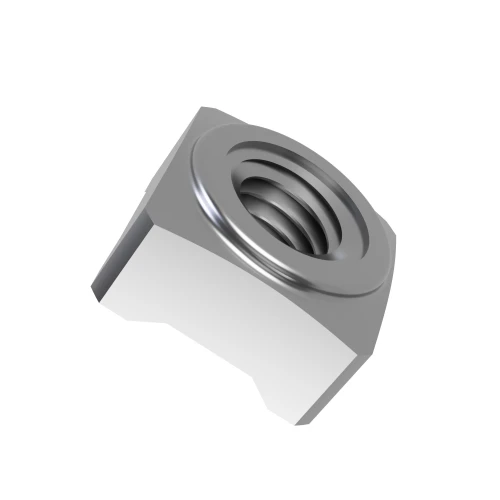

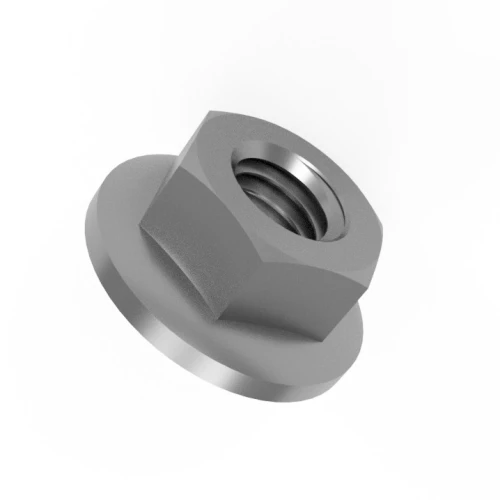

Flanged Hex Nuts

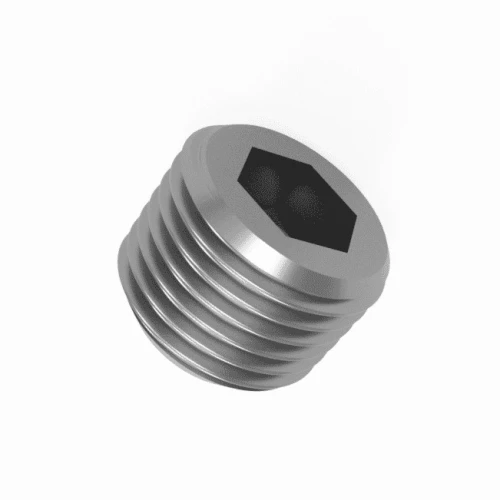

Our flanged hex nuts provide a reliable fastening solution for engineering, construction and automotive applications across the UK. The integrated flange creates a wider bearing surface than a standard hex nut, spreading the load more evenly and increasing clamping force. Manufactured from high quality A2 and A4 stainless steel, these nuts offer excellent corrosion resistance for indoor and outdoor use, making them ideal wherever a durable flange head nut is required.

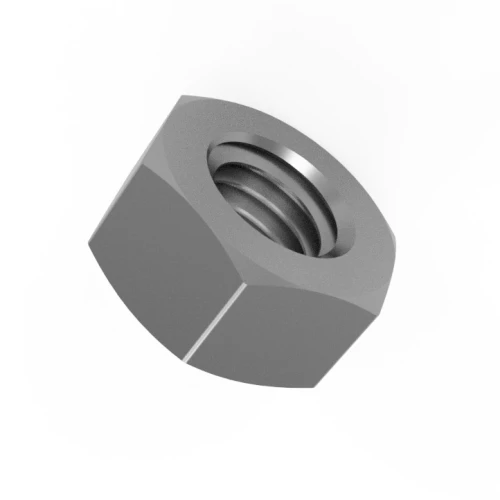

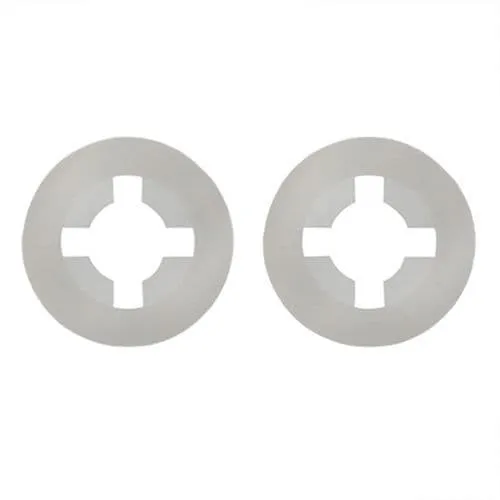

What Are Flanged Nuts?

