Value Added Services

At this stage our dedicated account managers will work with you to bring your concept or enquiry to life.

We employ regimented processes that can be adapted bespoke to your requirements which ensures success.

Our team are dedicated to meeting project deadlines with a 24 hour dispatch running Monday to Sunday.

Our technical engineering and vast product expertise guarantees a great customer experience every time.

At Vital Parts' we are proud to be supporting custom product development and manufacturing across the product lifecycle, we do this by offering a range of 'Value Added Services' that are geared towards optimising production efficiency and ensuring you get the best service possible.

Whether you are seeking technical advice at the early stages of product development or looking to decrease manufacturing costs, our aim is to Mould Around You with strong values and adaptable services to suit every application.

What Are The Benefits Of Our Value Added Services?

- Decrease manufacturing costs- We can help you save money on your manufacturing

processes by increasing efficiency, optimising material choices and analysing your product design to

ensure you are working as effectively as possible.

- Reduce supplier dependency - If you are reliant on one supplier due to design or

material availability, then we can help you by adjusting your design to reduce this dependency, by

suggesting alternative materials with similar or better performance or by suggesting a standard

alternative from our product range.

- Progressive prototyping - We're happy to work with you to achieve an optimal

product design that fits all criteria, working on progressive prototypes through product sampling to

ensure your satisfaction.

- External engineering support - Our in house team of engineering experts hold over 40

years of part production and product design experience, meaning you can rely on us for an external

source of knowledge, support and advice.

- Improved service - Our value offering is built around giving you the customer, the best service possible. We aim to achieve this by giving you a defined account manager at the enquiry stage, who's job it is to ensure you succeed in your objectives.

What Are The Value Added Services That You Offer?

We offer a number of value added services to suit varying business requirements, from managing the product lifecycle on your behalf to custom product design and manufacturing. Our in house team of experts are happy to be an extension of yours, to improve processes, products or production efficiencies.

Click through the tabs below to find out more!

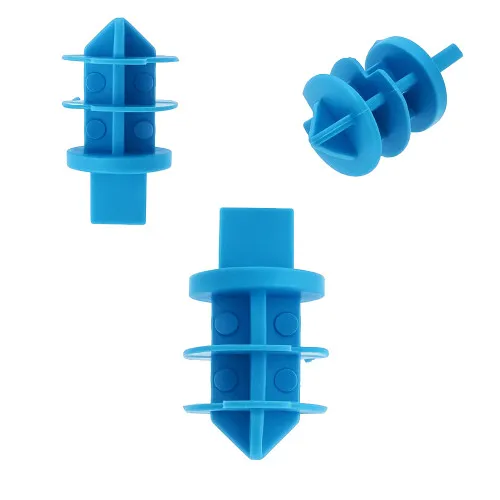

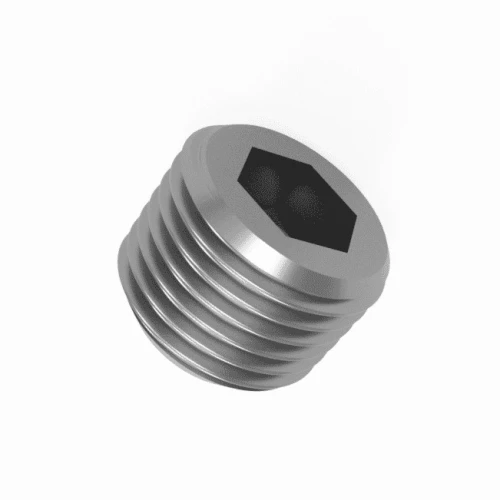

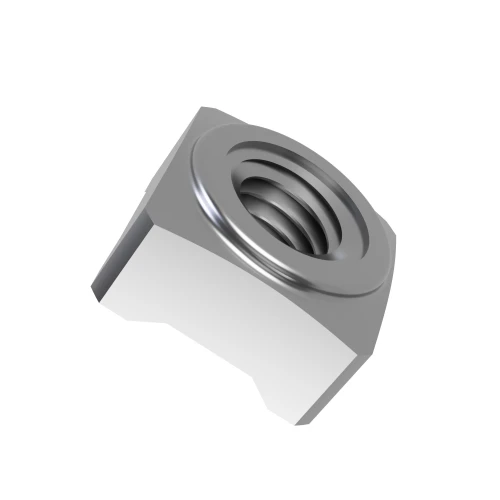

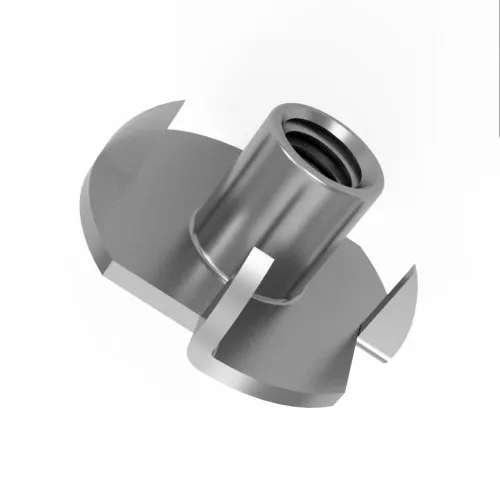

We are pleased to offer a range of comprehensive custom product manufacturing services, employing moulding techniques like injection moulding, dip moulding, overmoulding and extrusions just to name a few. We are able to nurture your project to success with in house engineers that can create 3D CAD files and a rapid prototype, to perfect the product first time.

