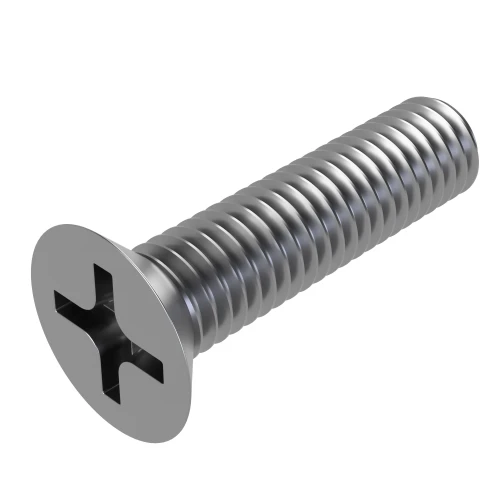

Countersunk Screws

Countersunk screws, also known as countersunk machine screws, are designed with a conical head that sits flush with the surface of the material once installed. This provides a smooth, low-profile finish that is ideal for woodworking, cabinetry, metal fabrication, electronics, machinery and general assembly tasks across the UK. Our range includes both durable nylon countersunk screws and high-performance stainless steel countersunk screws, catering to a wide variety of applications and industries.

What Are Countersunk Screws?

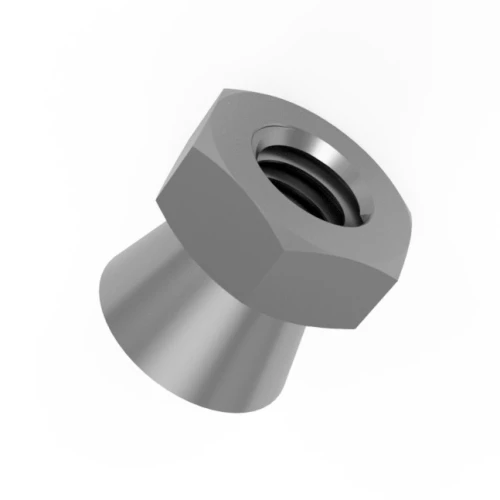

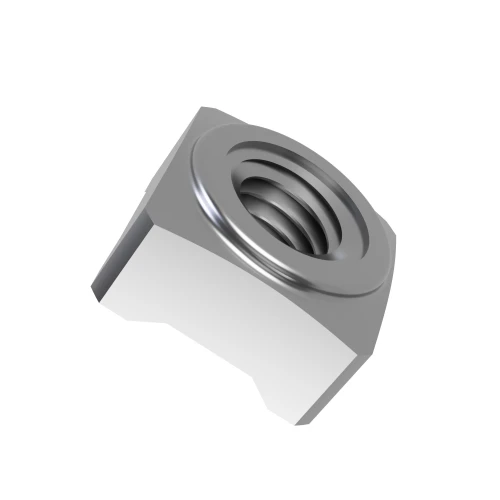

A countersunk screw features a tapered head designed to fit into a matching countersunk hole, allowing the top surface of the screw to sit level with or below the surrounding material. This design eliminates snag points, improves aesthetics and offers a professional finish. Countersunk screws are widely used in furniture production, electrical enclosures, machine components and applications where a flush fit is essential.

Product Range and Standards

We stock stainless steel countersunk screws in metric thread sizes from M3 to M24, offering excellent corrosion resistance and high strength for demanding or outdoor environments. Our nylon countersunk screws, manufactured to DIN 965, are available from M3 to M10 and are ideal for lightweight, non-conductive or corrosion-sensitive applications.

For engineered applications requiring specific standards, we offer popular variants including:

- DIN 7991 Torx Countersunk Screws – preferred for high torque control and reduced cam-out

- ISO 10642 Countersunk Hex Head Screws – widely used in machinery and mechanical assemblies

Why Choose Stainless Steel Countersunk Screws?

Our stainless steel countersunk screws provide exceptional corrosion resistance, strength and longevity. They are especially suitable for outdoor installations, marine environments, chemical exposure, and any application requiring a fastening that will not corrode over time.

