow for instant feedback on design with minimal costs, speeding up design process and design modification times.

*For Injection Moulded prototypes we can offer low cost/low carbon non-hardened steel (P20 or similar) or Aluminium tool (prototype tools) with low production runs of typically up to 1000 pcs used for proof of fit, function & concept.

To further improve the service we are able to offer our customers, we have in-house experience with material selection and have the capability to support with materials ranging from commodity through to engineering plastics and beyond with exotics or metal replacement grades. We are also able to offer coloured versions of any standard part, offering a wide range of standard colours as well as having RAL colour-matching capability.

Experience With The Following Materials:

| Polymers | Elastomers |

|---|---|

|

ABS (Acrylonitrile Butadiene Styrene) |

Silicone |

|

PS (Polystyrene) |

EPDM |

|

PP (Polypropylene) |

Nitrile |

|

PE (Polyethylene) |

Natural Rubber |

|

PVC (Poly Vinyl Chloride) |

Neoprene |

|

PA (Polyamides) |

PVC (Flexible Grades) |

|

POM (Polyoxymethylene) |

SBR |

|

PPS (Polyphenylene Sulphide) |

Butyl |

|

LCP (Liquid Crystal Polymer) |

FKM |

|

PEEK (Polyether Ether Ketone) |

Viton (R) |