Welcome to the Vital Parts Guide to Installing Tube Inserts

WHEN TO USE TUBE INSERTS:

01

TO FINISH OFF A TUBE OR PIPE:

02

FOR USE AS FEET WITH TUBULAR CHAIR OR FURNITURE LEGS:

03

TO PROTECT THE INTERNAL SECTION FROM INGRESS:

04

TO ADD A FUNCTION OR THREAD WHEN FLOW DRILLING:

WHY USE TUBE INSERTS:

There are many different reasons as to why you may choose to use Tube Inserts over other solutions available, from ease of use to the quality of finish they provide. Below, we have listed some of the main reasons to use them.

EASY TO FIT:

COST EFFECTIVE:

HUGE RANGE OF SIZES AND STYLES:

HOW TO MEASURE TUBE INSERTS:

When looking to measure Tube Inserts, it is essential to have a good idea of the exact measurements that are required for a secure fit and a reliable finish and function. Below, we have split up some of the key measurements that need to be taken to ensure the best fit, first time.

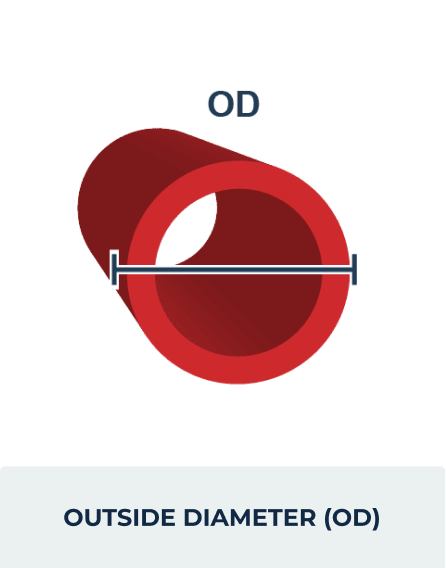

Outside Diameter (OD)

Outside Diameter (OD)

Finding the Outside Diameter of a tube is done by measuring the distance between the two outer lips of your application. The distance between the two lips will be your measurement for the Outside Diameter.

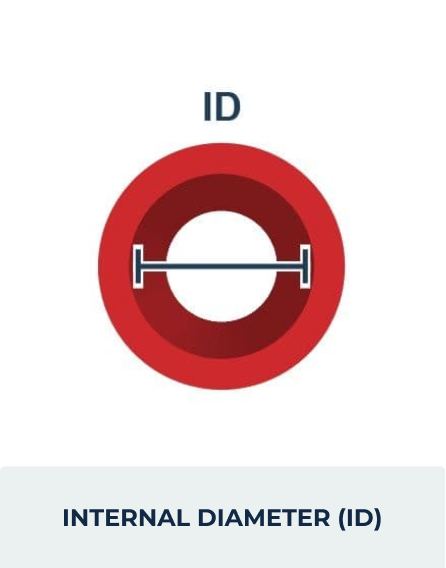

Internal Diameter (ID)

Internal Diameter (ID)

The next step to finding your measurement is to find the Internal Diameter of your tube. This is done in a similar way to the Outside Diameter, however the measurement is taken from the distance between the two inner lips rather than the outer.

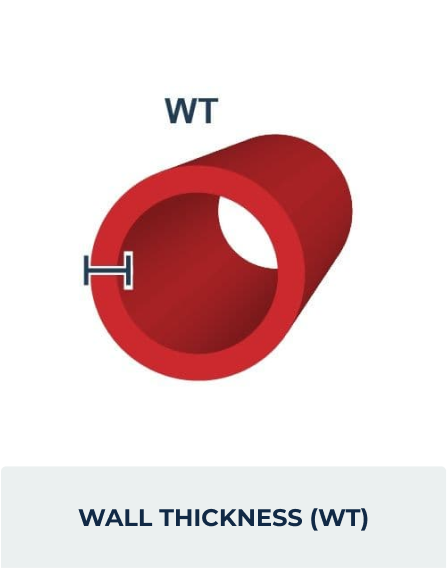

Wall Thickness (WT)

Wall Thickness (WT)

Once have the two main measurements of your tube (ID & OD) you can start to work out the Wall Thickness range that you will require for a secure fitting. This measurement is found by using the following measurement: (OD - ID ÷ 2 = Wall Thickness)

Once you have all three of the required measurements, you can start to look for your required sizing. To do this you want to match up your tubes OD with the inserts OD listed on our product page, as this will help you to identify the best fit.

It is important to make sure that the measurement that you came up with for the Wall Thickness fits inside the range disclosed on the relevant product page. For example, if you have an insert with an OD of 30mm and a wall thickness of 1-3mm, then this will fit a tube that has an OD of 30mm and a wall thickness between 1-3mm.