Common UK Applications

- Furniture assembly, cabinetry and carpentry work requiring a flush finish

- Metal fabrication, sheet metal fixing and machine assembly

- Electronics, terminal housings and product casings

- Automotive and engineering applications where clean installation is important

- General purpose fastening using reliable stainless steel countersunk screws

If you require M10, M4, M5 or other popular sizes, we stock them as standard. For less common thread sizes or specialist variants, our team can often supply on request.

For assistance selecting the right countersunk screws for your project, please contact our experts on 01233 713581 for guidance on materials, thread sizes and standards.

Categories

-

Plugs & Stoppers

-

Tapered Rubber Plugs

Tapered Rubber Plugs -

Blanking Plugs

Blanking Plugs -

Ventilation Plugs

Ventilation Plugs -

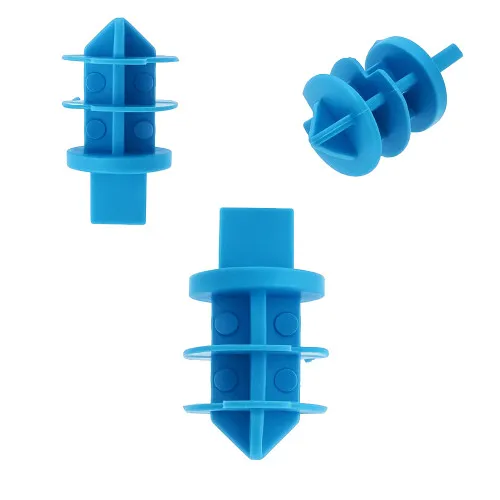

Fir Tree Plugs

Fir Tree Plugs -

Snap Fit Bushes

Snap Fit Bushes -

Liquid Tight Plugs

Liquid Tight Plugs -

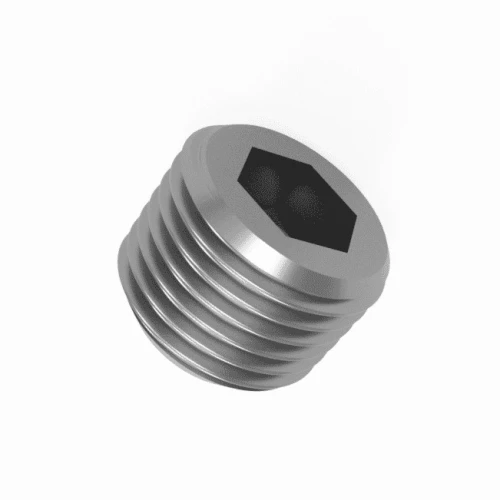

Threaded Plugs

Threaded Plugs -

Threaded Sealing Plugs

Threaded Sealing Plugs -

Reversible Tapered Plugs

Reversible Tapered Plugs -

Washer Masking Plugs

Washer Masking Plugs -

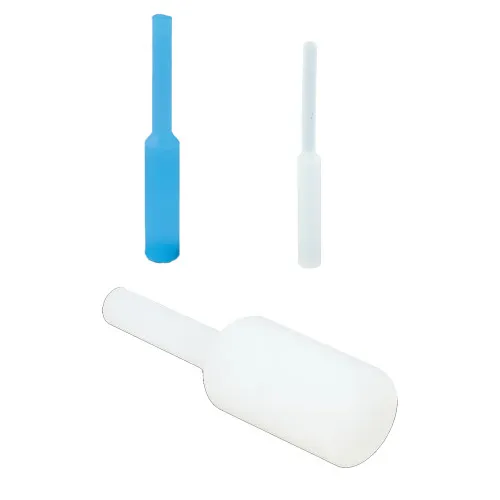

Silicone Tapered Plugs

Silicone Tapered Plugs -

Silicone Ribbed Plugs

Silicone Ribbed Plugs -

Silicone Plugs With Handle

Silicone Plugs With Handle -

Silicone Step Plugs

Silicone Step Plugs -

Silicone Pull Plugs

Silicone Pull Plugs -

Silicone Thread Masking Plugs

Silicone Thread Masking Plugs -

Barrel Plugs

Barrel Plugs -

Cylindrical Pull Tab Plugs

Cylindrical Pull Tab Plugs -

Finned Pull Tab Plugs

Finned Pull Tab Plugs -

Round Tube Plugs

Round Tube Plugs -

Snap Fit Hole Plugs

Snap Fit Hole Plugs -

Ribbed Pipe End Plugs

Ribbed Pipe End Plugs -

Door Stoppers

Door Stoppers -

Finned Hole Plugs

Finned Hole Plugs -

Silicone Double Flange Plugs

Silicone Double Flange Plugs -

Silicone Flange Plugs

Silicone Flange Plugs -

Silicone Washer Plugs

Silicone Washer Plugs -

Plastic End Plugs

Plastic End Plugs -

Stainless Steel Socket Pipe Plugs DIN 906

Stainless Steel Socket Pipe Plugs DIN 906

-

-

Furniture & Chair Feet

-

Adjustable Feet

-

Slotted Head Adjustable Feet

Slotted Head Adjustable Feet -

Rubber Adjustable Feet

Rubber Adjustable Feet -

Stainless Steel Adjustable Feet

