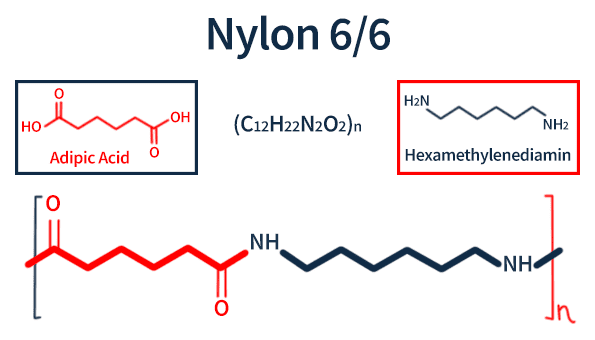

Nylon is a family of polymers. Although the two popular Nylons, which are Nylon 6 and Nylon 66, have some shared characteristics, they also have their differences. This article will ensure you know more about the differences between these two materials. You will also come to know about their chemical structure based on the type and quantity of polymer chains.

Nylon has one monomer, Nylon 66 has two monomers. The one monomer of carbon in Nylon 6 has six carbon atoms, and the two monomers of Nylon 66 have six carbon atoms each. Thus, Nylon 66 has twelve total carbon atoms, which makes it stiffer and typically more durable.

Nylon And UV Rays

Nylon is vulnerable to UV rays unless special additives, like stabilisers, are combined. Nylon 66 is the most sensitive of all the Nylons to UV; however, Nylon 6 is also vulnerable without stabilisers. When Nylon is overexposed to UV light, it is damaged by the breaking down of the molecular bonds in the fibre structure and the UV light interfacing with the chemical structure’s pi electrons.Thus, Polymers that do not have pi electrons are better resistant to UV rays. The good thing is that with stabilisers, Nylon can perform very well outdoors.

Nylon 6 and Nylon 66 for Manufacturing

Both Nylon 6 and Nylon 66 are good choices when it comes to manufacturing. Nylon 6 has a low melting point, while Nylon 66 has a higher melting point, which can make it difficult to process Nylon 66. Nylon 6 has better capability to withstand high impact and stress when compared to Nylon 66. It can be processed at lower temperatures and is less crystalline, resulting in lower mould shrinkage and closer tolerances. It is also available in transparent grades.

When Nylon 66 is put through ambient air temperatures and starts to solidify, it shows greater mould shrinkage, and its shape can alter. Nevertheless, manufacturers can take care of this issue by increasing the dimensions of extrusion dies and injection moulds. As the mould shrinkage is low, it processes much easier, and manufacturers get more dependable final part dimensions.Although Nylon 6 has a higher water absorption rate when compared to Nylon 66, it too will have to be dried before being moulded as Nylon 6 is known to absorb moisture from the air. If Nylon 6 is not dried, it will result in slants and marks on its surfaces. If manufacturers skip the drying process, the oxidation will result in material degradation, which in turn will result in weakened mechanical properties.

Glass-Filled Nylon

Glass-filled Nylon is created by adding powdered glass to Nylon resins, which increases its tensile strength, compression strength, and stiffness. As Nylon absorbs moisture, it results in the expansion of the material. Adding glass to the Nylon solves this problem because it improves stability when the Nylon is put through temperature changes. For enhancing the strength of Nylon, manufacturers often use Glass-filled Nylon because the process can toughen Nylon by over 70%.

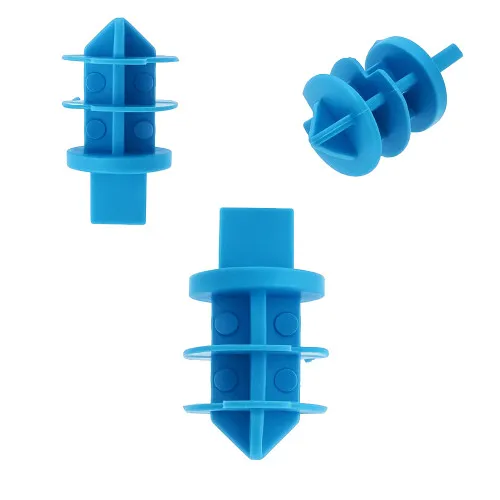

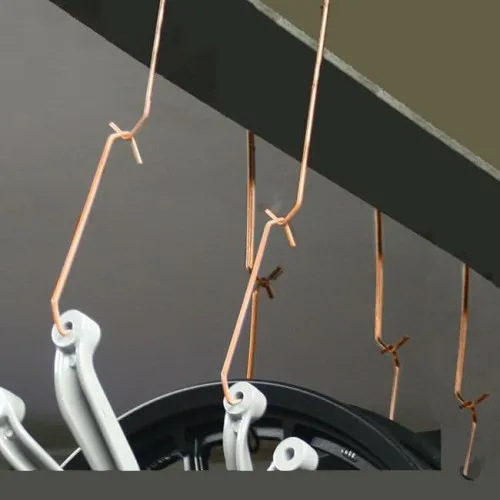

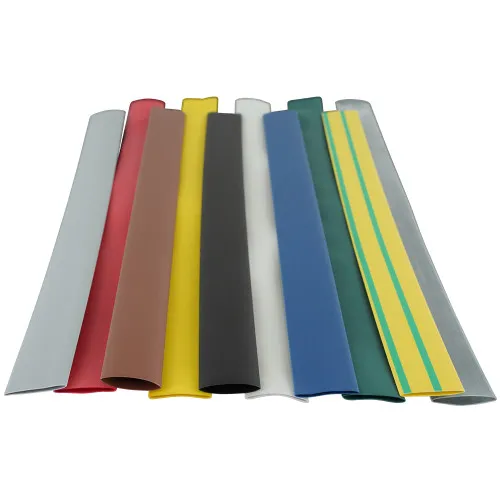

Nylon Cable Ties

One of the many products that is manufactured from Nylon 66, and which we sell here at Vital Parts, is our Nylon Cable Ties. We supply a range of Cable Ties manufactured from a high quality Nylon 66 in a huge range of sizes and colour options. Being UL94V-2 rated, these can be used within new-build and construction related projects where a level of flammability resistance is required for health and safety purposes, to reduce the risk of exposure to open flames.

Other than black and clear, we also offer Coloured Cable Ties, as well as Cable Tie Kits. Our Cable Tie Mounts, as well as their Adhesive Versions, are also manufactured from a sturdy Nylon.

Nylon And Other Plastics

Even with the many advantages of both Nylon 6 and Nylon 66, the material cannot be used for every application. Any project that uses plastics must use the ideal material, and other plastics may well be better for certain projects. Our expert team can help in any case of plastic uses for projects, as well as custom products and components, where needed. Call us on 01233 713581, or visit our Contact Us page Here to get in touch!