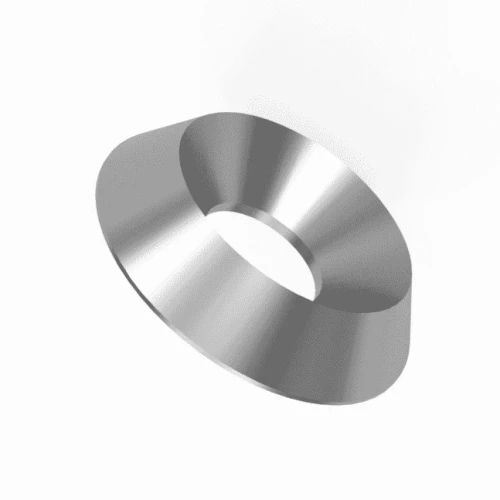

Flange nuts are standard hexagonal nuts with a built in washer like flange at the base. This flange distributes pressure over a larger area, helping to prevent damage to the mating surface and reducing the risk of pull through on softer materials. They remove the need for a separate washer in many assemblies and are widely used in automotive, machinery and structural fabrications.

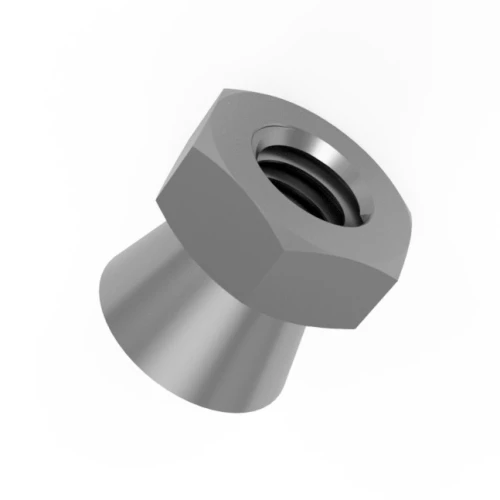

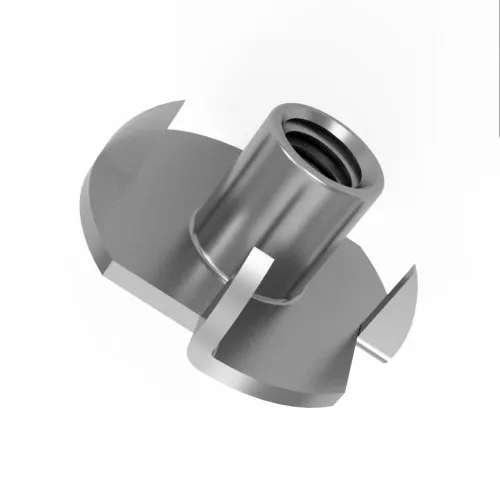

Serrated and Non Serrated Options

- Serrated flanged nuts: Feature serrations on the underside of the flange which bite into the mating surface. This increases resistance to loosening caused by vibration or shock and is suited to high vibration environments such as engines, drivetrains and heavy equipment.

- Non serrated flanged nuts: Provide a smooth bearing surface for general purpose use where vibration levels are moderate. They offer improved load distribution compared with a standard hex nut while protecting painted or plated surfaces.