Stainless Steel Adjustable Feet -

Ready To Install Sets

Ready To Install Sets -

One Piece Adjustable Feet

One Piece Adjustable Feet -

General Adjustable Feet

General Adjustable Feet -

Low Profile Adjustable Feet

Low Profile Adjustable Feet -

Machinery Mounting Feet

Machinery Mounting Feet -

Weight Rated Articulated Feet

Weight Rated Articulated Feet -

Heavy Duty Tilting Feet

Heavy Duty Tilting Feet -

Tilting Adjustable Feet

Tilting Adjustable Feet -

Metal Adjustable Feet

Metal Adjustable Feet -

Economic Adjustable Feet

Economic Adjustable Feet -

Allen Key Adjustable Feet

Allen Key Adjustable Feet -

Anti-Vibration Levelling Feet

Anti-Vibration Levelling Feet -

Balance Feet

Balance Feet -

Polyamide Adjustable Feet

Polyamide Adjustable Feet -

Pozi Base Adjustable Feet

Pozi Base Adjustable Feet -

Hexagon Base Feet

Hexagon Base Feet -

Threaded Fittings & Fixings

Threaded Fittings & Fixings

-

-

Cable Management

-

Cable Glands

Cable Glands -

Strain Relief

Strain Relief -

Rubber Grommets

Rubber Grommets -

Cable Ties

Cable Ties -

Blanking Plugs

Blanking Plugs -

Cable Clips

Cable Clips -

Cable Tie Mounts

Cable Tie Mounts -

Velcro Cable Management

Velcro Cable Management -

Aluminium Cable Clips

Aluminium Cable Clips -

Braided Cable Sleeving

Braided Cable Sleeving -

Multi Cable Clips

Multi Cable Clips -

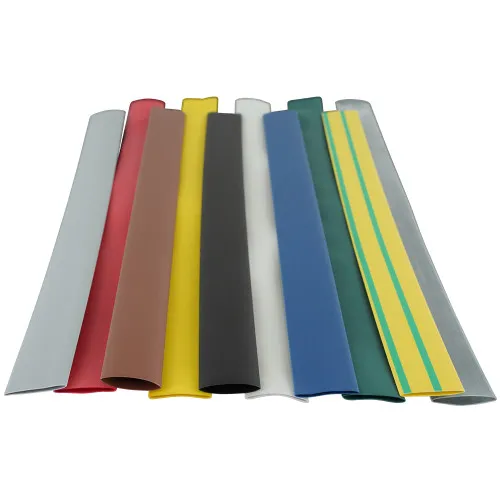

PVC Cable Sleeving

PVC Cable Sleeving -

Spiral Cable Wrap

Spiral Cable Wrap -

Heat Shrink Sleeves

Heat Shrink Sleeves -

Plastic Grommet Strips

Plastic Grommet Strips -

Adhesive Lined Heatshrink

Adhesive Lined Heatshrink -

Heat Shrink Caps

Heat Shrink Caps -

Nylon P Clips

Nylon P Clips -

Nylon P Clamps

Nylon P Clamps -

Rubber Grommet Strips

Rubber Grommet Strips -

Desk Cable Tidies

Desk Cable Tidies

-

-

Bolts and Screws

-

Hex Head Screws and Bolts

Hex Head Screws and Bolts -

Cap Screws

Cap Screws -

Countersunk Screws

Countersunk Screws -

Button Screws

Button Screws -

Pan Head Machine Screws

Pan Head Machine Screws -

Cheese Head Slotted Screws

Cheese Head Slotted Screws -

Security Fasteners

Security Fasteners -

Self Tapping Screws

Self Tapping Screws -

Wood Screws

Wood Screws -

Screws for Plastic

Screws for Plastic -

Knurled Fasteners

Knurled Fasteners -

Shoulder Bolts

Shoulder Bolts -

Grub Screws

Grub Screws -

Threaded Rod (All Thread)

