No Products Found

Return Home

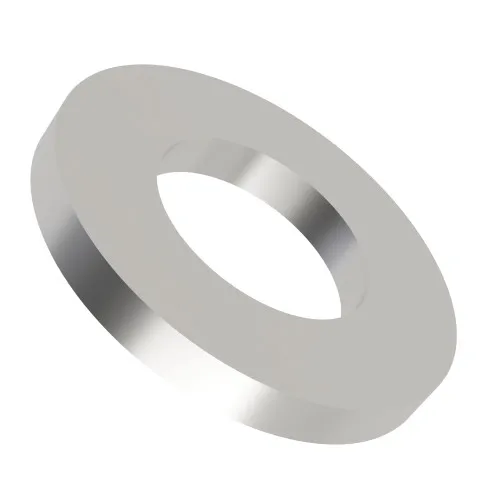

Titanium washers are precision-engineered components made from Titanium alloys, prized for their exceptional strength-to-weight ratio, corrosion resistance, and high temperature stability. Titanium's low density—approximately 60% that of steel—combined with its ability to maintain strength at elevated temperatures makes it ideal for high-performance applications. These washers resist chemical attack, oxidation, and fatigue, ensuring reliable load distribution in even the most demanding environments.

Manufactured to the precise DIN 125A standard, these Titanium washers ensure compatibility across a wide range of fasteners and assemblies. The standard specifies that the outside diameter is typically twice the inside diameter, providing reliable performance and consistent load distribution in every application.

Titanium washers are prized for their high strength-to-weight ratio, making them stronger than mild steel while offering up to 40% weight savings. They maintain their strength at higher temperatures and resist corrosion, making them ideal for demanding environments such as aerospace, marine, and performance automotive applications.

Grade 2 Titanium (Commercially Pure Titanium, CP-Ti) is a soft, highly ductile Titanium alloy with excellent corrosion resistance. Its high formability makes it ideal for applications where shaping, bending, or welding is required. While it has a lower tensile strength compared to alloyed Titanium, it performs exceptionally well in environments exposed to chemicals, saltwater, or high humidity. Typical applications include chemical processing equipment, marine hardware, and lightweight structural components where flexibility is more important than maximum strength.

Grade 5 Titanium (Ti-6Al-4V), on the other hand, is an alloyed Titanium consisting of 6% Aluminium and 4% Vanadium. This combination significantly increases tensile strength (roughly twice that of pure titanium) while maintaining excellent corrosion resistance and a low density. Grade 5 Titanium is ideal for high-stress and high-performance applications, including aerospace, motorsport, medical implants, and other structural components where durability, weight savings, and resistance to fatigue are critical.

When selecting the right Titanium grade for washers or other fasteners, the choice comes down to strength vs ductility:

Understanding these differences ensures that your Titanium washers or components perform reliably under the intended mechanical and environmental conditions.

Titanium washers are valued for their lightweight, high strength, and corrosion resistance, making them suitable for a wide range of demanding applications. They are commonly used in:

If you need assistance selecting the right washer or would like to discuss custom options, contact our expert team at 01233 713581.