Anti Vibration

Our selection of Anti Vibration Products are manufactured from high quality, RoHS compliant materials. These include natural rubber and zinc plated steel to provide a high performance. Each solution is designed specifically to reduce excess vibrations or shock, as a common by-product of modern machinery and mechanical installations. For example, within Combustion Engines, Transit Cases, Generators and many more.

The majority of our Anti Vibration Hardware is capable of resisting both compression and sheer force. It keeps them competitive with any market leading alternative. This is thanks to the thorough testing processes used during manufacturing.

As a manufacturer of these Anti Vibration Solutions, we are able to provide a number of other premium materials across both Mount and Buffer styles. These include high temperature rubber and stainless steel, which are available upon request. We suggest following our quick step guide linked below if you are unsure of the factors to consider before choosing the best Anti Vibration solution.

Click here for our quick step guide to Anti Vibration to make sure you choose the right size needed.

Why Choose Our Anti Vibration Products?

- Manufactured using a quality selection of RoHS compliant materials

- Available in premium stainless steel and heat resistant rubber

- Compatible with 1000's of Industrial and Commercial uses

- Threaded for an easy and secure fitment

Common Applications Of These Solutions:

- As mounts for threaded legs

- As buffers in between moving parts

Need help with our Anti Vibration Products? Give a member of team a call on 01233 713 581

