Silicone Caps

Our extensive range of silicone caps, including silicone end caps, silicone rubber end caps and silicone masking caps, are manufactured from premium quality silicone rubber compounds designed to withstand extreme temperatures between -40°C and 315°C. These plastic end caps serve as essential masking solutions across numerous UK industries including powder coating, anodising, shot blasting, automotive refinishing, aerospace manufacturing, medical device production and electronics assembly. The primary benefit of our silicone caps lies in their exceptional temperature resistance, chemical inertness and reusability, making them significantly more cost-effective than single-use alternatives whilst providing superior protection during high-temperature industrial processes.

These silicone caps are available in multiple configurations including round silicone end caps, tapered silicone cone caps, silicone washer caps, silicone rectangular covers and easy-fit masking caps/ powder coating caps, our silicone cap range accommodates internal diameters from 1mm to over 47mm. The naturally flexible and durable properties of silicone rubber allow these caps to conform to irregular shapes and provide secure sealing whilst maintaining their integrity through multiple use cycles. Unlike EPDM alternatives, our silicone caps excel in higher temperature applications where exposure to alkalis and acids is minimal, offering superior longevity and performance reliability in demanding industrial environments.

Available Materials and Style Options:

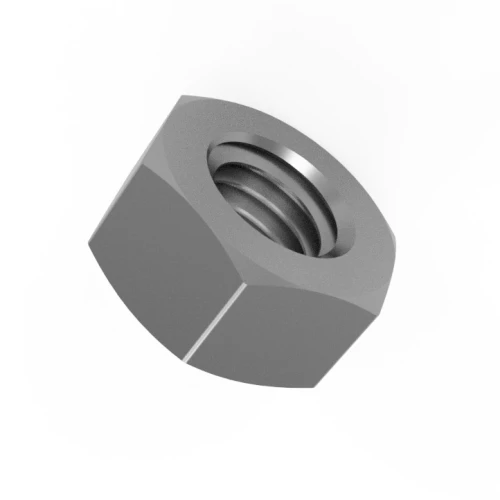

- Round silicone end caps - Standard cylindrical design for tubes, pipes and threaded studs

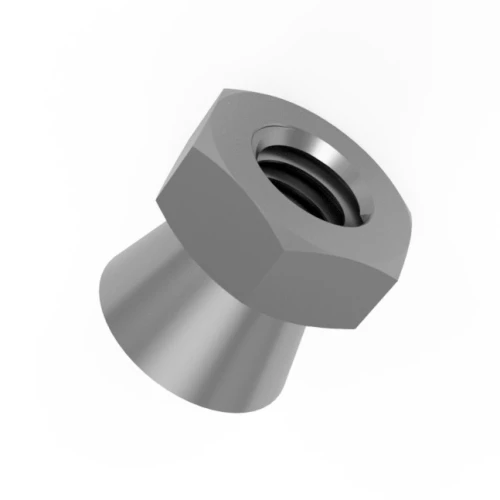

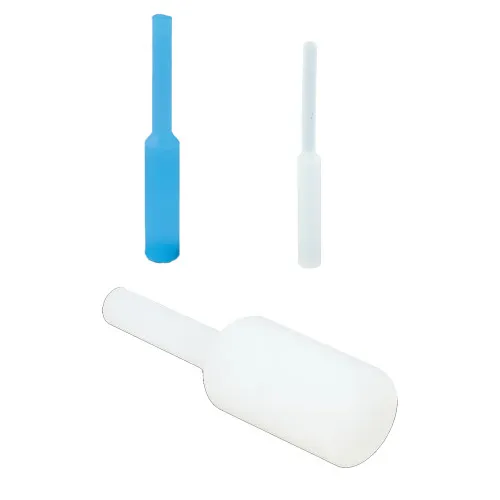

- Silicone cone caps with tapered interior - Accommodates multiple diameters with secure fit

