Categories

-

Plugs & Stoppers

-

Tapered Rubber Plugs

Tapered Rubber Plugs -

Blanking Plugs

Blanking Plugs -

Ventilation Plugs

Ventilation Plugs -

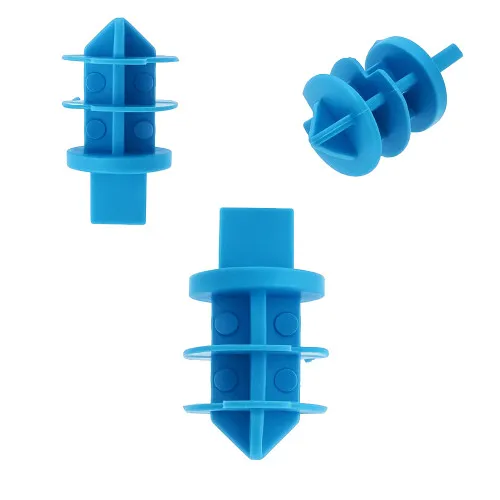

Fir Tree Plugs

Fir Tree Plugs -

Snap Fit Bushes

Snap Fit Bushes -

Liquid Tight Plugs

Liquid Tight Plugs -

Threaded Plugs

Threaded Plugs -

Threaded Sealing Plugs

Threaded Sealing Plugs -

Reversible Tapered Plugs

Reversible Tapered Plugs -

Washer Masking Plugs

Washer Masking Plugs -

Silicone Tapered Plugs

Silicone Tapered Plugs -

Silicone Ribbed Plugs

Silicone Ribbed Plugs -

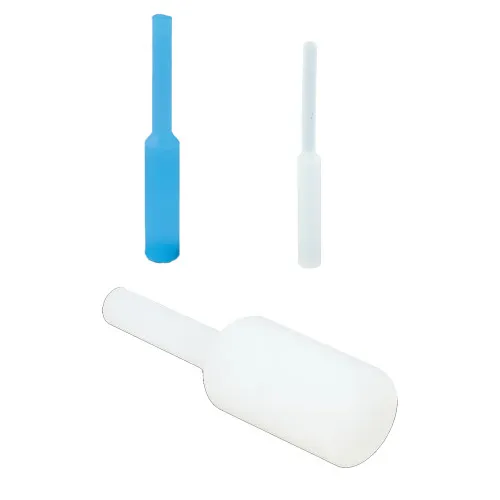

Silicone Plugs With Handle

Silicone Plugs With Handle -

Silicone Step Plugs

Silicone Step Plugs -

Silicone Pull Plugs

Silicone Pull Plugs -

Silicone Thread Masking Plugs

Silicone Thread Masking Plugs -

Barrel Plugs

Barrel Plugs -

Cylindrical Pull Tab Plugs

Cylindrical Pull Tab Plugs -

Finned Pull Tab Plugs

Finned Pull Tab Plugs -

Round Tube Plugs

Round Tube Plugs -

Snap Fit Hole Plugs

Snap Fit Hole Plugs -

Ribbed Pipe End Plugs

Ribbed Pipe End Plugs -

Door Stoppers

Door Stoppers -

Finned Hole Plugs

Finned Hole Plugs -

Silicone Double Flange Plugs

Silicone Double Flange Plugs -

Silicone Flange Plugs

Silicone Flange Plugs -

Silicone Washer Plugs

Silicone Washer Plugs -

Plastic End Plugs

Plastic End Plugs -

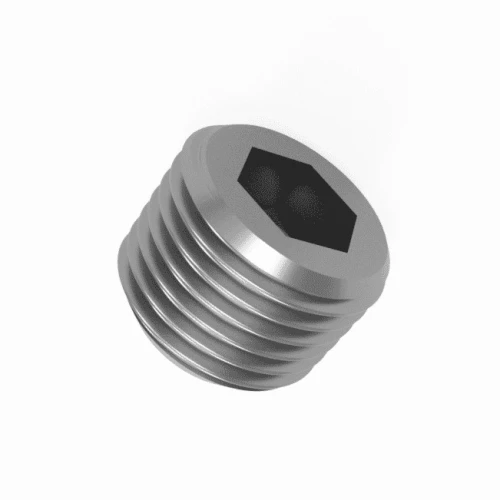

Stainless Steel Socket Pipe Plugs DIN 906

Stainless Steel Socket Pipe Plugs DIN 906

-

-

Furniture & Chair Feet

-

Adjustable Feet

-

Slotted Head Adjustable Feet

Slotted Head Adjustable Feet -

Rubber Adjustable Feet

Rubber Adjustable Feet -

Stainless Steel Adjustable Feet

Stainless Steel Adjustable Feet -

Ready To Install Sets

Ready To Install Sets -

One Piece Adjustable Feet

One Piece Adjustable Feet -

General Adjustable Feet

General Adjustable Feet -

Low Profile Adjustable Feet

Low Profile Adjustable Feet -

Machinery Mounting Feet

Machinery Mounting Feet -

Weight Rated Articulated Feet

Weight Rated Articulated Feet -