Threaded Rod (All Thread) -

Weld Studs

Weld Studs -

Number Plate Screws

Number Plate Screws -

Nylon Screws & Bolts

Nylon Screws & Bolts -

Stainless Steel Bolts By Metric Thread Size

Stainless Steel Bolts By Metric Thread Size -

Small Bolts

Small Bolts -

Large Bolts

Large Bolts -

Industrial Hardware

Industrial Hardware

-

-

Washers

-

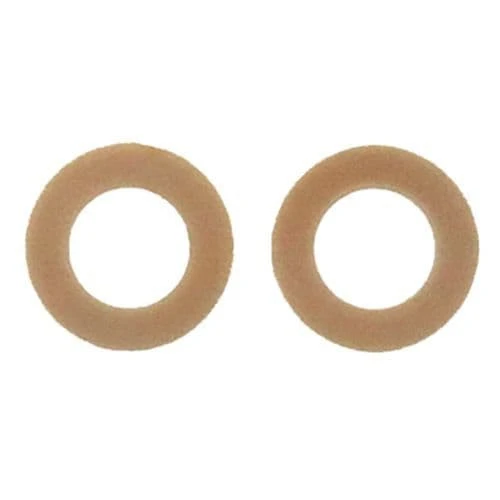

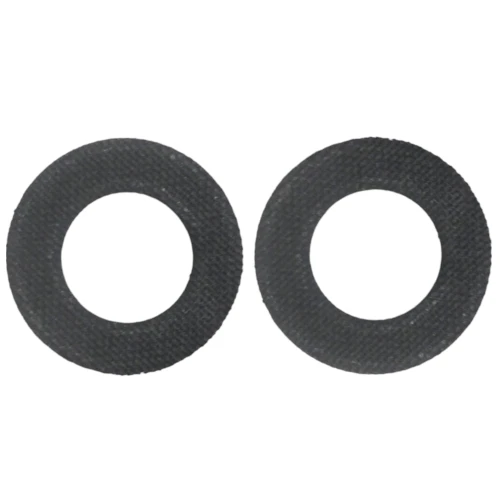

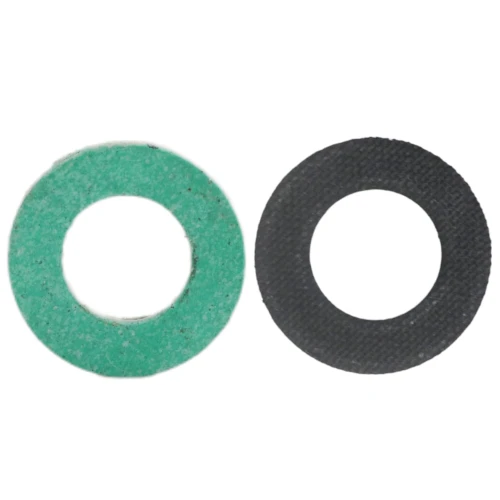

Rubber Washers

Rubber Washers -

Nylon Washers

Nylon Washers -

PTFE Washers

PTFE Washers -

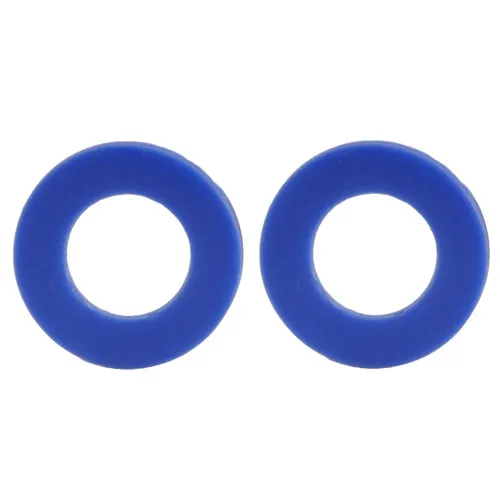

Silicone Washers

Silicone Washers -

Stainless Steel Flat Washers

Stainless Steel Flat Washers -

Stainless Steel Spring Washers

Stainless Steel Spring Washers -

Stainless Steel Curved Washers

Stainless Steel Curved Washers -

Stainless Steel Serrated Washers

Stainless Steel Serrated Washers -

Stainless Steel Tab Washers

Stainless Steel Tab Washers -

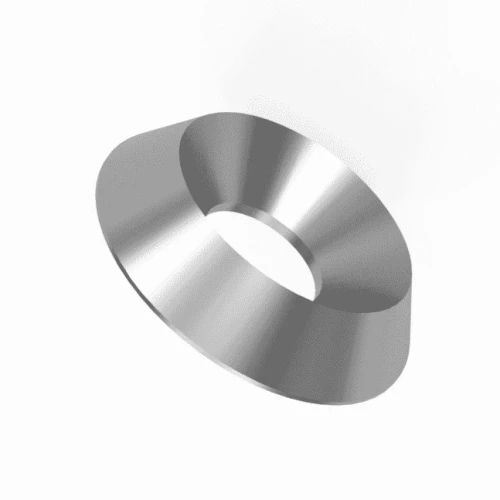

Stainless Steel Finishing Washers

Stainless Steel Finishing Washers -

Bonded Sealing Washers

Bonded Sealing Washers -

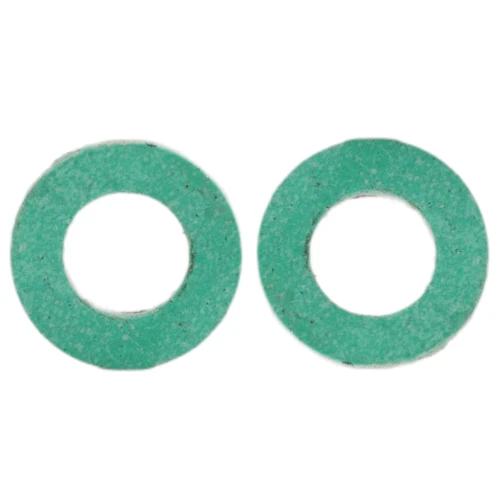

Red Fibre Washers

Red Fibre Washers -

Peek Washers

Peek Washers -

EPDM WRAS Washers