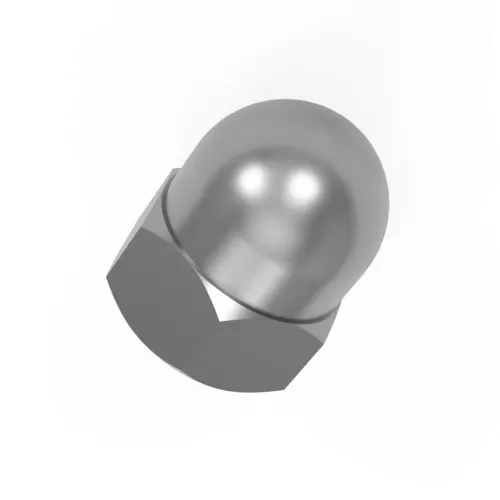

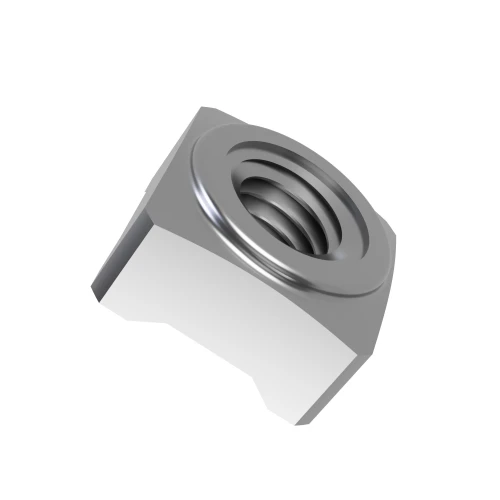

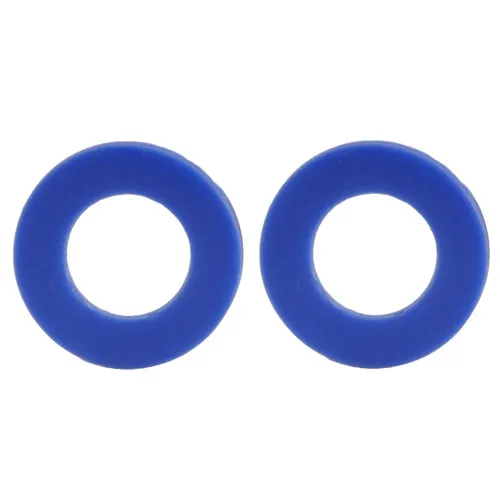

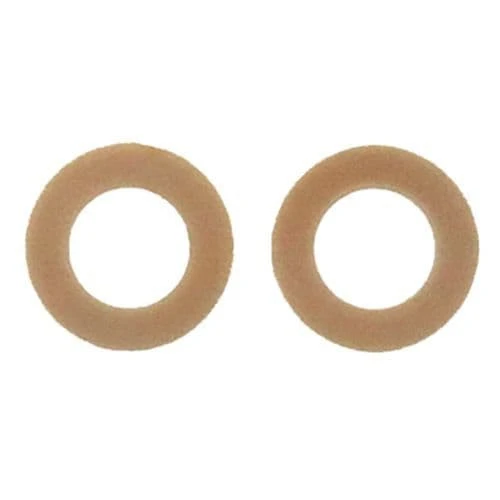

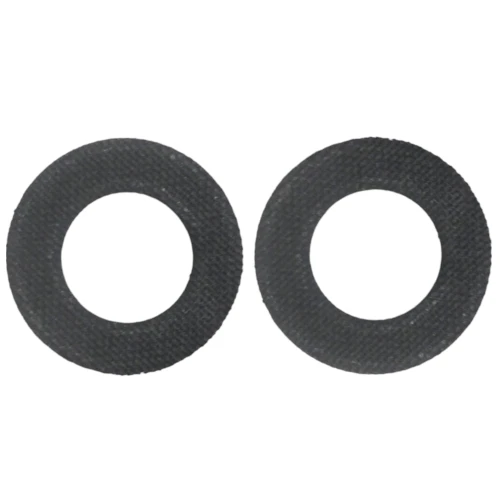

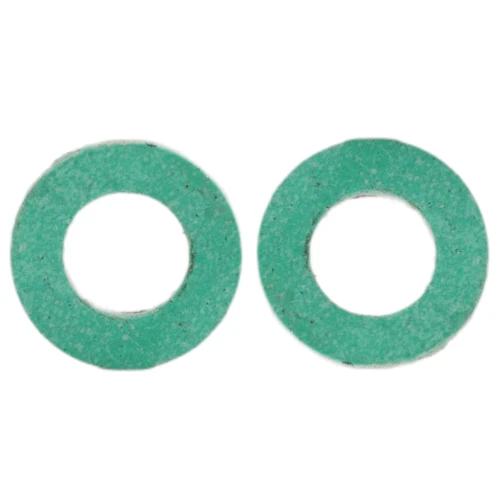

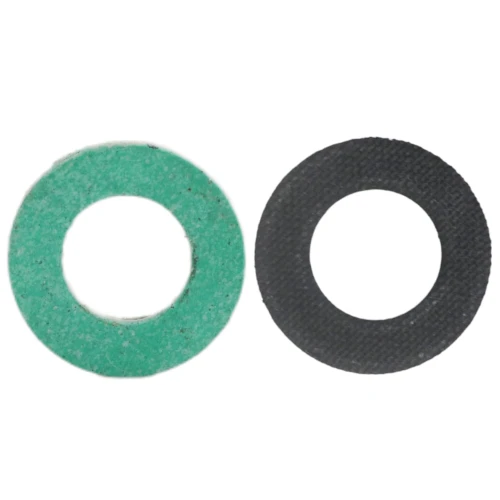

- Silicone washer caps - Low-profile design for flat surface applications

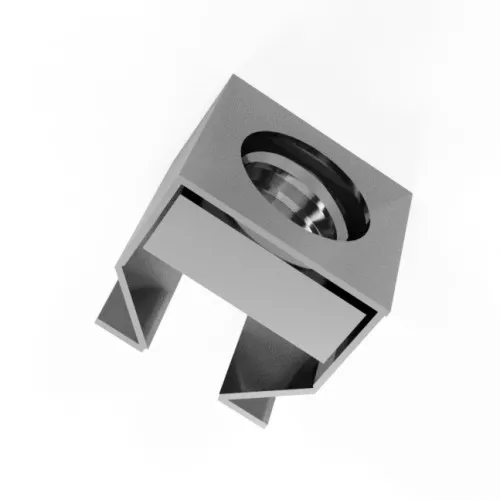

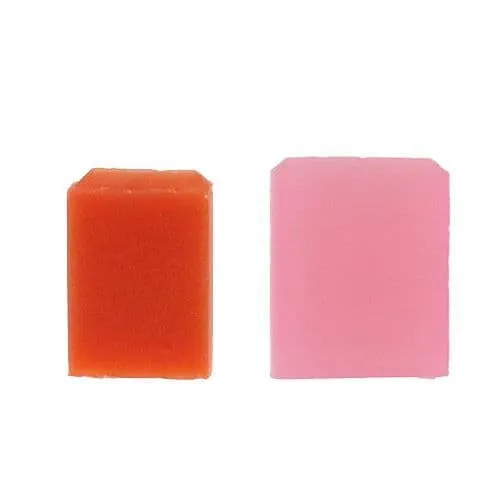

- Silicone rectangular covers - Specialised protection for square and rectangular components

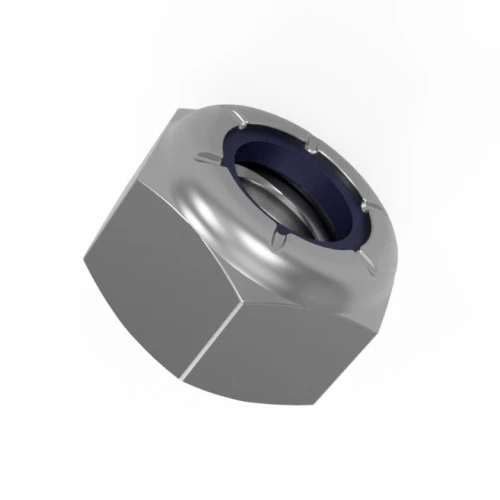

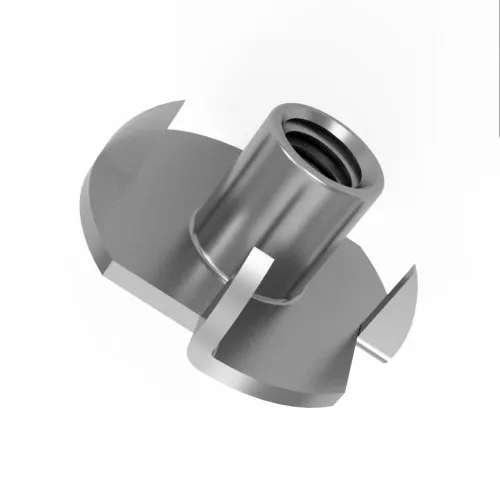

- Easy-fit masking caps (Eze-caps) - Flanged design with ribbed shaft for quick application and removal

- Standard silicone formulation - Temperature range -40°C to 315°C

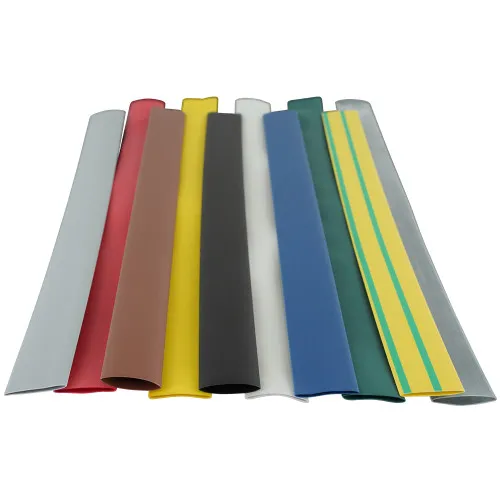

- Multiple colour options available including black, clear, blue, red and custom colours on request

- Size range from 1mm to 47mm internal diameter with custom sizing available

Key Features and Benefits:

- Exceptional high-temperature resistance up to 315°C, ideal for powder coating ovens and industrial baking processes

- Chemical resistance to most solvents, oils and industrial chemicals commonly used in UK manufacturing

- Reusable design reduces operational costs and environmental impact compared to disposable masking solutions

- Flexible silicone material conforms to irregular shapes and provides excellent sealing properties

- Quick and easy application with secure retention during processing and simple removal whilst components remain hot

- Non-marking surface prevents contamination of finished parts and maintains part quality standards

- Colour-coding options enable size identification and process organisation in high-volume production environments

- Durable construction withstands repeated use cycles, reducing replacement frequency and inventory costs