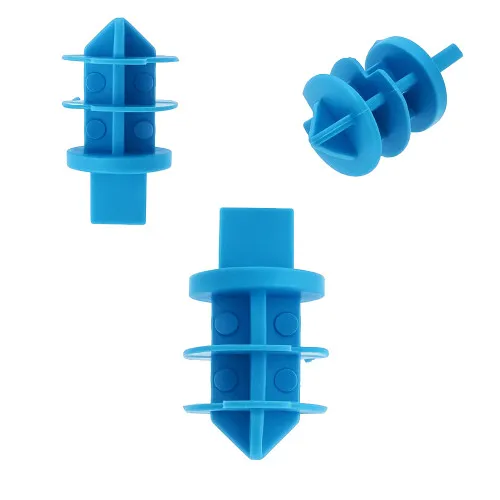

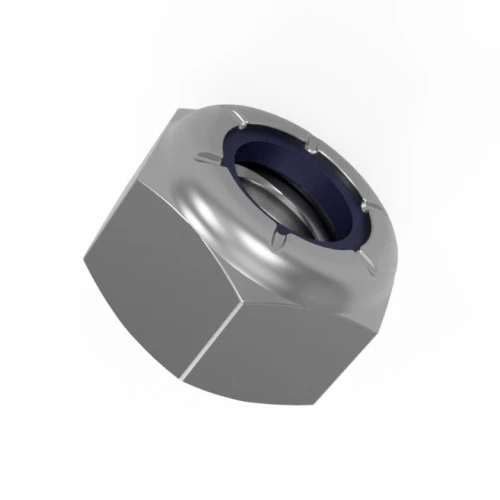

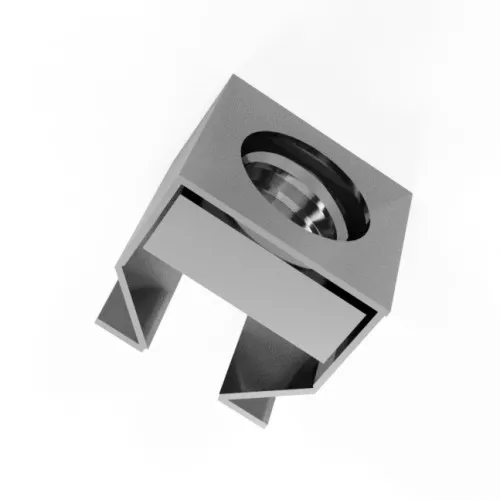

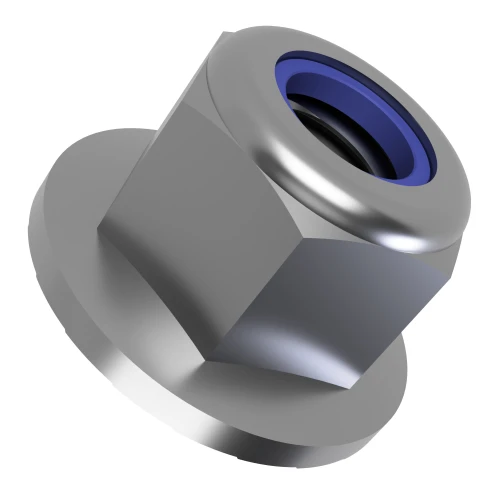

Flanged Nyloc Nuts

For applications needing extra security, flanged nyloc nuts incorporate a nylon insert within the nut. As the nut is tightened the insert deforms slightly, creating friction on the bolt thread and resisting loosening in service. This combination of a nylon insert and integrated flange is a popular choice where a locking flange head nut is required without additional washers or locking devices.

Typical UK Applications

- Automotive: Securing brackets, suspension components and engine bay fixings where vibration resistance is essential.

- Aerospace and transport: Used in assemblies that experience constant movement and thermal cycling.

- Heavy machinery and plant: Maintaining critical joints on construction equipment, agricultural machinery and industrial plant.

- General fabrication: Ideal for bolted joints in steelwork, frames, enclosures and guarding where a clean, integrated flange nut solution is preferred.

For assistance selecting the correct flanged hex nut size, material or serration style for your application, contact our technical team who can advise on performance, standards and compatibility with your existing fasteners.