EPDM WRAS Washers -

Fibre WRAS Washers

Fibre WRAS Washers -

FKM Washers

FKM Washers -

WRAS Washers

WRAS Washers -

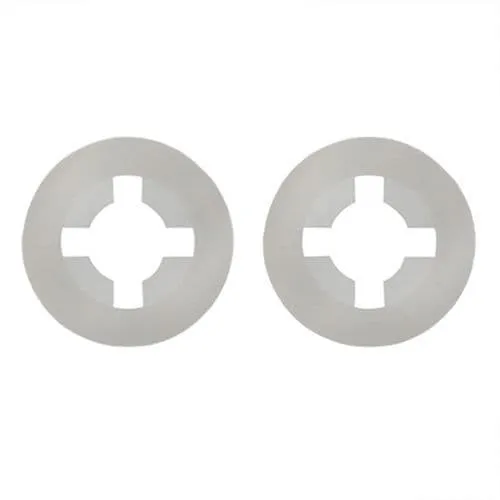

Anti-Loss Washers

Anti-Loss Washers -

Finishing Washers

Finishing Washers -

Headboard Washers

Headboard Washers -

Saddle Washers

Saddle Washers

-

-

Industrial Hardware

-

Hinges

Hinges -

Camlocks

Camlocks -

Latches

Latches -

Detent Pins

Detent Pins -

Index Plungers

Index Plungers -

Clamping Handles

Clamping Handles -

Bridge Handles

Bridge Handles -

Pull Handles

Pull Handles -

Threaded Handwheels

Threaded Handwheels -

Wing Screws & Knobs

Wing Screws & Knobs -

Knurled Thumbscrews

Knurled Thumbscrews -

Ball Knobs

Ball Knobs -

Control Handwheels

Control Handwheels -

Door Bolts

Door Bolts -

Adjustable Feet

Adjustable Feet -

Furniture Fixings

Furniture Fixings -

Plastic & Rubber Grips

Plastic & Rubber Grips -

Roof Support Systems

Roof Support Systems -

Push Fit Knobs

Push Fit Knobs -

Edging Strips

Edging Strips

-

-

Adhesive Tapes

-

PTFE Tape

PTFE Tape -

Packing Tape

Packing Tape -

Fragile Tape

Fragile Tape -

Cloth Tape

Cloth Tape -

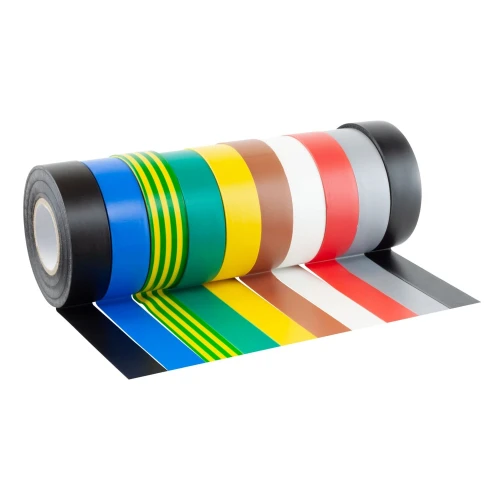

PVC Electrical Insulation Tape

PVC Electrical Insulation Tape -