- Compatible with both threaded and non-threaded applications for maximum versatility

Common UK Use Cases:

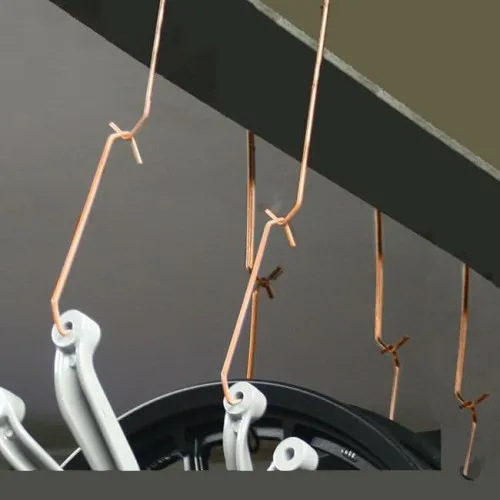

- Powder coating facilities protecting threaded holes, studs and sensitive areas during electrostatic coating and curing processes up to 200°C

- Automotive and aerospace component finishing, masking precision-machined surfaces during anodising and hard coat treatments

- Medical device manufacturing protecting sterile surfaces and threaded connections during cleaning, sterilisation and coating applications

- Electronics and telecommunications equipment production, masking connector pins and sensitive components during conformal coating processes

- General engineering and fabrication shops protecting machined threads and finished surfaces during shot blasting, priming and painting operations

Related Vital Parts Products:

- Complete masking caps range - Alternative high-temperature masking solutions including EPDM and vinyl options

- Tapered caps - Complementary masking solutions for holes and cavities

- High-temperature masking tapes - Complete masking system solutions for complex geometries

- EPDM caps - Cost-effective alternative with superior chemical resistance for lower temperature applications

For technical applications requiring specific certifications such as automotive OEM standards, aerospace specifications, or medical device regulations, please contact our technical team for guidance on the most suitable silicone compound and cap design for your specific requirements.

Professional installation guidance is available through our comprehensive Guide to End Caps, which provides detailed instructions for optimal cap selection, application techniques and maintenance procedures to maximise component life and masking effectiveness.

Call Vital Parts:

For quick quotes, same-day dispatch, custom sizes, or bulk discounts, call our sales line on 01233 713 581. Businesses can register for a Vital Parts Business Account to benefit from priority shipping, trade pricing, free product samples, credit accounts and a dedicated account manager to support your ongoing silicone cap requirements and provide technical expertise for complex masking applications.

