WHEN TO USE END CAPS:

01

TO COVER OR PROTECT AN APPLICATION:

02

TO FINISH OFF AN OBJECT:

03

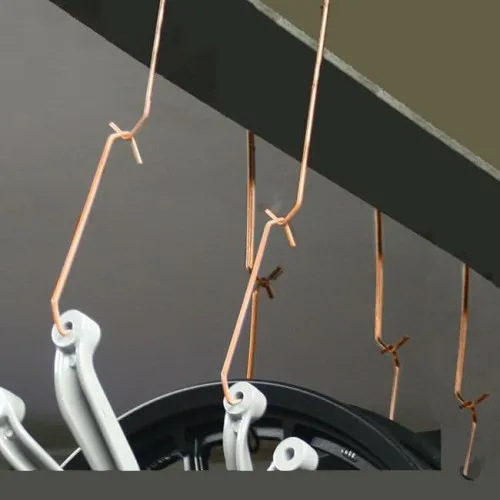

TO MASK OFF AN APPLICATION:

COST EFFICIENCY:

EASE OF USE:

VARIETY OF SIZES:

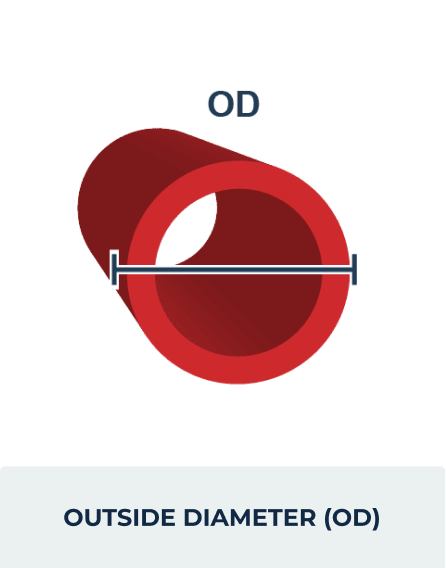

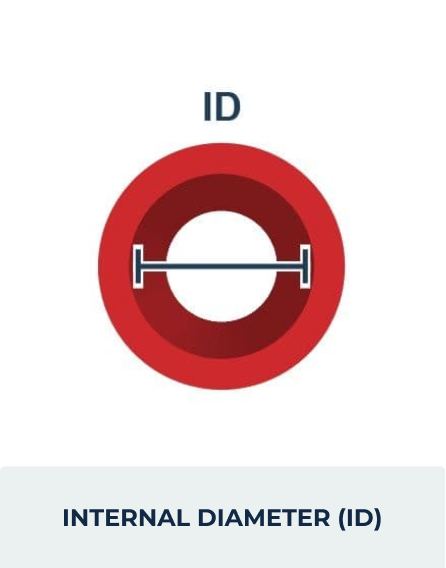

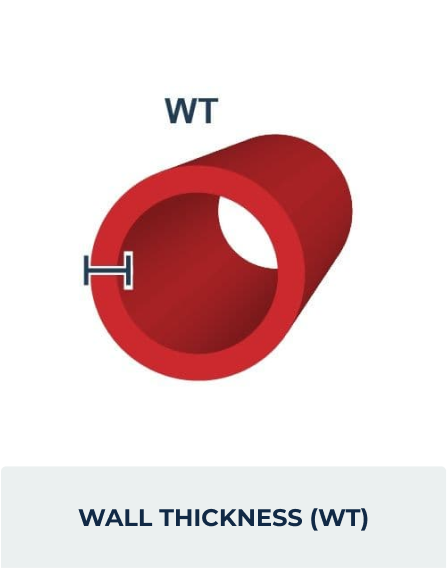

HOW TO MEASURE END CAPS:

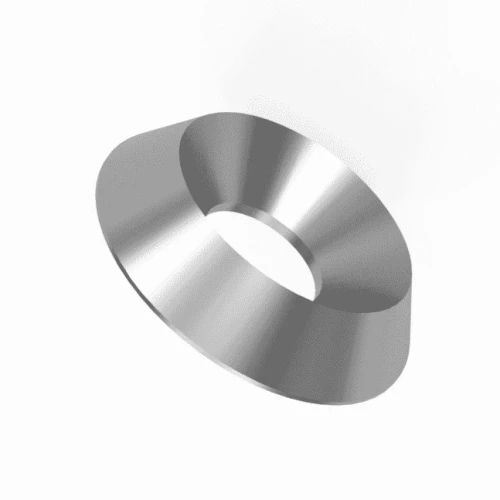

Caps are a relatively simple product to measure. They share many similarities with Tube Inserts. The most important measurements to consider are the Outside Diameter and Internal Diameter. Here's a quick run-down of how you can get those measurements, for matching up on our site.