Heavy Duty Tilting Feet

Heavy Duty Tilting Feet -

Tilting Adjustable Feet

Tilting Adjustable Feet -

Metal Adjustable Feet

Metal Adjustable Feet -

Economic Adjustable Feet

Economic Adjustable Feet -

Allen Key Adjustable Feet

Allen Key Adjustable Feet -

Anti-Vibration Levelling Feet

Anti-Vibration Levelling Feet -

Balance Feet

Balance Feet -

Polyamide Adjustable Feet

Polyamide Adjustable Feet -

Pozi Base Adjustable Feet

Pozi Base Adjustable Feet -

Hexagon Base Feet

Hexagon Base Feet -

Threaded Fittings & Fixings

Threaded Fittings & Fixings

-

-

Cable Management

-

Cable Glands

Cable Glands -

Strain Relief

Strain Relief -

Rubber Grommets

Rubber Grommets -

Cable Ties

Cable Ties -

Blanking Plugs

Blanking Plugs -

Cable Clips

Cable Clips -

Cable Tie Mounts

Cable Tie Mounts -

Velcro Cable Management

Velcro Cable Management -

Aluminium Cable Clips

Aluminium Cable Clips -

Braided Cable Sleeving

Braided Cable Sleeving -

Multi Cable Clips

Multi Cable Clips -

PVC Cable Sleeving

PVC Cable Sleeving -

Spiral Cable Wrap

Spiral Cable Wrap -

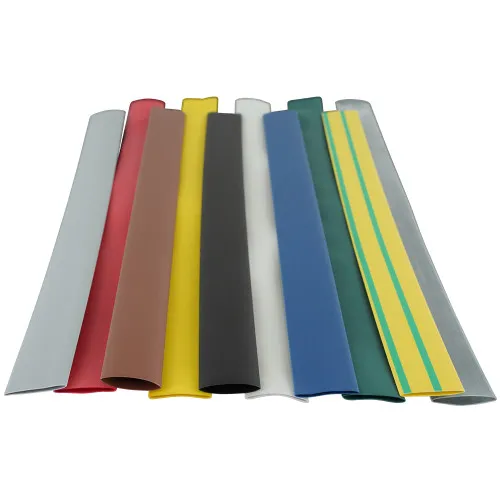

Heat Shrink Sleeves

Heat Shrink Sleeves -

Plastic Grommet Strips

Plastic Grommet Strips -

Adhesive Lined Heatshrink

Adhesive Lined Heatshrink -

Heat Shrink Caps

Heat Shrink Caps -

Nylon P Clips

Nylon P Clips -

Nylon P Clamps

Nylon P Clamps -

Rubber Grommet Strips

Rubber Grommet Strips -

Desk Cable Tidies

Desk Cable Tidies

-

-

Bolts and Screws

-

Hex Head Screws and Bolts

Hex Head Screws and Bolts -

Cap Screws

Cap Screws -

Countersunk Screws

Countersunk Screws -

Button Screws

Button Screws -

Pan Head Machine Screws

Pan Head Machine Screws -

Cheese Head Slotted Screws

Cheese Head Slotted Screws -

Security Fasteners

Security Fasteners -

Self Tapping Screws

Self Tapping Screws -

Wood Screws

Wood Screws -

Screws for Plastic

Screws for Plastic -

Knurled Fasteners

Knurled Fasteners -

Shoulder Bolts

Shoulder Bolts -

Grub Screws

Grub Screws -

Threaded Rod (All Thread)