Learn more about our range of manufacturing techniques, by visiting our Custom Moulding page.

How We Help With Custom Product Manufacturing

- Your own dedicated account managers who's job it is to nurture your project to success

- Free sampling through rapid prototyping of your initial design

- Vast range of industry-wide experience

Our Product Development And Custom Manufacturing Process

We have the ability to help you to manage the product lifecycle, simply treat us as an extension of your team. From assistance at the early development stage, to finding a solution to decrease your manufacturing or material costs we are happy to work with you on any project.

- Development

- CAD Design And Practical Mock Up

- 3D Printed Rapid Prototypes (Free Sampling Process Available)

- Assistance At The Tooling Stage

- Design Specification Support

- Growth

- Manufacturing Process Optimisation

- Call Off Orders And Buffer Stock Levels Available

- Maturity

- Product Cost Optimisation Support

- Material Sourcing Analysis

- Decline

- Enhanced Product Manufacturing

- Supporting Next Generation Product Development

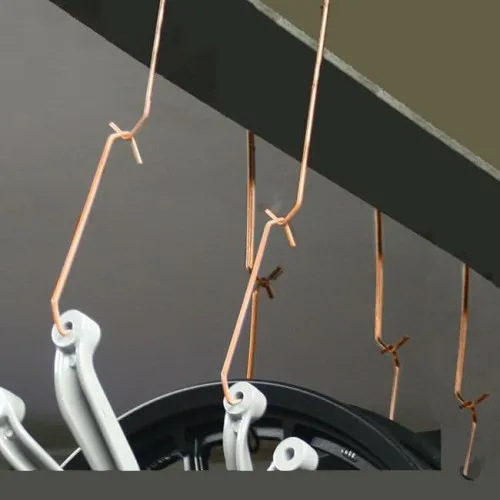

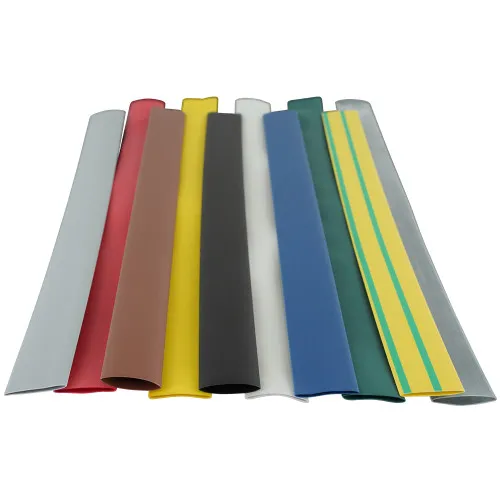

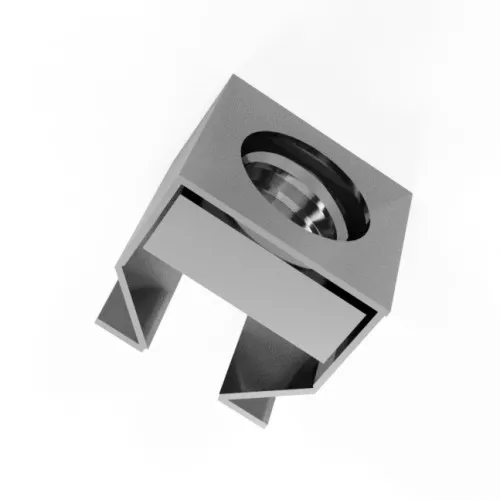

Our Second Line Finishing Services are offered for products that require a finishing touch before use, examples of which could include trimming, washing and hole punching. We are able to refine a product specific to your requirements, through secondary finishing services. Feel free to get in touch with your requirements and see exactly what we can do for you.

Past Examples Of Second Line Finishing Jobs:

- Drilling of Silicone Plugs to create a centre hole

- Washing of PVC to remove release agent

- Dying of products to requirements

- Trimming of excess material

- Laser cutting/finishing

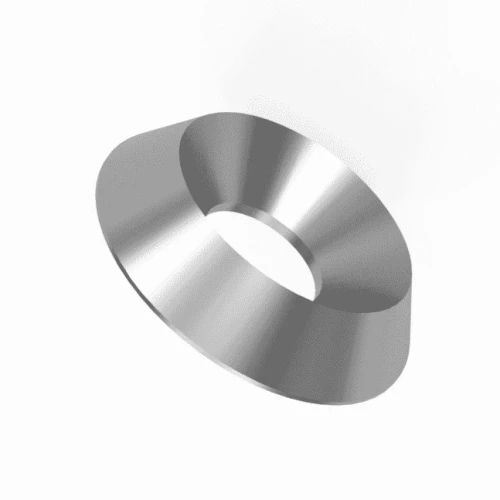

A huge part of the value we can add to your project, is the level of engineering and technical support that we are able to provide. We have a diverse team with a cumulative experience of over 60 years within technical and industrial industries, meaning we can assist with anything from tiny tweaks to a product design, to a full scale comprehensive re-design of your product. Call us at any time Monday to Friday and ask for our technical branch!