Floor Marking Tape

Floor Marking Tape -

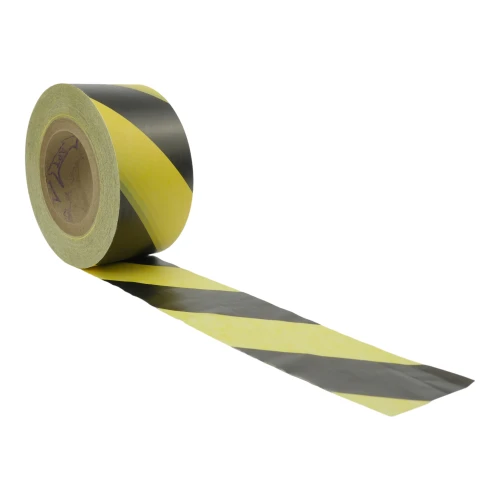

Safety Hazard Warning Tape

Safety Hazard Warning Tape -

Underground Cable Warning Tape

Underground Cable Warning Tape -

Non Slip Tape

Non Slip Tape -

Non-Adhesive Barrier Tape

Non-Adhesive Barrier Tape -

Double Sided Foam Tape

Double Sided Foam Tape -

UV Resistant Blue Masking Tape

UV Resistant Blue Masking Tape -

High Temp Crepe Tape

High Temp Crepe Tape -

Low Tack Paper Masking Tape

Low Tack Paper Masking Tape -

Aluminium Foil Tape

Aluminium Foil Tape -

Self Amalgamating PVC Tape

Self Amalgamating PVC Tape -

Self Amalgamating Silicone Tape

Self Amalgamating Silicone Tape -

Self Amalgamating EPR Tape

Self Amalgamating EPR Tape -

Fleece Tape

Fleece Tape -

Matte Cloth Tape

Matte Cloth Tape -

Glass Cloth Tape

Glass Cloth Tape -

Red Polyester Tape

Red Polyester Tape -

Amber Polyimide Tape

Amber Polyimide Tape -

Green Polyester Tape

Green Polyester Tape -

Blue Polyester Tape

Blue Polyester Tape -

Anti Static Polyimide Tape

Anti Static Polyimide Tape

-

-

Panel Fasteners

-

School & Office Products

-

Rubber Seals

Business Services

Frequently Asked Questions

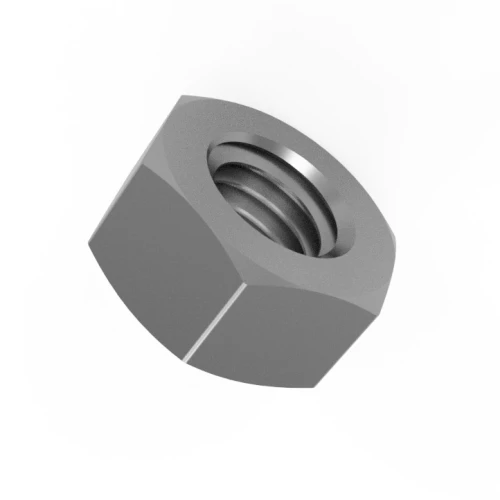

What is a countersunk screw?