Categories

-

Plugs & Stoppers

-

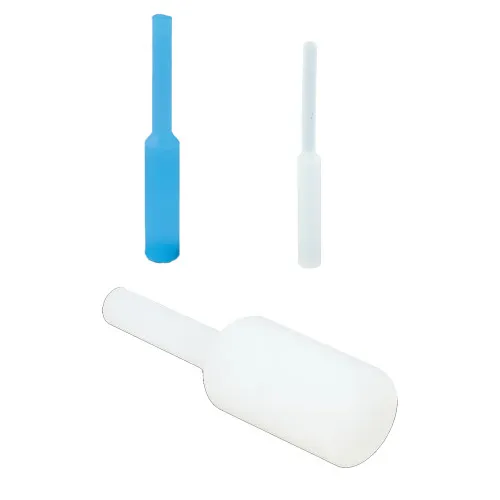

Tapered Rubber Plugs

Tapered Rubber Plugs -

Blanking Plugs

Blanking Plugs -

Ventilation Plugs

Ventilation Plugs -

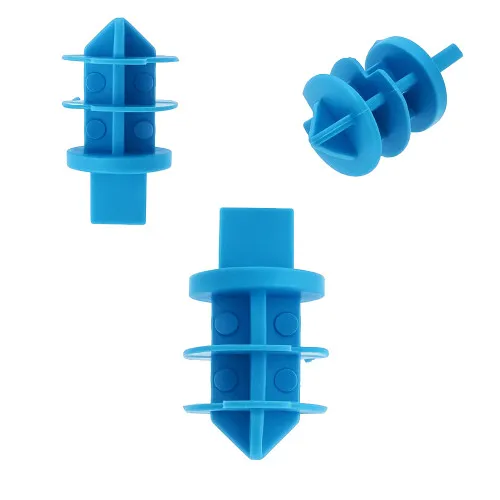

Fir Tree Plugs

Fir Tree Plugs -

Snap Fit Bushes

Snap Fit Bushes -

Liquid Tight Plugs

Liquid Tight Plugs -

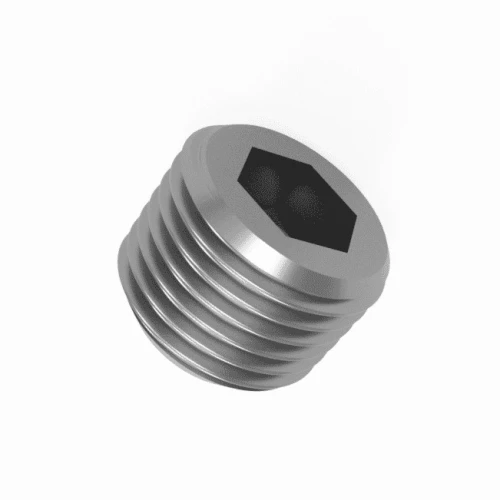

Threaded Plugs

Threaded Plugs -

Threaded Sealing Plugs

Threaded Sealing Plugs -

Reversible Tapered Plugs

Reversible Tapered Plugs -

Washer Masking Plugs

Washer Masking Plugs -

Silicone Tapered Plugs

Silicone Tapered Plugs -

Silicone Ribbed Plugs

Silicone Ribbed Plugs -

Silicone Plugs With Handle

Silicone Plugs With Handle -

Silicone Step Plugs

Silicone Step Plugs -

Silicone Pull Plugs

Silicone Pull Plugs -

Silicone Thread Masking Plugs

Silicone Thread Masking Plugs -

Barrel Plugs

Barrel Plugs -

Cylindrical Pull Tab Plugs

Cylindrical Pull Tab Plugs -

Finned Pull Tab Plugs

Finned Pull Tab Plugs -

Round Tube Plugs

Round Tube Plugs -

Snap Fit Hole Plugs

Snap Fit Hole Plugs -

Ribbed Pipe End Plugs

Ribbed Pipe End Plugs -

Door Stoppers

Door Stoppers -

Finned Hole Plugs

Finned Hole Plugs -

Silicone Double Flange Plugs

Silicone Double Flange Plugs -

Silicone Flange Plugs

Silicone Flange Plugs -

Silicone Washer Plugs

Silicone Washer Plugs -

Plastic End Plugs

Plastic End Plugs -

Stainless Steel Socket Pipe Plugs DIN 906

Stainless Steel Socket Pipe Plugs DIN 906

-

-

Furniture & Chair Feet

-

Adjustable Feet

-

Slotted Head Adjustable Feet

Slotted Head Adjustable Feet -

Rubber Adjustable Feet

Rubber Adjustable Feet -

Stainless Steel Adjustable Feet

Stainless Steel Adjustable Feet -

Ready To Install Sets

Ready To Install Sets -

One Piece Adjustable Feet

One Piece Adjustable Feet -

General Adjustable Feet

General Adjustable Feet -

Low Profile Adjustable Feet

Low Profile Adjustable Feet -

Machinery Mounting Feet

Machinery Mounting Feet -

Weight Rated Articulated Feet

Weight Rated Articulated Feet -