Need Support?

Frequently Asked Questions

What are flanged hex nuts used for?

A flanged hex nut is a specially designed hex nut that includes an integrated flat edge at its base. The flat edge is known as a flange and in many ways serves the same purpose as a washer. For this reason, you can think of a flange nuts as being similar in application to a standard nuts with a washer placed underneath. The integration of the washer on a flanged nut improves load distribution, offers enhanced stability and helps to increase both the ease and speed of application. They may also offer cost savings when compared to purchasing a hex nut and washer separately. This makes them a popular component for use in fastening industrial machinery, securing plumbing and pipework systems, and the assembly of structures.

What are flanged nuts also known as?

The most commonly used terms to refer to flanged hex nuts are flange nuts or simply, flanged nuts. They might also be described as flange head nuts and some people call them collar nuts. More technically minded customers will also tend to call them by their DIN standard. For our range of flanged nuts this would be the din6923 or din6926 varieties.

What types of flanged hex nuts do you sell?

We are proud to offer the most popular styles of flange nuts to the UK market and our international customers. We stock flanged hex nuts, serrated flange nuts and flange nyloc nuts. The serrated nuts have small ridges cut into the circumference of the flange. These are designed to bite into the surface of the application as the nut is tightened on its thread. This creates friction and a locking effect similar to what is found in locking nuts. This provides an effective anti vibration solution for use in applications exposed to constant vibrations, that may cause a nut to loosen over time. Flange nyloc nuts are similar to nyloc nuts and utilise a nylon insert inside the thread of the nut to help provide friction and combat vibration loosening. Flange nyloc nuts have the addition of the washer like rim at the bottom of the nut, effectively combining a hex nut and washer in one component. Both serrated flange nuts and flange nyloc nuts provide effective options for fastening components in high vibration applications such as the automotive and aerospace industries, as well as on heavy machinery. The addition of the flange helps flanged nyloc nuts to offer enhanced stability and load distribution than standard nyloc nuts, thanks to the increased surface area that the flange provides.

What thread sizes of flange nuts do you offer?

We supply flange nuts in metric thread sizes ranging from M3 up to M16. However, if you need a size that isn't listed or require non-metric sizing, please contact us. Our most popular offerings are the M8 flange nut and M6 flange nut. Customers also commonly purchase M10 flange nuts and M12 flange nuts for their projects.

How do I measure a flange nut?

There are a few dimensions you will need to accurately assess when measuring a flange hex nut: thread size, flange diameter, flange thickness and across flats width. To get an accurate recording you will need to use a calliper, as rulers and tape measures are unlikely to accurately measure components. You can measure the thread size of the flange nut by placing the callipers across the diameter of the hole in the nut. Next, proceed to measure the whole of the nut's flange at its widest point. Now use the callipers to measure the thickness from the top of the flange to the bottom. Finally, measure the "across flats", this means the distance between one flat side of the hex nut and its opposite side. These dimensions will give you enough information to order an equivalent replacement, but you should also identify the material and grade that it is manufactured from, to ensure an equivalent replacement.

Do flange nuts need washers?

The flange on a flanged nut provides a rim at the base of the nut which offers similar mechanical properties to a washer. It increases the surface area in contact with the fastened application and increases stability and load distribution. It is not necessary to use washers with flange nuts, and this is one of the main advantages of using flanged hex nuts. Not having to add the nut and the washer separately to an application makes installation faster and less effort. Flange nuts may also work out cheaper than purchasing a hex nut and a washer separately, providing a cost advantage.

What is the difference between a flange nut and a lock nut?

A flange nut is a term used to describe any nut with a flat surface at the base of the nut. A lock nut is used to describe any nut with a locking mechanism that is normally used to combat nut loosening in high vibration applications. Both terms refer to types of nuts, however, they are not mutually exclusive. For example, our serrated flange nuts and flange nyloc nuts are examples of nuts that are both flanged nuts and lock nuts. The serrated flange nut uses teeth to lock into the application's surface, and the flanged nyloc nuts use a nylon insert that applies friction to the application's thread. When tightened, both create a locking mechanism that is effective at preventing the nut from loosening. Both serrated flange nuts and flange nyloc nuts have flanges but not all lock nuts have flanges. Flanges act as a built in washer for the nut and that may bring advantages that are desirable for some applications.