Threaded Rod (All Thread) -

Weld Studs

Weld Studs -

Number Plate Screws

Number Plate Screws -

Nylon Screws & Bolts

Nylon Screws & Bolts -

Stainless Steel Bolts By Metric Thread Size

Stainless Steel Bolts By Metric Thread Size -

Small Bolts

Small Bolts -

Large Bolts

Large Bolts -

Industrial Hardware

Industrial Hardware

-

-

Washers

-

Stainless Steel Flat Washers

Stainless Steel Flat Washers -

Stainless Steel Spring Washers

Stainless Steel Spring Washers -

Stainless Steel Curved Washers

Stainless Steel Curved Washers -

Stainless Steel Serrated Washers

Stainless Steel Serrated Washers -

Stainless Steel Tab Washers

Stainless Steel Tab Washers -

Stainless Steel Finishing Washers

Stainless Steel Finishing Washers -

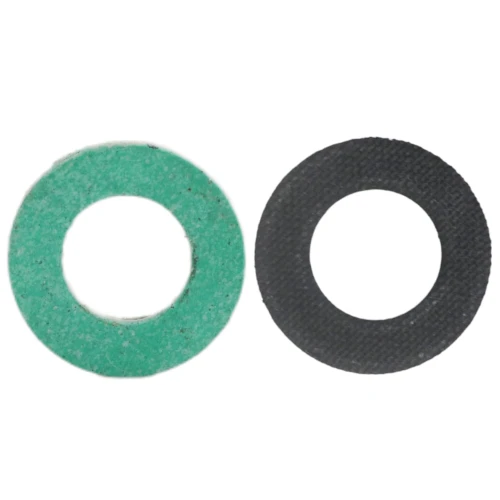

Bonded Sealing Washers

Bonded Sealing Washers -

Standard Nylon Washers

Standard Nylon Washers -

Rubber Washers

Rubber Washers -

Red Fibre Washers

Red Fibre Washers -

Peek Washers

Peek Washers -

Silicone Washers

Silicone Washers -

PTFE Washers

PTFE Washers -

EPDM WRAS Washers

EPDM WRAS Washers -

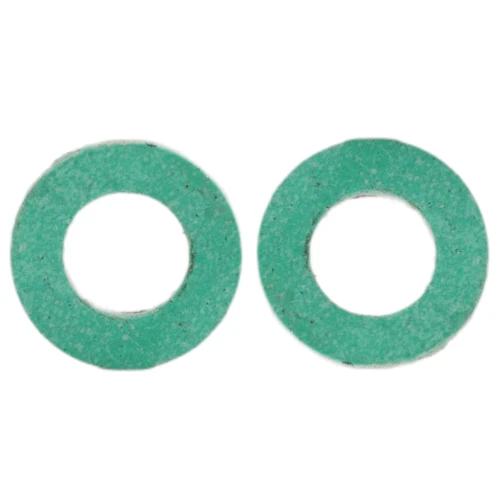

Fibre WRAS Washers

Fibre WRAS Washers -

FKM Washers

FKM Washers -

WRAS Washers

WRAS Washers -

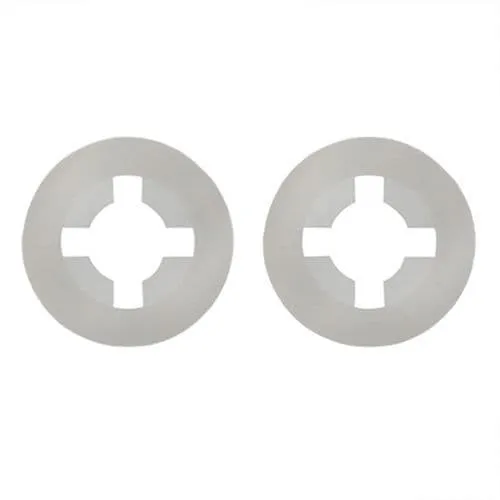

Anti-Loss Washers

Anti-Loss Washers -

Finishing Washers

Finishing Washers -

Headboard Washers

Headboard Washers -

Saddle Washers

Saddle Washers

-

-

Industrial Hardware

-

Hinges

Hinges -

Camlocks

Camlocks -

Latches

Latches -

Detent Pins

Detent Pins -

Index Plungers

Index Plungers -

Clamping Handles

Clamping Handles -

Bridge Handles

Bridge Handles -

Pull Handles

Pull Handles -

Threaded Handwheels

Threaded Handwheels -

Wing Screws & Knobs

Wing Screws & Knobs -

Knurled Thumbscrews

Knurled Thumbscrews -