Heavy Duty Tilting Feet

Heavy Duty Tilting Feet -

Tilting Adjustable Feet

Tilting Adjustable Feet -

Metal Adjustable Feet

Metal Adjustable Feet -

Economic Adjustable Feet

Economic Adjustable Feet -

Allen Key Adjustable Feet

Allen Key Adjustable Feet -

Anti-Vibration Levelling Feet

Anti-Vibration Levelling Feet -

Balance Feet

Balance Feet -

Polyamide Adjustable Feet

Polyamide Adjustable Feet -

Pozi Base Adjustable Feet

Pozi Base Adjustable Feet -

Hexagon Base Feet

Hexagon Base Feet -

Threaded Fittings & Fixings

Threaded Fittings & Fixings

-

-

Cable Management

-

Cable Glands

Cable Glands -

Strain Relief

Strain Relief -

Rubber Grommets

Rubber Grommets -

Cable Ties

Cable Ties -

Blanking Plugs

Blanking Plugs -

Cable Clips

Cable Clips -

Cable Tie Mounts

Cable Tie Mounts -

Velcro Cable Management

Velcro Cable Management -

Aluminium Cable Clips

Aluminium Cable Clips -

Braided Cable Sleeving

Braided Cable Sleeving -

Multi Cable Clips

Multi Cable Clips -

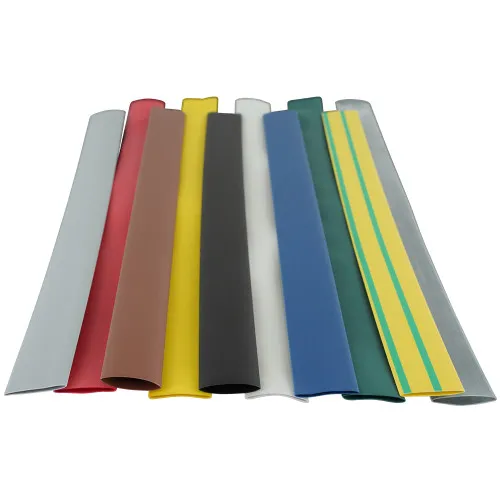

PVC Cable Sleeving

PVC Cable Sleeving -

Spiral Cable Wrap

Spiral Cable Wrap -

Heat Shrink Sleeves

Heat Shrink Sleeves -

Plastic Grommet Strips

Plastic Grommet Strips -

Adhesive Lined Heatshrink

Adhesive Lined Heatshrink -

Heat Shrink Caps

Heat Shrink Caps -

Nylon P Clips

Nylon P Clips -

Nylon P Clamps

Nylon P Clamps -

Rubber Grommet Strips

Rubber Grommet Strips -

Desk Cable Tidies

Desk Cable Tidies

-

-

Bolts and Screws

-

Hex Head Screws and Bolts

Hex Head Screws and Bolts -

Cap Screws

Cap Screws -

Countersunk Screws

Countersunk Screws -

Button Screws

Button Screws -

Pan Head Machine Screws

Pan Head Machine Screws -

Cheese Head Slotted Screws

Cheese Head Slotted Screws -

Security Fasteners

Security Fasteners -

Self Tapping Screws

Self Tapping Screws -

Wood Screws

Wood Screws -

Screws for Plastic

Screws for Plastic -

Knurled Fasteners

Knurled Fasteners -

Shoulder Bolts

Shoulder Bolts -

Grub Screws

Grub Screws -

Threaded Rod (All Thread)