Categories

-

Plugs & Stoppers

-

Tapered Rubber Plugs

Tapered Rubber Plugs -

Blanking Plugs

Blanking Plugs -

Ventilation Plugs

Ventilation Plugs -

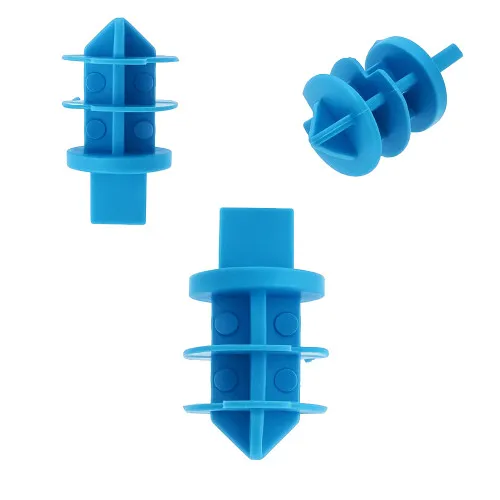

Fir Tree Plugs

Fir Tree Plugs -

Snap Fit Bushes

Snap Fit Bushes -

Liquid Tight Plugs

Liquid Tight Plugs -

Threaded Plugs

Threaded Plugs -

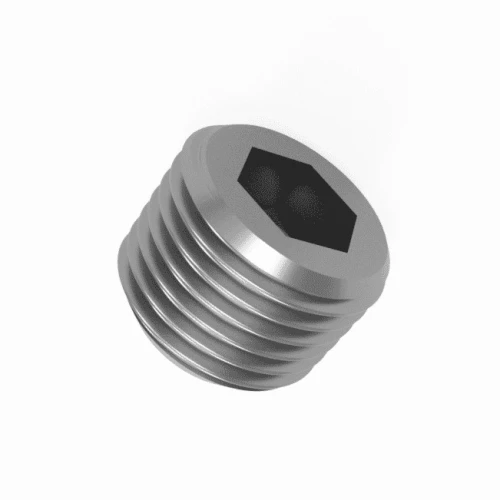

Threaded Sealing Plugs

Threaded Sealing Plugs -

Reversible Tapered Plugs

Reversible Tapered Plugs -

Washer Masking Plugs

Washer Masking Plugs -

Silicone Tapered Plugs

Silicone Tapered Plugs -

Silicone Ribbed Plugs

Silicone Ribbed Plugs -

Silicone Plugs With Handle

Silicone Plugs With Handle -

Silicone Step Plugs

Silicone Step Plugs -

Silicone Pull Plugs

Silicone Pull Plugs -

Silicone Thread Masking Plugs

Silicone Thread Masking Plugs -

Barrel Plugs

Barrel Plugs -

Cylindrical Pull Tab Plugs

Cylindrical Pull Tab Plugs -

Finned Pull Tab Plugs

Finned Pull Tab Plugs -

Round Tube Plugs

Round Tube Plugs -

Snap Fit Hole Plugs

Snap Fit Hole Plugs -

Ribbed Pipe End Plugs

Ribbed Pipe End Plugs -

Door Stoppers

Door Stoppers -

Finned Hole Plugs

Finned Hole Plugs -

Silicone Double Flange Plugs

Silicone Double Flange Plugs -

Silicone Flange Plugs

Silicone Flange Plugs -

Silicone Washer Plugs

Silicone Washer Plugs -

Plastic End Plugs

Plastic End Plugs -

Stainless Steel Socket Pipe Plugs DIN 906

Stainless Steel Socket Pipe Plugs DIN 906

-

-

Furniture & Chair Feet

-

Adjustable Feet

-

Slotted Head Adjustable Feet

Slotted Head Adjustable Feet -

Rubber Adjustable Feet

Rubber Adjustable Feet -

Stainless Steel Adjustable Feet

Stainless Steel Adjustable Feet -

Ready To Install Sets

Ready To Install Sets -

One Piece Adjustable Feet

One Piece Adjustable Feet -

General Adjustable Feet

General Adjustable Feet -

Low Profile Adjustable Feet

Low Profile Adjustable Feet -

Machinery Mounting Feet

Machinery Mounting Feet -

Weight Rated Articulated Feet

Weight Rated Articulated Feet -

Heavy Duty Tilting Feet

Heavy Duty Tilting Feet -

Tilting Adjustable Feet

Tilting Adjustable Feet -

Metal Adjustable Feet

Metal Adjustable Feet -

Economic Adjustable Feet

Economic Adjustable Feet -

Allen Key Adjustable Feet

Allen Key Adjustable Feet -

Anti-Vibration Levelling Feet

Anti-Vibration Levelling Feet -

Balance Feet

Balance Feet -

Polyamide Adjustable Feet

Polyamide Adjustable Feet -

Pozi Base Adjustable Feet

Pozi Base Adjustable Feet -

Hexagon Base Feet

Hexagon Base Feet -

Threaded Fittings & Fixings

Threaded Fittings & Fixings

-

-

Cable Management

-

Cable Glands

Cable Glands -

Strain Relief

Strain Relief -

Rubber Grommets

Rubber Grommets -

Cable Ties

Cable Ties -

Blanking Plugs

Blanking Plugs -

Cable Clips

Cable Clips -

Cable Tie Mounts

Cable Tie Mounts -

Velcro Cable Management

Velcro Cable Management -

Aluminium Cable Clips

Aluminium Cable Clips -

Braided Cable Sleeving

Braided Cable Sleeving -

Multi Cable Clips

Multi Cable Clips -

PVC Cable Sleeving

PVC Cable Sleeving -

Spiral Cable Wrap

Spiral Cable Wrap -

Heat Shrink Sleeves

Heat Shrink Sleeves -

Plastic Grommet Strips

Plastic Grommet Strips -

Adhesive Lined Heatshrink

Adhesive Lined Heatshrink -

Heat Shrink Caps

Heat Shrink Caps -

Nylon P Clips

Nylon P Clips -

Nylon P Clamps

Nylon P Clamps -

Rubber Grommet Strips

Rubber Grommet Strips -

Desk Cable Tidies

Desk Cable Tidies

-

-

Bolts and Screws

-

Hex Head Screws and Bolts

Hex Head Screws and Bolts -

Cap Screws

Cap Screws -

Countersunk Screws

Countersunk Screws -

Button Screws

Button Screws -

Pan Head Machine Screws

Pan Head Machine Screws -

Cheese Head Slotted Screws

Cheese Head Slotted Screws -

Security Fasteners

Security Fasteners -

Self Tapping Screws

Self Tapping Screws -

Wood Screws

Wood Screws -

Screws for Plastic

Screws for Plastic -

Knurled Fasteners

Knurled Fasteners -

Shoulder Bolts

Shoulder Bolts -

Grub Screws

Grub Screws -

Threaded Rod (All Thread)