Ball Knobs

Ball Knobs -

Control Handwheels

Control Handwheels -

Door Bolts

Door Bolts -

Adjustable Feet

Adjustable Feet -

Furniture Fixings

Furniture Fixings -

Plastic & Rubber Grips

Plastic & Rubber Grips -

Roof Support Systems

Roof Support Systems -

Push Fit Knobs

Push Fit Knobs -

Edging Strips

Edging Strips

-

-

Adhesive Tapes

-

PTFE Tape

PTFE Tape -

Packing Tape

Packing Tape -

Fragile Tape

Fragile Tape -

Cloth Tape

Cloth Tape -

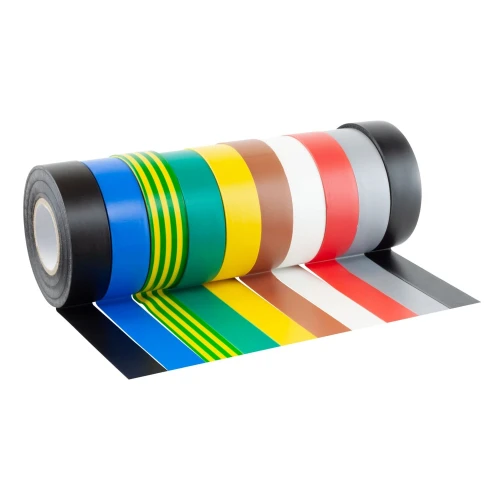

PVC Electrical Insulation Tape

PVC Electrical Insulation Tape -

Floor Marking Tape

Floor Marking Tape -

Safety Hazard Warning Tape

Safety Hazard Warning Tape -

Underground Cable Warning Tape

Underground Cable Warning Tape -

Non Slip Tape

Non Slip Tape -

Non-Adhesive Barrier Tape

Non-Adhesive Barrier Tape -

Double Sided Foam Tape

Double Sided Foam Tape -

UV Resistant Blue Masking Tape

UV Resistant Blue Masking Tape -

High Temp Crepe Tape

High Temp Crepe Tape -

Low Tack Paper Masking Tape

Low Tack Paper Masking Tape -

Aluminium Foil Tape

Aluminium Foil Tape -

Self Amalgamating PVC Tape

Self Amalgamating PVC Tape -

Self Amalgamating Silicone Tape

Self Amalgamating Silicone Tape -

Self Amalgamating EPR Tape

Self Amalgamating EPR Tape -

Fleece Tape

Fleece Tape -

Matte Cloth Tape

Matte Cloth Tape -

Glass Cloth Tape

Glass Cloth Tape -

Red Polyester Tape

Red Polyester Tape -

Anti Static Polyimide Tape

Anti Static Polyimide Tape -

Amber Polyimide Tape

Amber Polyimide Tape -

Green Polyester Tape

Green Polyester Tape -

Blue Polyester Tape

Blue Polyester Tape

-

-

Panel Fasteners

-

School & Office Products

-

Rubber Seals

-

Business Services

- Business Account

- Knowledge Hub

- Custom Moulding Services

| Quantity |

Unit Price

(ex. VAT)

|

Unit Price

(inc. VAT)