Threaded Rod (All Thread) -

Weld Studs

Weld Studs -

Number Plate Screws

Number Plate Screws -

Nylon Screws & Bolts

Nylon Screws & Bolts -

Stainless Steel Bolts By Metric Thread Size

Stainless Steel Bolts By Metric Thread Size -

Small Bolts

Small Bolts -

Large Bolts

Large Bolts -

Industrial Hardware

Industrial Hardware

-

-

Washers

-

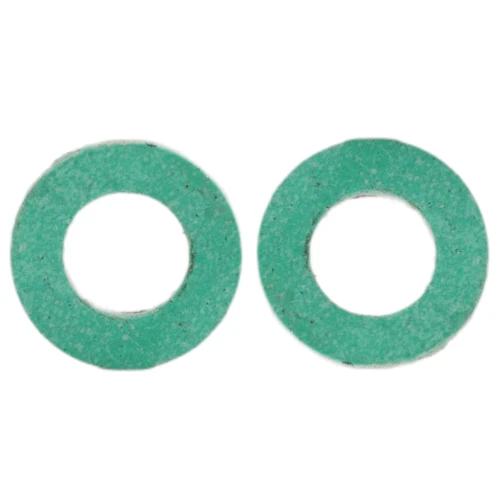

Rubber Washers

Rubber Washers -

Nylon Washers

Nylon Washers -

PTFE Washers

PTFE Washers -

Silicone Washers

Silicone Washers -

Stainless Steel Flat Washers

Stainless Steel Flat Washers -

Stainless Steel Spring Washers

Stainless Steel Spring Washers -

Stainless Steel Curved Washers

Stainless Steel Curved Washers -

Stainless Steel Serrated Washers

Stainless Steel Serrated Washers -

Stainless Steel Tab Washers

Stainless Steel Tab Washers -

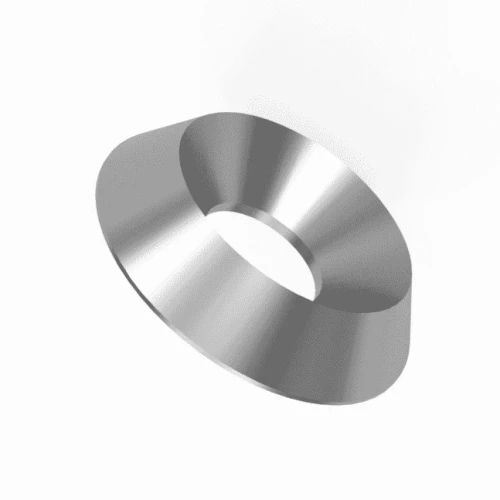

Stainless Steel Finishing Washers

Stainless Steel Finishing Washers -

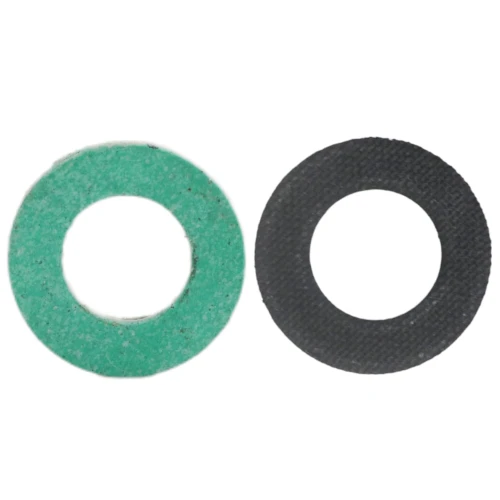

Bonded Sealing Washers

Bonded Sealing Washers -

Red Fibre Washers

Red Fibre Washers -

Peek Washers

Peek Washers -

EPDM WRAS Washers

EPDM WRAS Washers -

Fibre WRAS Washers

Fibre WRAS Washers -

FKM Washers

FKM Washers -

WRAS Washers

WRAS Washers -

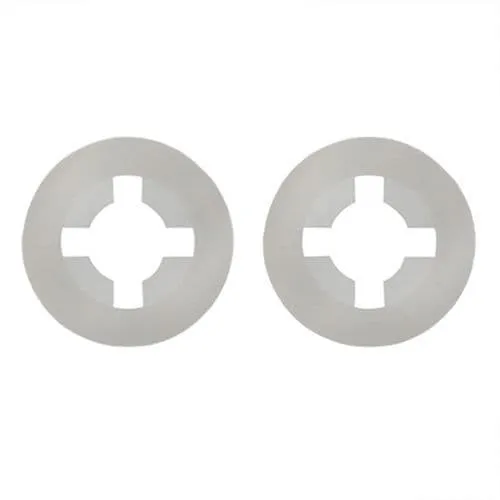

Anti-Loss Washers

Anti-Loss Washers -

Finishing Washers

Finishing Washers -

Headboard Washers

Headboard Washers -

Saddle Washers

Saddle Washers

-

-

Industrial Hardware

-

Hinges

Hinges -

Camlocks

Camlocks -

Latches

Latches -

Detent Pins

Detent Pins -

Index Plungers

Index Plungers -

Clamping Handles

Clamping Handles -

Bridge Handles

Bridge Handles -

Pull Handles

Pull Handles -

Threaded Handwheels

Threaded Handwheels -

Wing Screws & Knobs

Wing Screws & Knobs -

Knurled Thumbscrews

Knurled Thumbscrews -

Ball Knobs