Threaded Rod (All Thread) -

Weld Studs

Weld Studs -

Number Plate Screws

Number Plate Screws -

Nylon Screws & Bolts

Nylon Screws & Bolts -

Stainless Steel Bolts By Metric Thread Size

Stainless Steel Bolts By Metric Thread Size -

Small Bolts

Small Bolts -

Large Bolts

Large Bolts -

Industrial Hardware

Industrial Hardware

-

-

Washers

-

Rubber Washers

Rubber Washers -

Nylon Washers

Nylon Washers -

PTFE Washers

PTFE Washers -

Silicone Washers

Silicone Washers -

Stainless Steel Flat Washers

Stainless Steel Flat Washers -

Stainless Steel Spring Washers

Stainless Steel Spring Washers -

Stainless Steel Curved Washers

Stainless Steel Curved Washers -

Stainless Steel Serrated Washers

Stainless Steel Serrated Washers -

Stainless Steel Tab Washers

Stainless Steel Tab Washers -

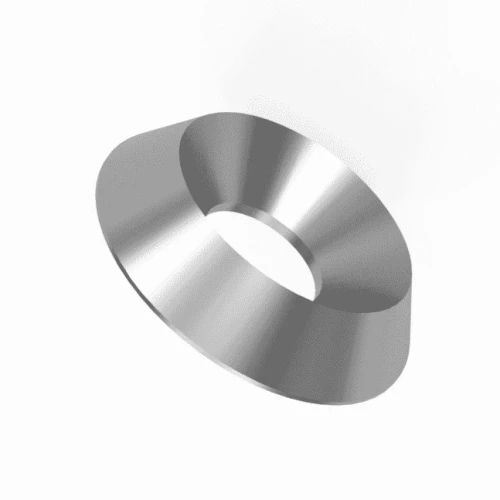

Stainless Steel Finishing Washers

Stainless Steel Finishing Washers -

Bonded Sealing Washers

Bonded Sealing Washers -

Red Fibre Washers

Red Fibre Washers -

Peek Washers

Peek Washers -

EPDM WRAS Washers

EPDM WRAS Washers -

Fibre WRAS Washers

Fibre WRAS Washers -

FKM Washers

FKM Washers -

WRAS Washers

WRAS Washers -

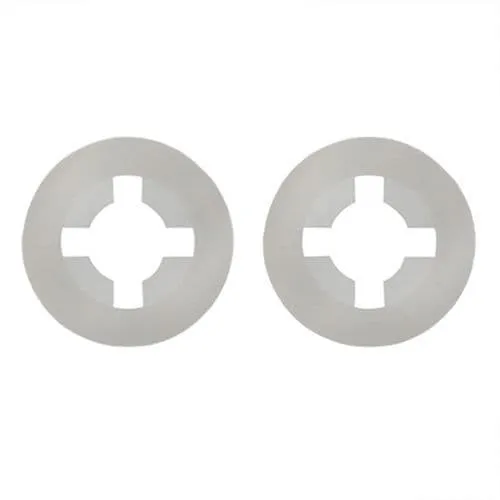

Anti-Loss Washers

Anti-Loss Washers -

Finishing Washers

Finishing Washers -

Headboard Washers

Headboard Washers -

Saddle Washers

Saddle Washers

-

-

Industrial Hardware

-

Hinges

Hinges -

Camlocks

Camlocks -

Latches

Latches -

Detent Pins

Detent Pins -

Index Plungers

Index Plungers -

Clamping Handles

Clamping Handles -

Bridge Handles

Bridge Handles -

Pull Handles

Pull Handles -

Threaded Handwheels

Threaded Handwheels -

Wing Screws & Knobs

Wing Screws & Knobs -

Knurled Thumbscrews

Knurled Thumbscrews -

Ball Knobs

Ball Knobs -

Control Handwheels

Control Handwheels -

Door Bolts

Door Bolts -

Adjustable Feet

Adjustable Feet -

Furniture Fixings

Furniture Fixings -

Plastic & Rubber Grips

Plastic & Rubber Grips -

Roof Support Systems

Roof Support Systems -

Push Fit Knobs

Push Fit Knobs -

Edging Strips

Edging Strips

-

-

Adhesive Tapes

-

PTFE Tape

PTFE Tape -

Packing Tape

Packing Tape -

Fragile Tape

Fragile Tape -

Cloth Tape

Cloth Tape -

PVC Electrical Insulation Tape

PVC Electrical Insulation Tape -

Floor Marking Tape

Floor Marking Tape -

Safety Hazard Warning Tape

Safety Hazard Warning Tape -

Underground Cable Warning Tape

Underground Cable Warning Tape -

Non Slip Tape

Non Slip Tape -

Non-Adhesive Barrier Tape

Non-Adhesive Barrier Tape -

Double Sided Foam Tape

Double Sided Foam Tape -

UV Resistant Blue Masking Tape

UV Resistant Blue Masking Tape -

High Temp Crepe Tape

High Temp Crepe Tape -

Low Tack Paper Masking Tape

Low Tack Paper Masking Tape -

Aluminium Foil Tape

Aluminium Foil Tape -

Self Amalgamating PVC Tape

Self Amalgamating PVC Tape -

Self Amalgamating Silicone Tape

Self Amalgamating Silicone Tape -

Self Amalgamating EPR Tape

Self Amalgamating EPR Tape -

Fleece Tape

Fleece Tape -

Matte Cloth Tape

Matte Cloth Tape -

Glass Cloth Tape

Glass Cloth Tape -

Red Polyester Tape

Red Polyester Tape -

Amber Polyimide Tape

Amber Polyimide Tape -

Green Polyester Tape

Green Polyester Tape -

Blue Polyester Tape

Blue Polyester Tape -

Anti Static Polyimide Tape

Anti Static Polyimide Tape

-

-

Panel Fasteners

-

School & Office Products

-

Rubber Seals

Business Services

Frequently Asked Questions

What grade of Silicone do you use?