Countersunk screws have been specifically designed to sit flush to the surface of the application that they are being fastened to. They feature a flat screw head, which has a sloping, conical bottom. This has been shaped to fit into the countersunk holes that must be drilled into the application's surface before installing the screw. Other common types of screws, such as the socket head screw or the button head screw would not fit flush to the surface that they are drilled into. This means that the screw head would stick out and not be flat against the object they were drilled into. Countersunk screw heads on the other hand, will sit flat against the drilled surface.

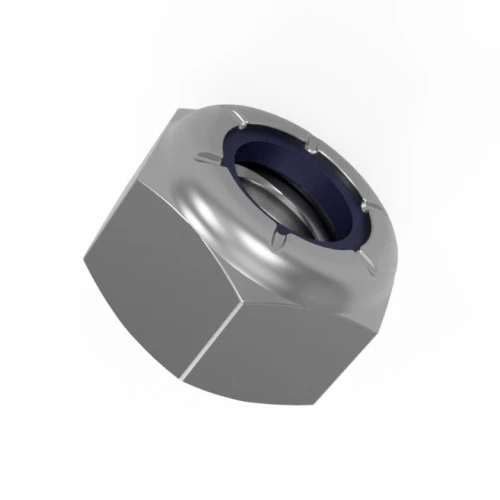

What types of stainless steel countersunk screws are there?

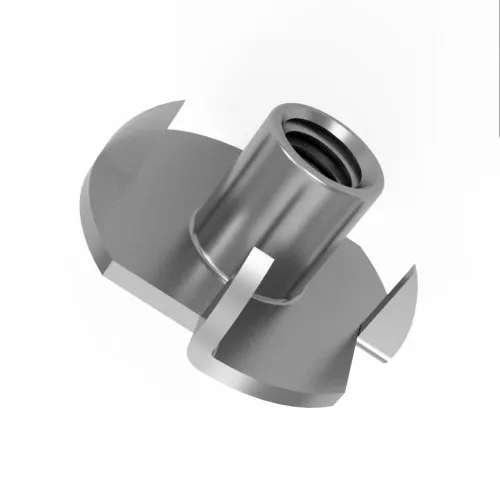

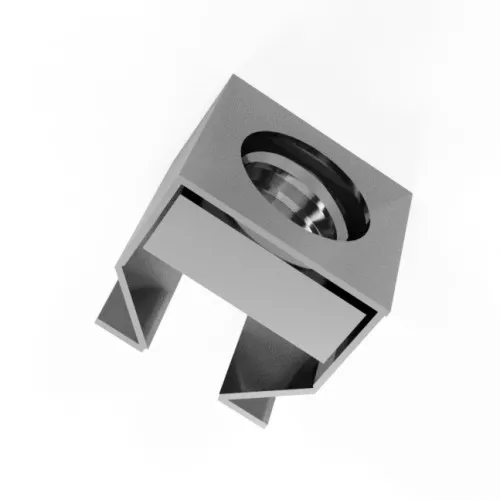

Stainless steel countersunk screws are often differentiated by the type of recess that is found on the screw head. As part of our standard catalogue, we sell five different styles of stainless steel countersunk screws. This includes countersunk hex screws, countersunk phillips screws and countersunk pin torx screws. We also offer stainless steel countersunk machine screws with a slot drive and countersunk machine screws with a torx recess. Machine screws have been designed for increased precision and mechanical strength and are generally better for fastening in metals or other hard materials. If you require a dimension or style of screw that isn't listed please get in touch, as we are often able to source additional requirements.

What are stainless steel countersunk screws also known as?

Stainless steel countersunk screws are often also described as stainless steel countersunk bolts. Many people will use the terms screws and bolts to describe the same fastening product. Additionally, customers will typically refer to them as simply, stainless countersunk screws or stainless countersunk bolts.

Do you sell m4 stainless steel countersunk bolts?