Please note that in some cases, Tube Inserts are able to fit across a range of tube diameters thanks to their flexible ribs, which can flex when pushed inside.

*To Fit Tube Size is available on the majority of our standard Tube Inserts range, which means the above wall thickness calculation has been done for you. Simply match up your size to the given to fit tube sizing range where given within the product measurements.

HOW TO INSTALL TUBE INSERTS:

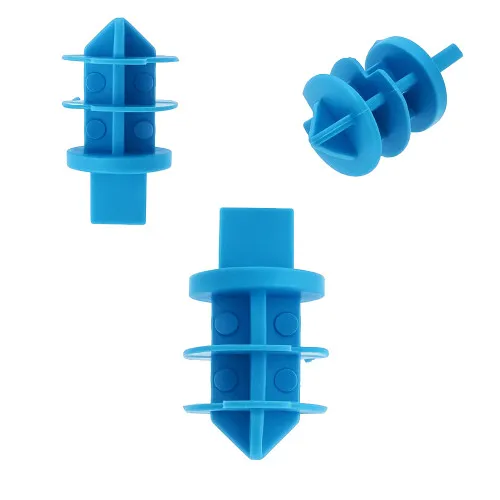

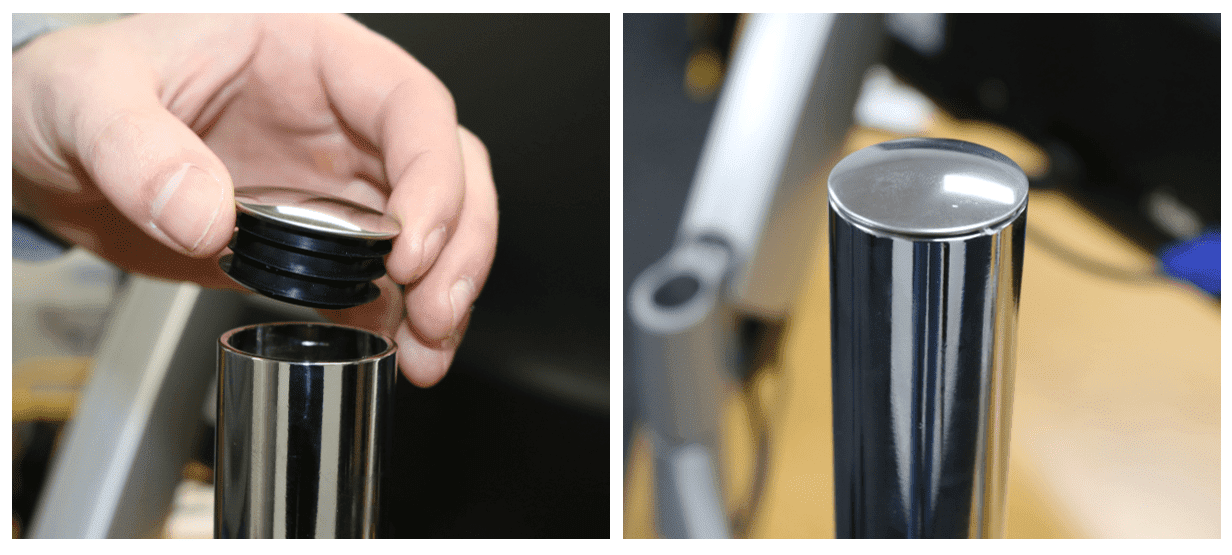

Installation as displayed in the image below, is a quick and simple process. Our inserts require just a tap by hand or hammer to provide a tight and secure fitting. Due to the ribbed nature of this product, these hold inside the tube without the need for fixings, fasteners or adhesives.

WHAT'S AVAILABLE IN OUR TUBE INSERTS RANGE?

Our range of Tube Inserts feature both standard and bespoke products for a number of uses. These vary from finishing off a tube to connecting two tubes together. To get a better understanding and to give an overview of what we have on offer, please see the different types summarised below.