Our Silicone Caps are manufactured from a 40-80sh grade of Silicone, with varying shore hardnesses of 35-85 capable of resisting temperatures between -40 to +350°C.

Are your products manufactured to ISO standards?

Yes, our Silicone Caps produced in line with ISO9001:2000 Manufacturing standards to give you confidence in the quality of product that we supply.

Can I get a Data Sheet for an individual size?

Yes we are able to provide a Data Sheet for each and every size available through our website. You can request one by getting in touch with us using our contact form, or by speaking over Live Chat.

What are silicone caps and what are they used for?

Silicone caps are high-temperature resistant protective covers made from premium silicone rubber. They're primarily used for masking applications during powder coating, anodising, shot blasting, e-coating, plating, and painting processes. These caps protect threaded and non-threaded studs, bolts, tube ends, and holes from coating overspray while withstanding extreme temperatures up to 350°C.

Which industries use high-temperature silicone caps?

Our high-temperature silicone caps are used across a variety of sectors, including:

• Powder coating and metal finishing

• Automotive manufacturing and maintenance

• Aerospace and defence

• Electronics and electrical assembly

• General engineering and fabrication

• Silicone caps are chosen where heat resistance, flexibility, and a secure fit are essential.

What temperature can silicone caps withstand?

Our high-temperature silicone caps can withstand temperatures between -40°C and 350°C (depending on the type chosen). This makes them ideal for powder coating ovens, anodising processes, and other high-temperature applications where standard materials would melt or degrade.

What sizes and styles of silicone caps do you supply?

We stock a wide range of silicone caps to suit different applications, including:

• Standard round silicone caps in a variety of internal diameters and lengths

• High-temperature masking caps for use during finishing

• Tapered and cone-shaped caps for a snug fit on irregular shapes

• Flat and flanged end caps for specialised protection

Our range covers popular metric sizes and bulk pack options for commercial use.

How do silicone caps aid in powder coating and plating?

Silicone caps are ideal for use as masking products during powder coating, electroplating, and painting processes:

• They protect threads, studs, and fittings from unwanted coating or contamination

• The flexible, heat-resistant material allows repeated use through multiple cycles

• Easy push-fit design makes installation and removal quick and efficient

• Prevents costly rework by ensuring clean, coated-free threads and holes

How do I choose the right cap size and type?

To select the correct silicone cap for your needs:

• Measure the outside diameter of the part to be capped

• Choose a cap with an internal diameter slightly smaller than the component for a secure fit

• Consider the application temperature and chemical exposure

• Select the cap length and shape (standard, tapered, flat, or flanged) based on your protection requirements

If you need assistance selecting the right size or would like to discuss custom options, contact our expert team on 01233 713581.

Are silicone caps reusable?

Yes, silicone caps are designed to be reusable multiple times. The premium silicone material maintains its flexibility and doesn't harden, crack, or become brittle after exposure to high temperatures. Simply remove any coating residue by flexing the cap, and it's ready for reuse.

How do I choose the right size silicone cap?

When selecting a silicone cap, the inside diameter (ID) should be 2-5% smaller than the diameter of the stud or bolt you're masking. For optimal fit, choose a cap length that's slightly longer than the masking area. If the cap ID is less than 5% of the stud diameter, ensure you select a longer cap for easier removal.

What's the difference between silicone caps and vinyl caps?

Silicone caps offer superior temperature resistance (often beyond 350°C) compared to vinyl caps (up to 170°C). While vinyl caps are more economical, silicone caps provide better flexibility, chemical resistance, and durability for demanding applications like powder coating and anodising.

What are silicone cone caps and when should I use them?

Silicone cone caps feature a tapered design that allows them to fit over a range of diameters, making them more versatile than standard caps. They're ideal when you have varying stud or hole sizes during the masking process. The conical shape provides flexibility for masking threaded studs, rods, bolts, or tube ends where exact sizing isn't critical.

Can silicone cone caps be used as both caps and plugs?

Yes, silicone cone caps are dual-purpose. Their tapered design allows them to function as caps over external features like studs and bolts, or as plugs when inverted to seal holes. This versatility makes them an efficient choice for busy production lines where multiple masking solutions are needed.

What makes silicone washer caps different from standard caps?

Silicone washer caps feature an integrated washer or flange at the base that creates a grounding area around the masked stud or hole. This eliminates the need for two-stage masking and provides both masking and grounding protection in one product, making them particularly useful for powder coating applications.