We are pleased to sell all of the commonly requested sizes of stainless steel countersunk bolts that customers find most useful for projects in the UK market. This includes the popular m5 stainless steel countersunk bolts. We also supply these in the commonly requested m5 x 70 and m5 x 60 thread lengths. In addition to this, we stock m4 stainless steel countersunk bolts and m6 stainless steel countersunk bolts, which are another customer favourite. Our range of metric thread sizes begins at m3 and increases at intervals up to m24. If you require a size or thread length that isn't shown, please contact us.

What are stainless steel countersunk bolts used for?

Stainless steel countersunk bolts are used primarily for their excellent resistance to corrosion and their ability to combine a secure fastening with a clean looking finish. Stainless steel countersunk screws are not a cheap fastening solution. However, the balance of durability, performance and clean aesthetics that they provide has led to them being used commonly across a wide range of industries and applications in the UK. You may see stainless countersunk bolts used in construction, to secure panels, cladding and roofing materials. Stainless countersunk screws are frequently used in woodwork, because they allow assembly of furniture, cabinets and other wooden pieces without any visible protrusions along the surface of the wood. Similarly, A4 marine grade countersunk screws are a popular fastening solution on boats and ships. Their ability to resist saltwater corrosion and simultaneously offer an aesthetic finish flush to the boat's surface is particularly valued on luxury vessels.

What are the standard dimensions of an M8 screw?

An M8 screw has a nominal major diameter of 8mm, which is the measurement across the outer edge of the threads. The standard coarse thread pitch for M8 screws is 1.25mm, meaning there's a 1.25mm distance between adjacent thread peaks. The minor diameter (core diameter) is approximately 6.647mm, whilst the pitch diameter sits at 7.188mm. When specifying M8 screws, the full designation appears as M8×1.25, though the pitch is often omitted when referring to standard coarse threads. These dimensions conform to ISO 262 metric thread standards, ensuring compatibility across different manufacturers and applications.

What are the advantages of stainless steel countersunk screws?

Stainless steel countersunk screws provide excellent corrosion resistance, making them ideal for outdoor, marine, chemical and high-moisture environments. Their flush-fit head design offers a clean aesthetic while maintaining strong mechanical performance. This combination makes stainless steel countersunk screws a preferred choice for long-lasting, professional-grade installations.

When should I use stainless steel countersunk screws instead of nylon or zinc-plated options?

Stainless steel countersunk screws should be used when strength, durability and corrosion resistance are essential. They outperform nylon and zinc-plated screws in demanding environments such as construction, metalwork, automotive engineering and outdoor applications. If the installation may encounter moisture or requires long-term stability, stainless steel is the most reliable choice.

How fast can I get my order?

Need your parts tomorrow? Our rapid same day dispatch has got you covered! Simply place your order before 4pm Mon-Thurs or 2pm Friday and select our Next Day Delivery service in the shopping cart. We also offer Guaranteed AM delivery when required, in addition to a Saturday delivery option.

If you don't mind waiting, we have a Free delivery method for orders over £30, and an economic £4.85 2nd Class delivery for orders between £20-£30.

Can I get a Free Sample?

Free Samples can be requested through our product pages, displayed in the sizing table beside the product you require. Please note you can always give us a call on 01233 713 581 or contact us on Live Chat to discuss samples.

Do I need to Sign Up for an account?

You do not need to sign up to place an order, but it is recommended if you'd like to gain loyalty points, giving discount off future orders. To learn more about loyalty points, please view our rewards scheme page.

I am not sure what parts I need?

If you're unsure which part you need then please do not hesitate to give one of our friendly Sales Team a call on 01233 713 581 and they can assist you. Alternatively, we're active on Live Chat during office hours. You can open this using the button in the bottom right corner of the website. Alternatively, you can write to us using our contact form.

Do you offer Returns on Products?

We offer a return period on all of our products to give you peace of mind, to view our policies and learn more about this process should it be required, please see our returns policy page.

Can you supply different colours of this product?

In most cases we have the facilities to offer you different colours of a product, specific to your requirements. Minimum order quantities may apply depending on the manufacturing technique in question, but please get in touch with any queries you may have.

Is there a minimum order value?

Please note that there is a minimum order value of £10 through our website (inclusive of VAT).

If you're new to our website you may want to check out our frequently asked questions section for answers to common customer queries.

What do these abbrievations mean?

While browsing the website you may come across abbreviations used for material names that you are unfamiliar with. You can find an explanation for these in our material abbreviations guide.