Ball Knobs -

Control Handwheels

Control Handwheels -

Door Bolts

Door Bolts -

Adjustable Feet

Adjustable Feet -

Furniture Fixings

Furniture Fixings -

Plastic & Rubber Grips

Plastic & Rubber Grips -

Roof Support Systems

Roof Support Systems -

Push Fit Knobs

Push Fit Knobs -

Edging Strips

Edging Strips

-

-

Adhesive Tapes

-

PTFE Tape

PTFE Tape -

Packing Tape

Packing Tape -

Fragile Tape

Fragile Tape -

Cloth Tape

Cloth Tape -

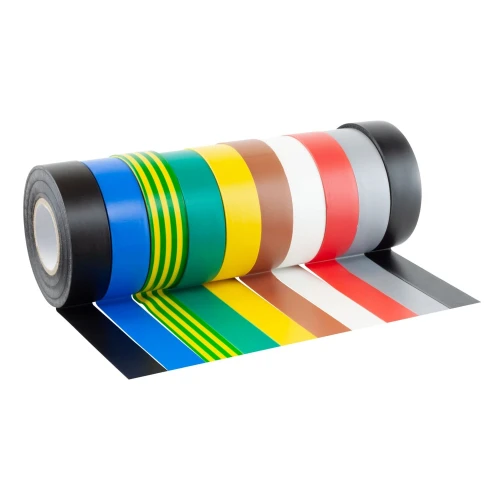

PVC Electrical Insulation Tape

PVC Electrical Insulation Tape -

Floor Marking Tape

Floor Marking Tape -

Safety Hazard Warning Tape

Safety Hazard Warning Tape -

Underground Cable Warning Tape

Underground Cable Warning Tape -

Non Slip Tape

Non Slip Tape -

Non-Adhesive Barrier Tape

Non-Adhesive Barrier Tape -

Double Sided Foam Tape

Double Sided Foam Tape -

UV Resistant Blue Masking Tape

UV Resistant Blue Masking Tape -

High Temp Crepe Tape

High Temp Crepe Tape -

Low Tack Paper Masking Tape

Low Tack Paper Masking Tape -

Aluminium Foil Tape

Aluminium Foil Tape -

Self Amalgamating PVC Tape

Self Amalgamating PVC Tape -

Self Amalgamating Silicone Tape

Self Amalgamating Silicone Tape -

Self Amalgamating EPR Tape

Self Amalgamating EPR Tape -

Fleece Tape

Fleece Tape -

Matte Cloth Tape

Matte Cloth Tape -

Glass Cloth Tape

Glass Cloth Tape -

Red Polyester Tape

Red Polyester Tape -

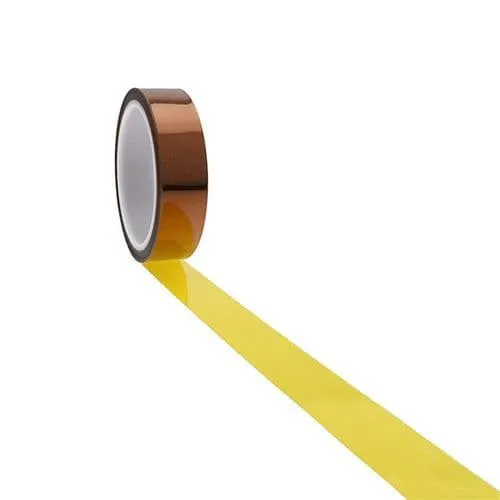

Amber Polyimide Tape

Amber Polyimide Tape -

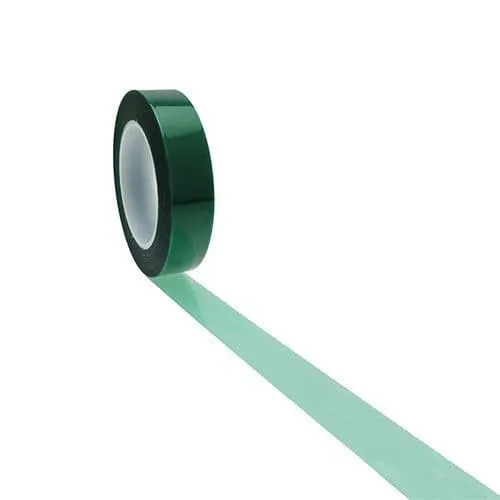

Green Polyester Tape

Green Polyester Tape -

Blue Polyester Tape

Blue Polyester Tape -

Anti Static Polyimide Tape

Anti Static Polyimide Tape

-

-

Panel Fasteners

-

School & Office Products

-

Rubber Seals

Business Services

Frequently Asked Questions

What materials do your anti vibration products use?