|

|---|---|---|

| 2 - 99 | £0.32 | £0.38 |

| 100 - 499 | £0.27 | £0.32 |

| 500 - 999 | £0.21 | £0.25 |

| 1000 + | £0.17 | £0.21 |

Product Stock

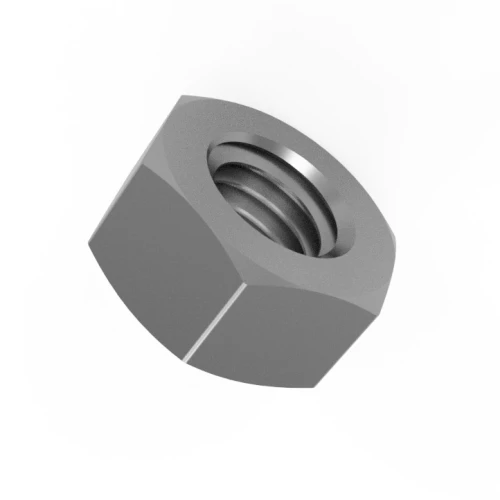

| Product Specifications | W6319C-M6-A4 |

|---|---|

| Size | M6 |

| Internal Diameter | 6.4mm |

| Outside Diameter | 12mm |

| Height | 2.3mm |

| Step Height | 0.7mm |

| Standard | DIN 6319C |

| Material | A4 Stainless Steel |

Same Day Dispatch Available

Order by 4pm (UK) for same day dispatch (Monday – Thursday, 2pm Friday). Next Day or Standard Delivery available via DHL or Royal Mail.