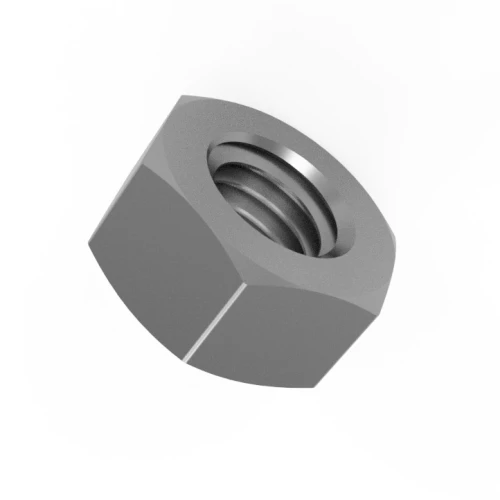

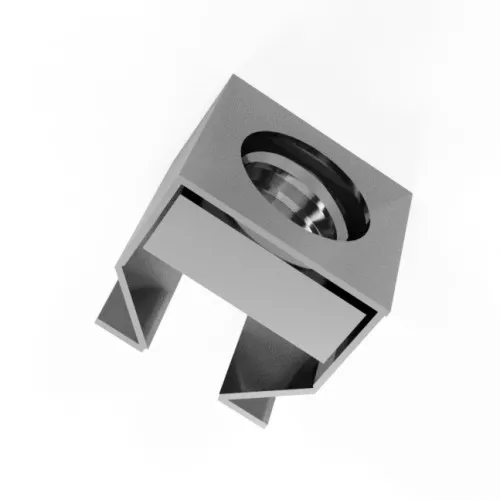

Standard Tube Inserts

Standard Tube Inserts are one of the most cost effective fitting options that we provide. They come in all common shapes and sizes (such as Round, Square, Oval and Rectangular). Manufactured from durable materials such as LDPE Plastic and Nylon, these are to go-to product range for most generic uses.

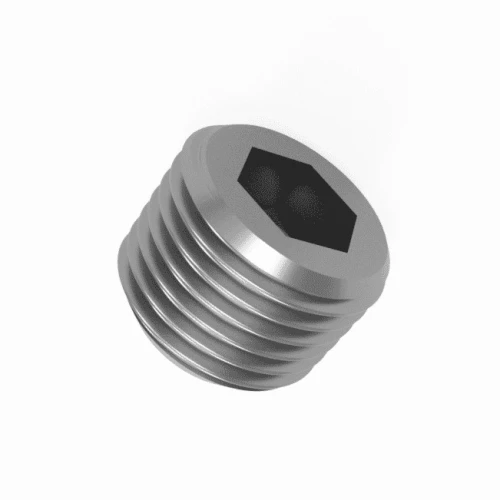

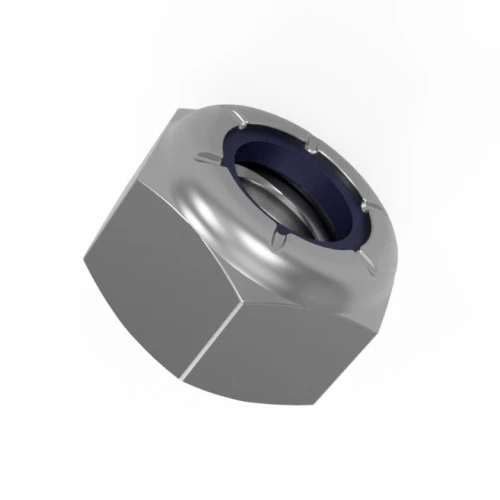

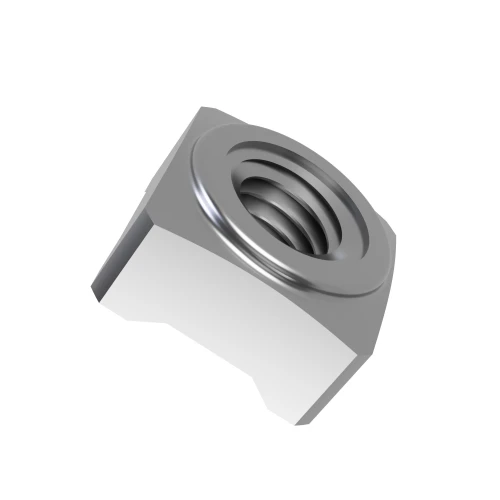

Threaded Tube Inserts

Threaded Tube Inserts are unique in the sense that they allow for the attachment of male threaded components to a tube (popular during flowdrilling or metal fabrication). They are available in a range of female metric thread sizes between M6 to M20 and a selection of shapes to suit differing tube styles.