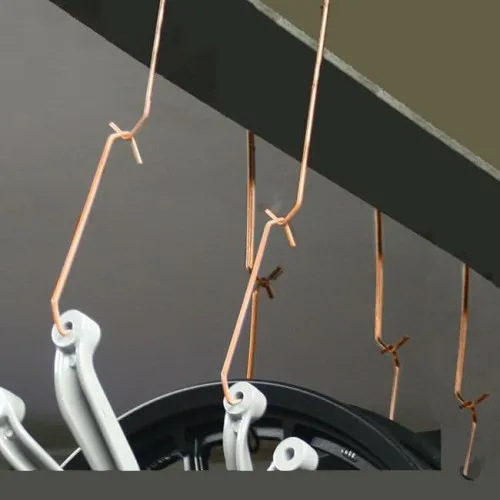

Our anti vibration buffers, anti vibration mounts and anti vibration turret mounts are constructed from high quality natural rubber. These are available in varying shore hardnesses to allow the user to select the appropriate stiffness for the load required by their application. Our anti vibration hanger mounts combine natural rubber with a zinc plated steel frame, offering durability at a great value price point.

What different types of anti vibration products are there?

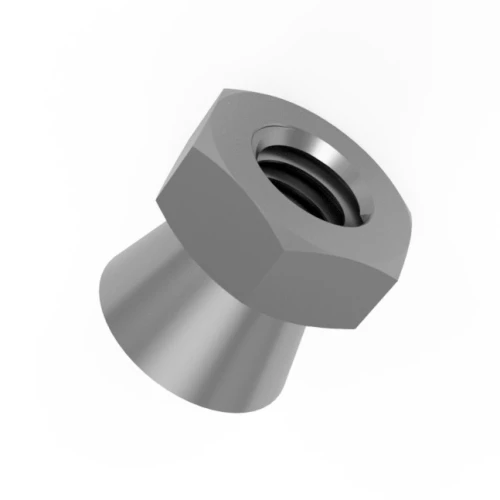

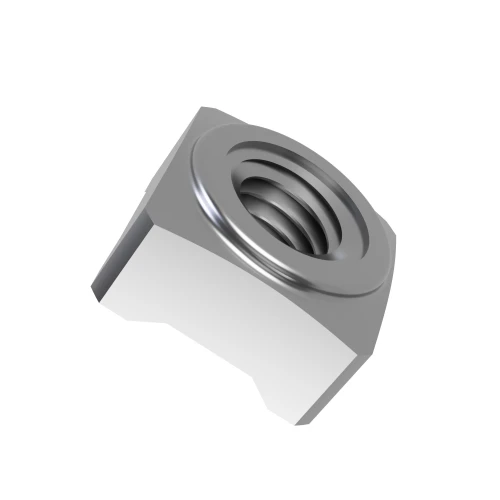

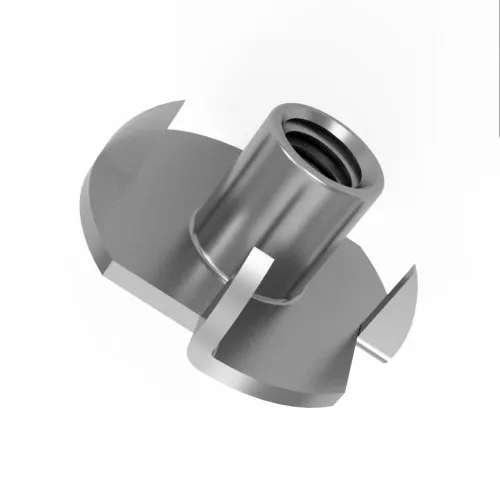

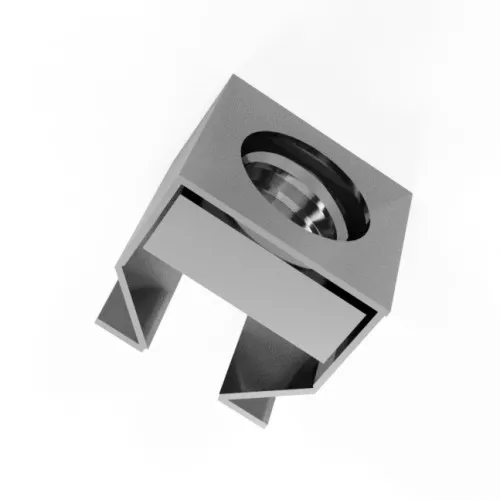

The most common products used to reduce vibration are buffers, mounts, turret mounts and hanger mounts. Within these product categories there are also different styles available. Anti vibration buffers come in flat, tapered or conical shapes and anti vibration mount styles differ depending on the type of threading required. E.g. Male to male, female to female or male to female. We also stock a selection of washers and anti vibration pads that may be suitable for reducing vibration in smaller and lighter objects.

What is the difference between anti vibration buffers and anti vibration mounts?

Generally speaking mounts have fixings on both ends and are used as joiners, whereas buffers only have a fixing on one end and the other side is used as a foot. As buffers are designed to be used as feet they will usually have a higher weight rating. However, it can be confusing because anti vibration mounts can also be used as feet for machinery. The crucial difference being that mounts have a threaded fixing on both sides, and a buffer only has one.

What are the benefits of using anti vibration buffers, mounts and hangers?

The advantage of using these products is that they are proven to reduce the vibrations generated by machinery and equipment. This is useful because it reduces operational noise. In many cases, it also increases the accuracy, efficiency and performance of the machine. Most crucially, reducing excess vibrations can increase the durability and therefore lifespan of the equipment. In industries that utilise large and expensive machinery this can translate to huge cost savings over time, resulting from reduced maintenance costs and downtime.

What is the maximum load capacity of an anti vibration buffer?