Do washer caps work for both threaded and non-threaded applications?

Yes, silicone washer caps are designed to work on both threaded and non-threaded studs and holes. The flexible silicone material conforms to irregular shapes and provides an effective seal regardless of the surface finish.

What are silicone rectangular covers used for?

Silicone rectangular covers are specifically designed for masking rectangular and square-shaped components such as bus bar terminals, grounding tabs, and electrical enclosures. Their rectangular shape provides better coverage and fit compared to round caps on square or rectangular features.

What are Eze caps and what makes them

Eze caps (Easy Pull Tab caps) feature an ergonomic finger pull-tab or extended tab design that makes removal quick and effortless. This eliminates the need for tools during removal, reducing the risk of damage to threads or part surfaces while speeding up the masking process.

Why choose caps with pull tabs over standard caps?

Pull-tab caps offer several advantages: faster removal without tools, reduced risk of damaging delicate surfaces or threads, improved efficiency in production environments, and easier handling when wearing gloves. They're particularly valuable in high-volume coating operations.

How do I prevent caps from blowing off during powder coating?

For tube end applications, create a small slit in the top of the cap to allow air pressure to escape, preventing blow-off during the coating process. Ensure proper sizing (cap ID should be 2-5% smaller than the part diameter) for a secure fit.

Can silicone caps be used for shot blasting applications?

Absolutely. Silicone caps are commonly used in shot blasting operations to protect threaded holes, studs, and sensitive surfaces from abrasive media. Their flexibility and durability make them ideal for withstanding the mechanical forces involved in blasting processes.

How do I remove coating build-up from reusable silicone caps?

Simply flex and squeeze the silicone cap after use. The flexibility of the material causes any dried coating to crack and flake off, returning the cap to near-new condition. Avoid using sharp tools or pliers, as silicone has low tear resistance.

What's the difference between ID (inside diameter) and OD (outside diameter) when selecting caps?

Inside Diameter (ID) is the internal measurement of the cap opening - this should be 2-5% smaller than your stud/bolt diameter for proper fit. Outside Diameter (OD) is the external measurement of the cap. When using caps as plugs, the OD should be at least 7% larger than the hole diameter.

How long should my silicone cap be?

Select a cap length that's slightly longer than the area you need to mask. This ensures complete coverage and makes removal easier. If the cap ID is very close to the stud diameter (less than 5% difference), choose a longer cap to provide adequate grip for removal.

How should I store silicone caps for maximum lifespan?

Store silicone caps in a cool, dry place away from direct sunlight and ozone sources. Avoid contact with oils, solvents, or sharp objects. Proper storage helps maintain the material's flexibility and extends service life.

How many times can I reuse silicone caps?

With proper care and within temperature limits, quality silicone caps can be reused dozens of times. The exact number depends on the application severity, temperature exposure, and handling care. Replace caps when they show signs of cracking, hardening, or permanent deformation.

What's the shelf life of silicone caps?

When stored properly, silicone caps have an excellent shelf life of several years. Silicone doesn't degrade significantly over time when stored correctly, making it economical to stock various sizes for different applications.

How fast can I get my order?

Need your parts tomorrow? Our rapid same day dispatch has got you covered! Simply place your order before 4pm Mon-Thurs or 2pm Friday and select our Next Day Delivery service in the shopping cart. We also offer Guaranteed AM delivery when required, in addition to a Saturday delivery option.

If you don't mind waiting, we have a Free delivery method for orders over £30, and an economic £4.85 2nd Class delivery for orders between £20-£30.

Can I get a Free Sample?

Free Samples can be requested through our product pages, displayed in the sizing table beside the product you require. Please note you can always give us a call on 01233 713 581 or contact us on Live Chat to discuss samples.

Do I need to Sign Up for an account?

You do not need to sign up to place an order, but it is recommended if you'd like to gain loyalty points, giving discount off future orders. To learn more about loyalty points, please view our rewards scheme page.

I am not sure what parts I need?

If you're unsure which part you need then please do not hesitate to give one of our friendly Sales Team a call on 01233 713 581 and they can assist you. Alternatively, we're active on Live Chat during office hours. You can open this using the button in the bottom right corner of the website. Alternatively, you can write to us using our contact form.

Do you offer Returns on Products?

We offer a return period on all of our products to give you peace of mind, to view our policies and learn more about this process should it be required, please see our returns policy page.

Can you supply different colours of this product?

In most cases we have the facilities to offer you different colours of a product, specific to your requirements. Minimum order quantities may apply depending on the manufacturing technique in question, but please get in touch with any queries you may have.

Is there a minimum order value?

Please note that there is a minimum order value of £10 through our website (inclusive of VAT).

If you're new to our website you may want to check out our frequently asked questions section for answers to common customer queries.

What do these abbrievations mean?

While browsing the website you may come across abbreviations used for material names that you are unfamiliar with. You can find an explanation for these in our material abbreviations guide.