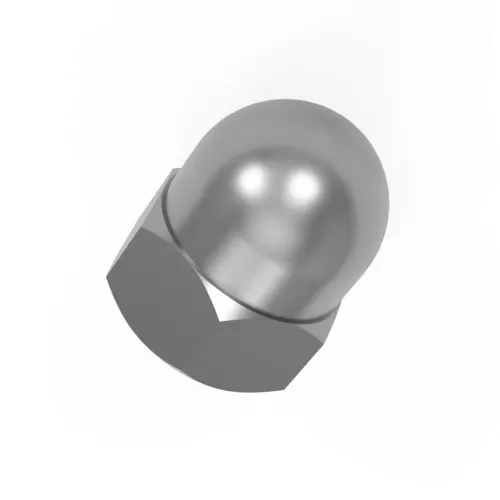

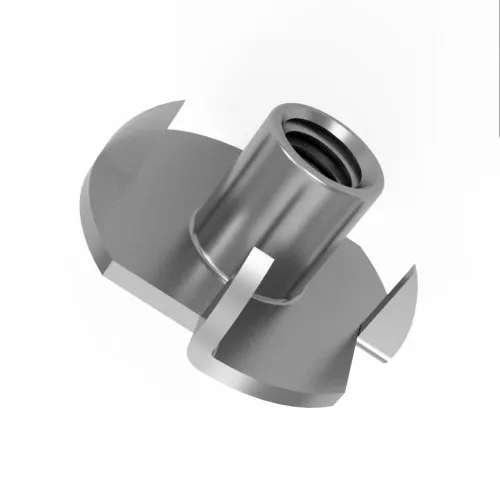

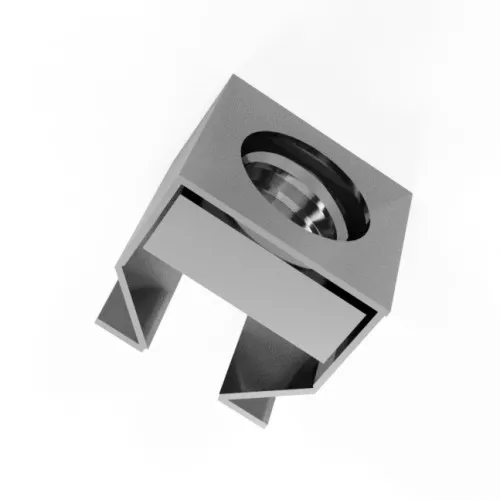

Frequently Bought Together

- Material A4 Stainless Steel

- Height 2.8mm

- Internal Diameter 7.1mm

- Outside Diameter 12mm

- Standard DIN 6319D

- Size M6

- Material A4 Stainless Steel

- Thickness 1.6mm

- Internal Diameter 6.4mm

- Outside Diameter 12.0mm

- Standard DIN 125A

- Size M6

Total Price: £0.00

Product Description

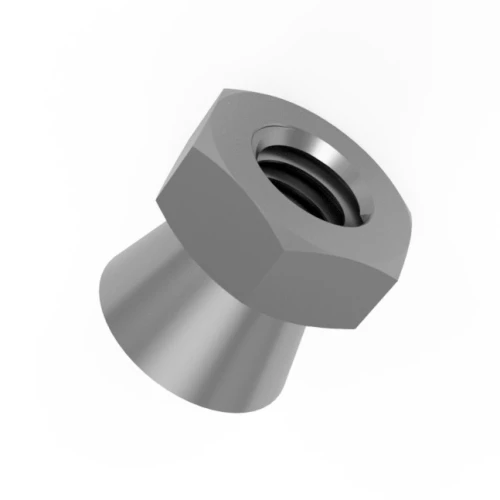

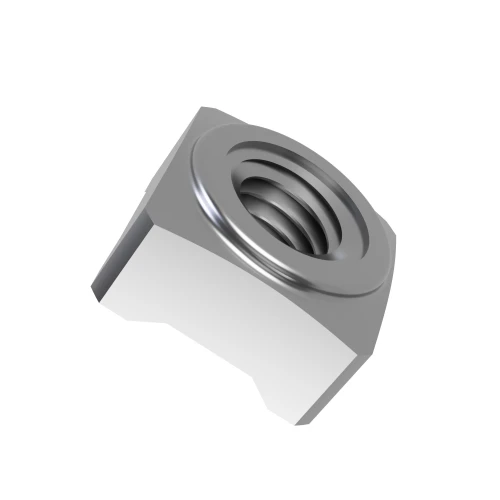

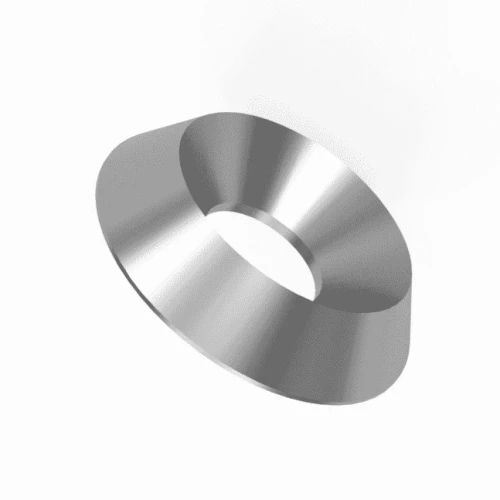

DIN 6319C Spherical Washers

Precision Alignment for Secure Fastening

Achieve optimal clamping and secure fastening even on non-parallel or uneven surfaces with our high-quality DIN 6319C Spherical Washers. These precision-engineered components are designed to compensate for angular misalignment, ensuring that clamping forces are evenly distributed and that bolts or studs remain perpendicular to the load. This critical function prevents concentrated stress points, reduces the risk of fastener fatigue, and significantly enhances the reliability and longevity of your assembled components.

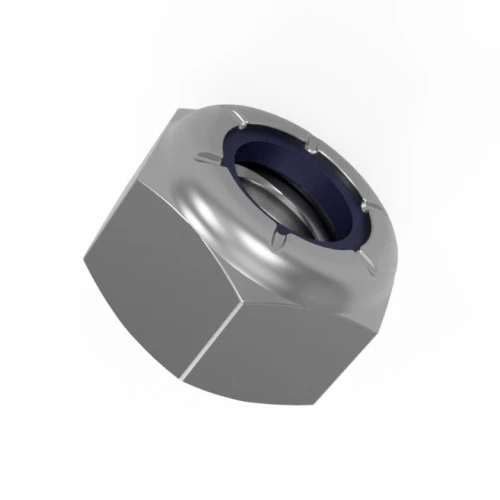

How to Use & Pair with DIN 6319D Conical Seating Washers

The DIN 6319C Spherical Washer features a convex bottom surface. It is designed to be used in conjunction with its complementary DIN 6319D Conical Seating Washer, which features a concave top surface.