This can vary significantly and is generally determined by the size of the buffer and the shore hardness of the rubber that it is constructed from. All of our buffer products will have a "Weight Rating" attribute clearly defined on their product page. Please ensure that you select a buffer with a weight rating that is higher than the weight rating of the equipment that it will be supporting.

How do I install an anti vibration buffer?

To install simply screw your male threaded buffer into a female threaded fixing on the bottom of the machine, or screw a female buffer onto a male threaded fixing on the bottom of the machine. Just be sure to buy a buffer with the same thread size as the equipment it will be attached to. We supply anti vibration buffers that fit all of the most popular thread sizes, including: M3, M4, M5, M6, M8, M10, M12, M14 and M16.

What are anti vibration turret mounts?

Anti vibration turret mounts are a specialised form of anti vibration mount that are commonly attached to the base of air conditioning equipment and used as feet. They are used to reduce the vibrations caused during the operation of HVAC units and pumps, fans and air compressors. They have good deflection properties, which makes them effective at dispersing vibrations. We also supply a range of turret mount sizing to suit both light units and heavier units up to 500kg in weight.

What are these anti vibration products also known as?

Anti vibration buffers might also be known as rubber bump stops, rubber buffers or vibration dampers. Some customers also call anti vibration mounts - shock mounts, rubber bobbins or vibration damping. Anti vibration turret mounts could be described as vibration isolators for HVAC, air conditioning anti vibration mounts, or flanged rubber mounts. Finally, anti vibration hanger mounts are the same product as anti vibration ceiling hangers.

Which style of anti vibration product should I use?

We know it can be difficult to select the right anti vibration product for your project, so we've put together a guide to anti vibration product selection based on the load per mounting and deflection required. However, sometimes you might wonder if a buffer or a mount is the better choice for your project, or if a turret mount would work better than a buffer. If you have any questions please reach out to us, as we are happy to give technical advice. You can call us on 01233 713581, submit a question on our contact us page, or use the live chat in the bottom right corner of the website (during office hours).

Can Anti Vibration Mount Rubber Shore Hardness Be Customised for Specific Applications?