What are flanged hex nuts used for?

A flanged hex nut is a specially designed hex nut that includes an integrated flat edge at its base. The flat edge is known as a flange and in many ways serves the same purpose as a washer. For this reason, you can think of a flange nuts as being similar in application to a standard nuts with a washer placed underneath. The integration of the washer on a flanged nut improves load distribution, offers enhanced stability and helps to increase both the ease and speed of application. They may also offer cost savings when compared to purchasing a hex nut and washer separately. This makes them a popular component for use in fastening industrial machinery, securing plumbing and pipework systems, and the assembly of structures.

What are flanged nuts also known as?

The most commonly used terms to refer to flanged hex nuts are flange nuts or simply, flanged nuts. They might also be described as flange head nuts and some people call them collar nuts. More technically minded customers will also tend to call them by their DIN standard. For our range of flanged nuts this would be the din6923 or din6926 varieties.

What types of flanged hex nuts do you sell?

We are proud to offer the most popular styles of flange nuts to the UK market and our international customers. We stock flanged hex nuts, serrated flange nuts and flange nyloc nuts. The serrated nuts have small ridges cut into the circumference of the flange. These are designed to bite into the surface of the application as the nut is tightened on its thread. This creates friction and a locking effect similar to what is found in locking nuts. This provides an effective anti vibration solution for use in applications exposed to constant vibrations, that may cause a nut to loosen over time. Flange nyloc nuts are similar to nyloc nuts and utilise a nylon insert inside the thread of the nut to help provide friction and combat vibration loosening. Flange nyloc nuts have the addition of the washer like rim at the bottom of the nut, effectively combining a hex nut and washer in one component. Both serrated flange nuts and flange nyloc nuts provide effective options for fastening components in high vibration applications such as the automotive and aerospace industries, as well as on heavy machinery. The addition of the flange helps flanged nyloc nuts to offer enhanced stability and load distribution than standard nyloc nuts, thanks to the increased surface area that the flange provides.

What thread sizes of flange nuts do you offer?

We supply flange nuts in metric thread sizes ranging from M3 up to M16. However, if you need a size that isn't listed or require non-metric sizing, please contact us. Our most popular offerings are the M8 flange nut and M6 flange nut. Customers also commonly purchase M10 flange nuts and M12 flange nuts for their projects.

How do I measure a flange nut?

There are a few dimensions you will need to accurately assess when measuring a flange hex nut: thread size, flange diameter, flange thickness and across flats width. To get an accurate recording you will need to use a calliper, as rulers and tape measures are unlikely to accurately measure components. You can measure the thread size of the flange nut by placing the callipers across the diameter of the hole in the nut. Next, proceed to measure the whole of the nut's flange at its widest point. Now use the callipers to measure the thickness from the top of the flange to the bottom. Finally, measure the "across flats", this means the distance between one flat side of the hex nut and its opposite side. These dimensions will give you enough information to order an equivalent replacement, but you should also identify the material and grade that it is manufactured from, to ensure an equivalent replacement.

Do flange nuts need washers?

The flange on a flanged nut provides a rim at the base of the nut which offers similar mechanical properties to a washer. It increases the surface area in contact with the fastened application and increases stability and load distribution. It is not necessary to use washers with flange nuts, and this is one of the main advantages of using flanged hex nuts. Not having to add the nut and the washer separately to an application makes installation faster and less effort. Flange nuts may also work out cheaper than purchasing a hex nut and a washer separately, providing a cost advantage.

What is the difference between a flange nut and a lock nut?