- Assembly: Place the DIN 6319D Conical Seating Washer (the one with the "cup" shape) against the irregular or angled surface.

- Placement: Then, place the DIN 6319C Spherical Washer (the one with the "ball" shape) on top of the DIN 6319D, ensuring their mating surfaces nest perfectly.

- Fastening: Insert your bolt or stud through both washers. As you tighten the nut, the spherical washer will pivot within the conical seating washer, creating a self-aligning system. This ensures the clamping force is applied axially and uniformly, accommodating angular variations up to 3 degrees.

This robust pairing is essential for creating a stable and stress-free connection on non-parallel surfaces.

Key Features & Specifications:

- Standard: Manufactured to DIN 6319C for reliable dimensions and performance.

- Size: Available in various sizes from M6 to M30

- Material: Crafted from high-grade A2 or A4 stainless steel offering exceptional durability and corrosion resistance.

- Function: Compensates for angular misalignment up to 3 degrees.

- Compatibility: Designed for optimal performance when paired with DIN 6319D Conical Seating Washers.

When and Where to Use DIN 6319C Spherical Washers:

These washers are vital wherever precision alignment and even clamping are critical, especially in environments with inherent surface irregularities or demanding loads:

- Fixture and Tooling Construction: Essential in jigs and fixtures where workpieces may have slight irregularities or where clamping elements need to apply force precisely at an angle.

Example: Securing a component to a machining bed where the surface isn't perfectly flat, ensuring the clamp holds true without bending the bolt.

- Machine Building: Used in various machinery assemblies to compensate for manufacturing tolerances or deflection, ensuring smooth operation and preventing premature wear.

Example: Mounting motors, pumps, or other critical components to a base plate that may have minor surface imperfections or settling over time.

- Heavy-Duty Clamping Applications: In situations where a bolt is used to clamp two parts together, and one or both surfaces are not perfectly perpendicular to the bolt's axis.

Example: Fastening structural elements in heavy machinery or presses where high, consistent clamping force is required across slightly angled surfaces.

- Die and Mould Construction: Critical for the precise alignment and secure fastening of components within dies and moulds, where even the slightest misalignment can impact product quality and tool life.

Example: Ensuring the precise closure of mould halves or the secure mounting of interchangeable die components.

By integrating our DIN 6319C Spherical Washers, you ensure a stronger, more reliable, and longer-lasting assembly, even in the most challenging conditions.

Related Products

| Code | Material | Height | Internal Diameter | Outside Diameter | Standard | Size | Step Height | Stock | |

|---|---|---|---|---|---|---|---|---|---|

| W6319C-M10-A4 | A4 Stainless Steel | 4.0mm | 10.5mm | 21mm | DIN 6319C | M10 | 0.8mm |

Checking...

|

|

| W6319C-M14-A4 | A4 Stainless Steel | 5.0mm | 15mm | 28mm | DIN 6319C | M14 | 1.2mm |

Checking...

|

|

| W6319C-M16-A4 | A4 Stainless Steel | 5.3mm | 17mm | 30mm | DIN 6319C | M16 | 1.3mm |

Checking...

|

|

| W6319C-M20-A4 | A4 Stainless Steel | 6.3mm | 21mm | 36mm | DIN 6319C | M20 | 2.0mm |

Checking...

|

|

| W6319C-M24-A4 | A4 Stainless Steel | 8.2mm | 25mm | 44mm | DIN 6319C | M24 | 2.4mm |

Checking...

|

|

| W6319C-M30-A4 | A4 Stainless Steel | 11.2mm | 31mm | 56mm | DIN 6319C | M30 | 3.6mm |

Checking...

|

|

| W6319C-M6-A4 | A4 Stainless Steel | 2.3mm | 6.4mm | 12mm | DIN 6319C | M6 | 0.7mm |

Checking...

|

|

| W6319C-M8-A4 | A4 Stainless Steel | 3.2mm | 8.4mm | 17mm | DIN 6319C | M8 | 0.6mm |

Checking...

|

|

Fri 8.30 am - 3.30 pm

Recently Viewed