Firstly, you want to find the Outer Diameter of your application. This is done by working out the distance between both of the outer edges of your object.

Secondly, once you have the Outer Diameter correct, you want to match this up with the Internal Diameter (which is often the measurement used on our cap products). Matching up your Outside with the Internal measurement will provide a tight and secure fitting

Due to the materials used, you may find that certain products have the ability to stretch across a range of diameters, preventing the need for an exact measurement.

WHAT'S AVAILABLE IN OUR END CAPS RANGE?

Our selection covers a huge number of uses, from specialist to basic and every day. These products come mainly in either Rubber or Plastic designs. There are many different properties available depending on your use, which can be easily matched up to requirements. Below, we have split each product range into two different categories. This should help to outline our selection and ease navigation.

Plastic

End Caps manufactured from Plastic derivatives are most commonly used for finishing, protecting, and covering uses. They are available in a number of bespoke and general styles to suit your application. .

- Tube End Caps

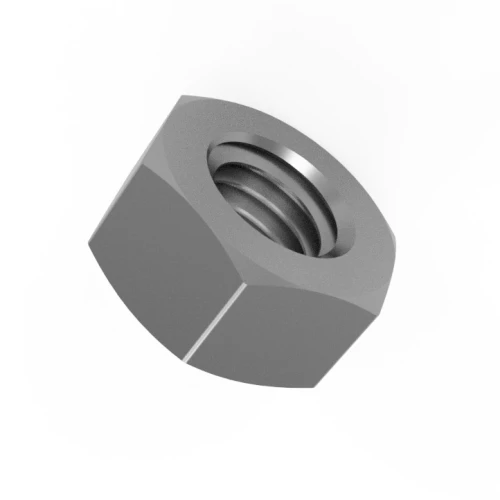

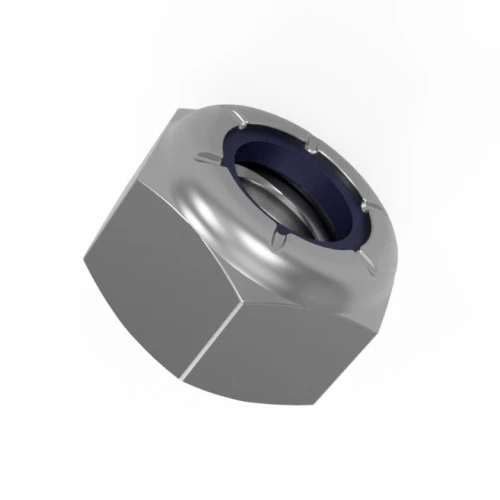

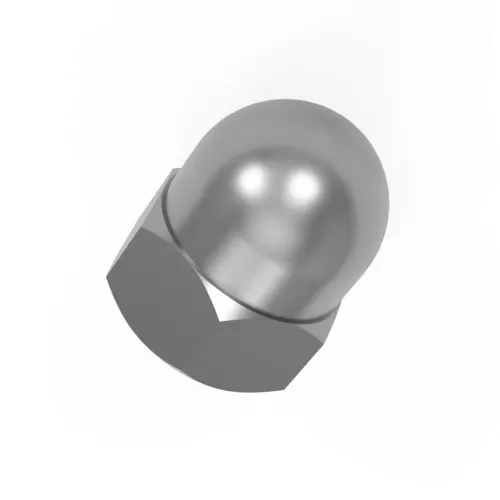

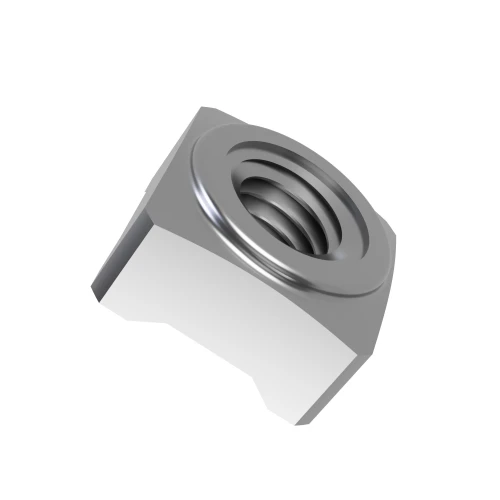

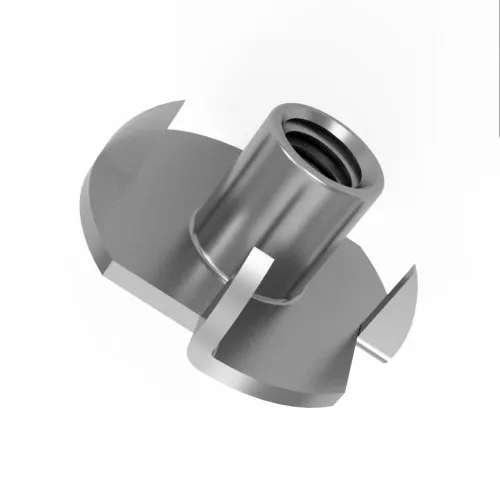

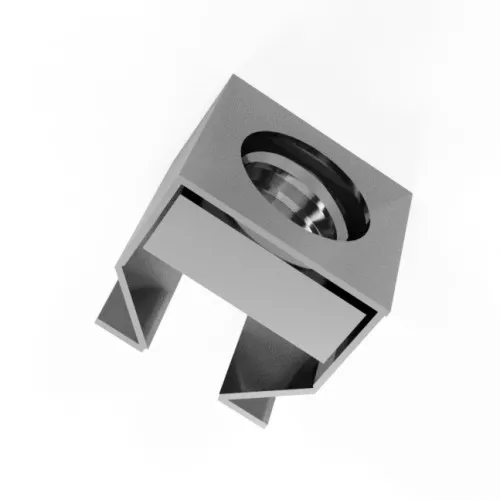

- Nut Caps/Secure Nut Caps

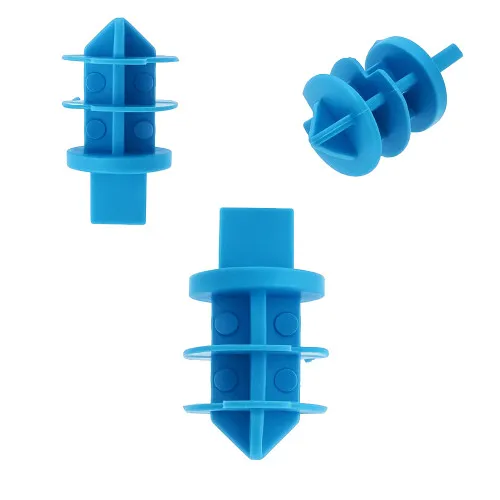

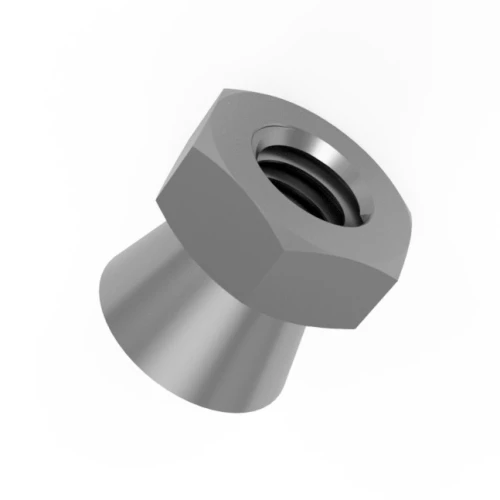

- Tapered Caps

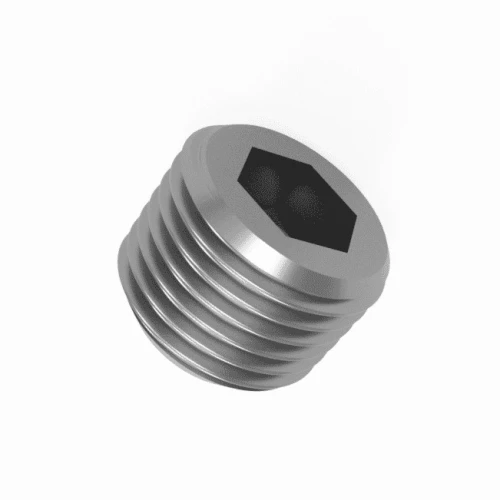

- Threaded Caps

- Sealing Caps

- Rebard Caps

- Grease Caps

- Post Caps

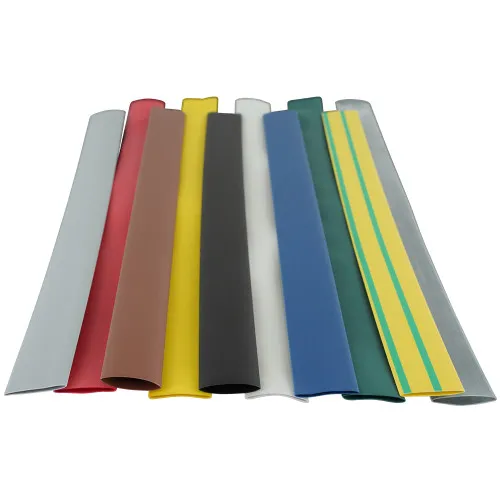

- Heatshrink Caps