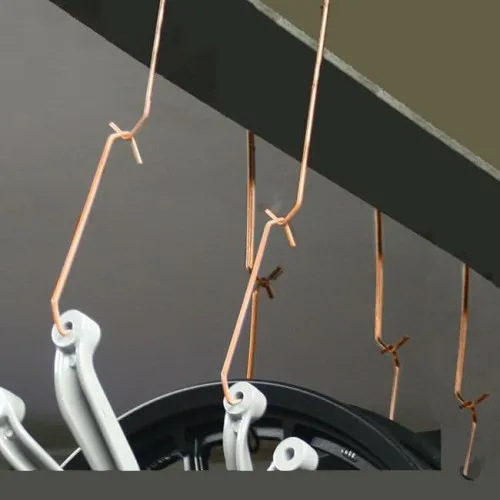

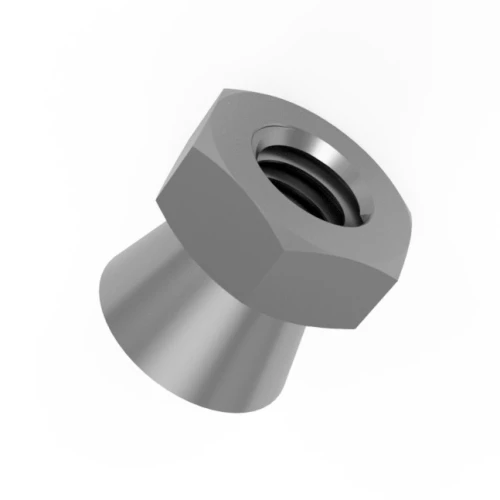

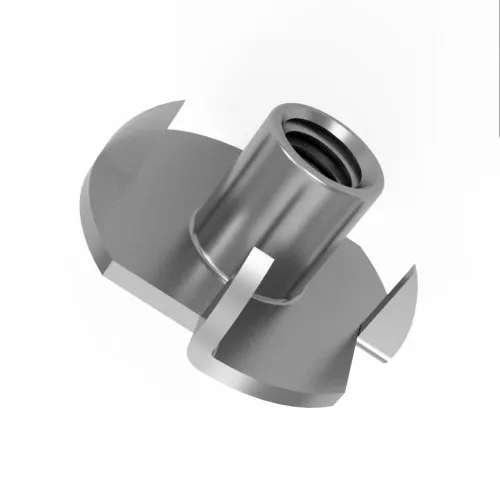

Tube Connectors

Tube Connectors are a bespoke style of insert. They are manufactured specifically for the connection of tubular frames. Popular for use inside industries that deal with temporary stands and attractions, these offer the ability to connect a full metal frame.

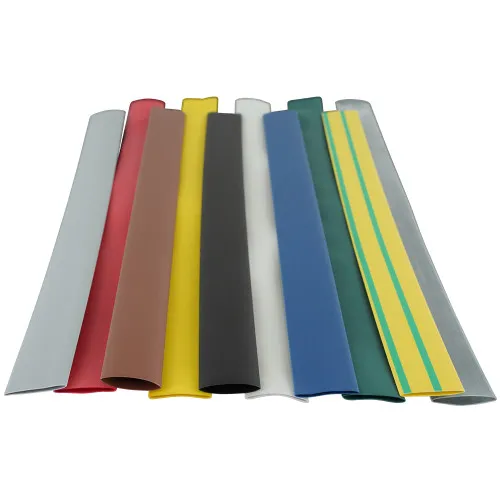

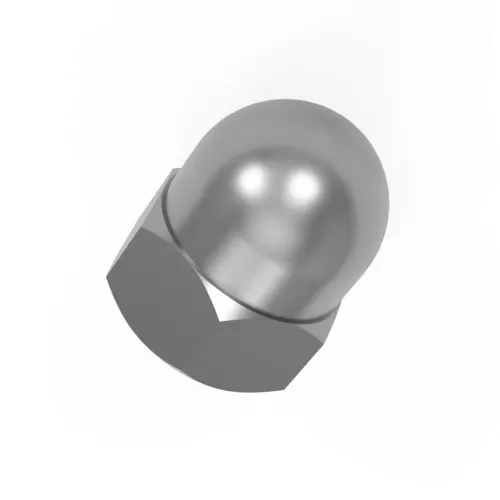

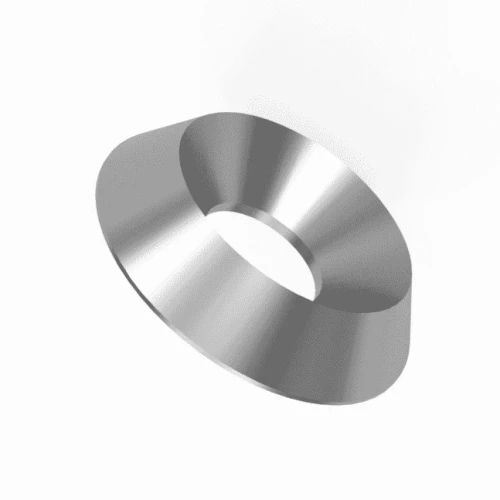

Glides

Glides are essentially feet made to promote loss of grip, enabling quick and easy movement across hard and soft surfaces. They are often used inside consumer industries to increase comfort and reduce noise. Glides are an extremely popular choice.

- Nail On: PTFE/Felt/Metal/Plastic

- Screw On: PTFE/Teflon/Felt

- Push In: Felt / PTFE

- Threaded: Nylon / PE