A flange nut is a term used to describe any nut with a flat surface at the base of the nut. A lock nut is used to describe any nut with a locking mechanism that is normally used to combat nut loosening in high vibration applications. Both terms refer to types of nuts, however, they are not mutually exclusive. For example, our serrated flange nuts and flange nyloc nuts are examples of nuts that are both flanged nuts and lock nuts. The serrated flange nut uses teeth to lock into the application's surface, and the flanged nyloc nuts use a nylon insert that applies friction to the application's thread. When tightened, both create a locking mechanism that is effective at preventing the nut from loosening. Both serrated flange nuts and flange nyloc nuts have flanges but not all lock nuts have flanges. Flanges act as a built in washer for the nut and that may bring advantages that are desirable for some applications.

What are the advantages of flanged M8 nuts over standard hex nuts?

Flanged M8 nuts offer several significant advantages over standard hex nuts, making them ideal for demanding applications. The integrated flange provides a larger bearing surface area, distributing clamping loads more evenly across the fastened material and reducing the risk of surface damage or deformation. This larger contact area often eliminates the need for separate washers, streamlining assembly and reducing component count. Flanged M8 nuts also offer improved vibration resistance due to the increased friction surface, making them particularly valuable in automotive, machinery, and structural applications where loosening could be catastrophic. The flange design provides better grip against smooth surfaces and can accommodate slight misalignments better than standard nuts. Available in both standard and nyloc (self-locking) variants, flanged M8 nuts represent a premium fastening solution where reliability and performance are paramount.

What is the difference between a flanged hex nut and a flange head nut?

In most day to day usage a flanged hex nut and a flange head nut describe the same type of product: a hexagonal nut with an integrated washer like flange at the base. The term "flange head nut" is often used by buyers who are focused on the larger bearing surface around the head of the nut, while "flanged hex nut" is more common in engineering catalogues. Both provide improved load spreading and reduced need for separate washers.

When should I use a flange head nut instead of a standard hex nut and washer?

A flange head nut is recommended when you want faster assembly, fewer components and better resistance to loosening under vibration. Because the flange spreads the load over a wider area it can help prevent damage to painted or softer surfaces and reduces the risk of the nut embedding into the material. In high vibration environments, using a serrated or nyloc flange head nut can offer a more secure fixing than a standard hex nut and loose washer combination.

How fast can I get my order?

Need your parts tomorrow? Our rapid same day dispatch has got you covered! Simply place your order before 4pm Mon-Thurs or 2pm Friday and select our Next Day Delivery service in the shopping cart. We also offer Guaranteed AM delivery when required, in addition to a Saturday delivery option.

If you don't mind waiting, we have a Free delivery method for orders over £30, and an economic £4.85 2nd Class delivery for orders between £20-£30.

Can I get a Free Sample?

Free Samples can be requested through our product pages, displayed in the sizing table beside the product you require. Please note you can always give us a call on 01233 713 581 or contact us on Live Chat to discuss samples.

Do I need to Sign Up for an account?

You do not need to sign up to place an order, but it is recommended if you'd like to gain loyalty points, giving discount off future orders. To learn more about loyalty points, please view our rewards scheme page.

I am not sure what parts I need?

If you're unsure which part you need then please do not hesitate to give one of our friendly Sales Team a call on 01233 713 581 and they can assist you. Alternatively, we're active on Live Chat during office hours. You can open this using the button in the bottom right corner of the website. Alternatively, you can write to us using our contact form.

Do you offer Returns on Products?

We offer a return period on all of our products to give you peace of mind, to view our policies and learn more about this process should it be required, please see our returns policy page.

Can you supply different colours of this product?

In most cases we have the facilities to offer you different colours of a product, specific to your requirements. Minimum order quantities may apply depending on the manufacturing technique in question, but please get in touch with any queries you may have.

Is there a minimum order value?

Please note that there is a minimum order value of £10 through our website (inclusive of VAT).

If you're new to our website you may want to check out our frequently asked questions section for answers to common customer queries.

What do these abbrievations mean?

While browsing the website you may come across abbreviations used for material names that you are unfamiliar with. You can find an explanation for these in our material abbreviations guide.