Yes, we can manufacture anti vibration mount rubber with customised shore hardness ratings to meet your exact application requirements. While our standard range covers most common applications with shore hardness options from soft (35 Shore A) to hard (70 Shore A), we understand that specialised equipment often demands precise vibration isolation characteristics. Our manufacturing capabilities allow us to produce anti vibration mount rubber in specific shore hardness values tailored to your load requirements, frequency isolation needs, and environmental conditions. Custom hardness formulations are particularly beneficial for unique applications such as marine engine mounting, precision instrumentation isolation, or extreme temperature environments where standard shore hardness options may not provide optimal performance. Contact our technical team to discuss your specific requirements and learn how customised shore hardness can enhance the effectiveness of your anti vibration mount rubber solution.

Can Anti Vibration Mount Rubber Shore Hardness Be Customised for Specific Applications?

Yes, we can manufacture anti vibration mount rubber with customised shore hardness ratings to meet your exact application requirements. While our standard range covers most common applications with shore hardness options from soft (35 Shore A) to hard (70 Shore A), we understand that specialised equipment often demands precise vibration isolation characteristics. Our manufacturing capabilities allow us to produce anti vibration mount rubber in specific shore hardness values tailored to your load requirements, frequency isolation needs, and environmental conditions. Custom hardness formulations are particularly beneficial for unique applications such as marine engine mounting, precision instrumentation isolation, or extreme temperature environments where standard shore hardness options may not provide optimal performance. Contact our technical team to discuss your specific requirements and learn how customised shore hardness can enhance the effectiveness of your anti vibration mount rubber solution.

Can Anti Vibration Mount Rubber Shore Hardness Be Customised for Specific Applications?

Yes, we can manufacture anti vibration mount rubber with customised shore hardness ratings to meet your exact application requirements. While our standard range covers most common applications with shore hardness options from soft (35 Shore A) to hard (70 Shore A), we understand that specialised equipment often demands precise vibration isolation characteristics. Our manufacturing capabilities allow us to produce anti vibration mount rubber in specific shore hardness values tailored to your load requirements, frequency isolation needs, and environmental conditions. Custom hardness formulations are particularly beneficial for unique applications such as marine engine mounting, precision instrumentation isolation, or extreme temperature environments where standard shore hardness options may not provide optimal performance. Contact our technical team to discuss your specific requirements and learn how customised shore hardness can enhance the effectiveness of your anti vibration mount rubber solution.

How fast can I get my order?

Need your parts tomorrow? Our rapid same day dispatch has got you covered! Simply place your order before 4pm Mon-Thurs or 2pm Friday and select our Next Day Delivery service in the shopping cart. We also offer Guaranteed AM delivery when required, in addition to a Saturday delivery option.

If you don't mind waiting, we have a Free delivery method for orders over £30, and an economic £4.85 2nd Class delivery for orders between £20-£30.

Can I get a Free Sample?

Free Samples can be requested through our product pages, displayed in the sizing table beside the product you require. Please note you can always give us a call on 01233 713 581 or contact us on Live Chat to discuss samples.

Do I need to Sign Up for an account?

You do not need to sign up to place an order, but it is recommended if you'd like to gain loyalty points, giving discount off future orders. To learn more about loyalty points, please view our rewards scheme page.

I am not sure what parts I need?

If you're unsure which part you need then please do not hesitate to give one of our friendly Sales Team a call on 01233 713 581 and they can assist you. Alternatively, we're active on Live Chat during office hours. You can open this using the button in the bottom right corner of the website. Alternatively, you can write to us using our contact form.

Do you offer Returns on Products?

We offer a return period on all of our products to give you peace of mind, to view our policies and learn more about this process should it be required, please see our returns policy page.

Can you supply different colours of this product?

In most cases we have the facilities to offer you different colours of a product, specific to your requirements. Minimum order quantities may apply depending on the manufacturing technique in question, but please get in touch with any queries you may have.

Is there a minimum order value?

Please note that there is a minimum order value of £10 through our website (inclusive of VAT).

If you're new to our website you may want to check out our frequently asked questions section for answers to common customer queries.

What do these abbrievations mean?

While browsing the website you may come across abbreviations used for material names that you are unfamiliar with. You can find an explanation for these in our material abbreviations guide.