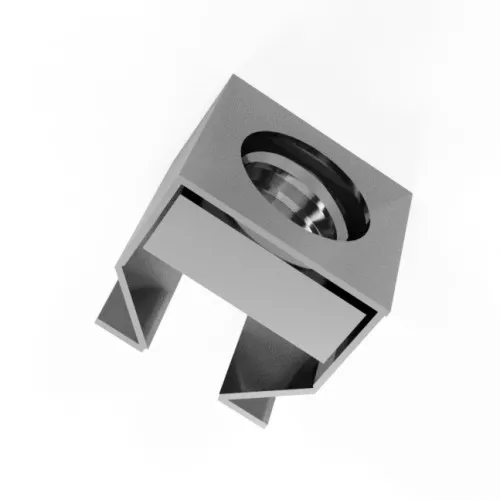

WHEN TO USE CHAIR FEET:

01

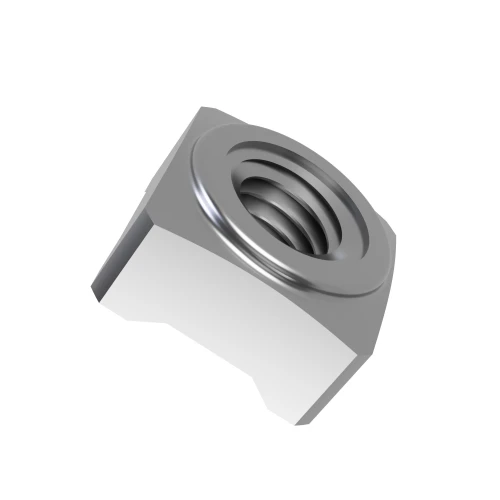

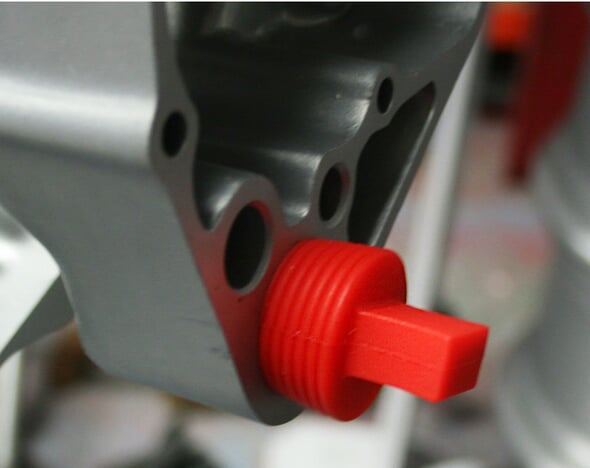

TO FINISH OR BLANK OFF A HOLE:

02

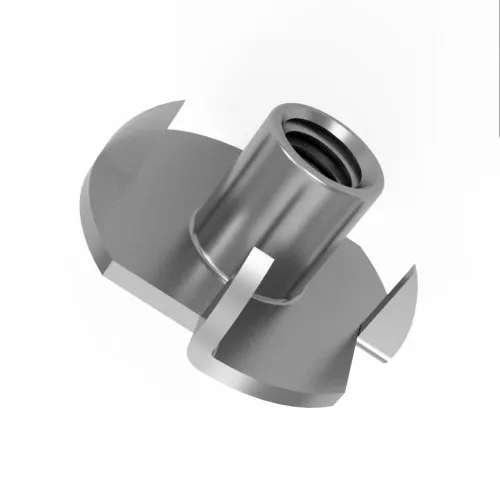

TO PROTECT A THREAD OR INTERNAL AREA:

03

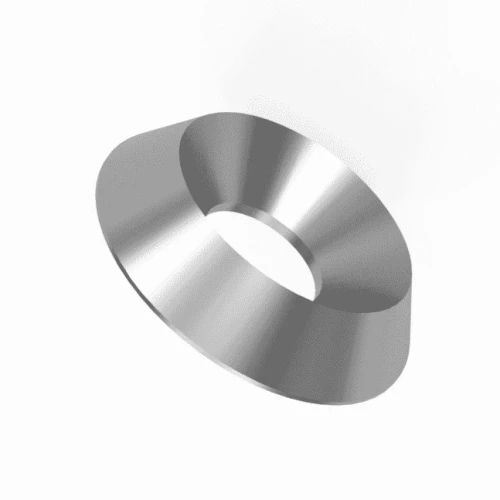

FOR MASKING USES DURING COATING OR PAINTING:

04

TO SEAL OFF AN AREA:

WHY USE PLUGS & STOPPERS

There are many reasons why you may choose to use Plugs, Bungs, or Stoppers over some of the other solutions that we offer. There is a large variety of sizes available to the type of finish or protection that is provided. But why use these over other solutions available to you?

EASE OF USE AND INSTALLATION:

VERSATILE SELECTION:

FREE SAMPLING ACROSS THE RANGE:

HOW TO MEASURE PLUGS & STOPPERS:

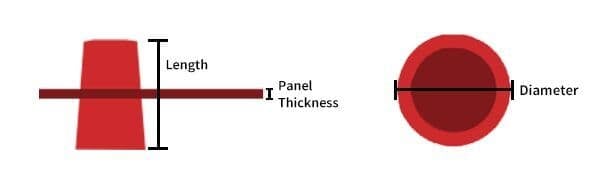

Measuring your hole for a proper fitting is essential to provide a hassle free experience. However, it is important to note that the ways of measuring differ depending on the application. For example, when fitting into a panel, you must take panel thickness into consideration. With standard holes, thickness isn't really an issue..

FOR PANELS

When measuring a plug for installation into a panel, it is important to note both the diameter required as well as the thickness of the panel that you're putting them into. As detailed in the diagram below, this is a fairly simple process. It requires using the measurements found to match up with solutions available on our site.

- Find Thickness of your panel

- Measure diameter of hole required

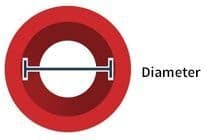

FOR STANDARD HOLES

Measuring up for standard holes is a quick and easy process in comparison to panel holes. The only consideration is the diameter and length required to fill the hole. Diameter is measured in the same way as pictured, making a note of your ideal length to match up with solutions available within our ranges.

WHAT'S AVAILABLE IN OUR PLUGS & STOPPERS RANGE?

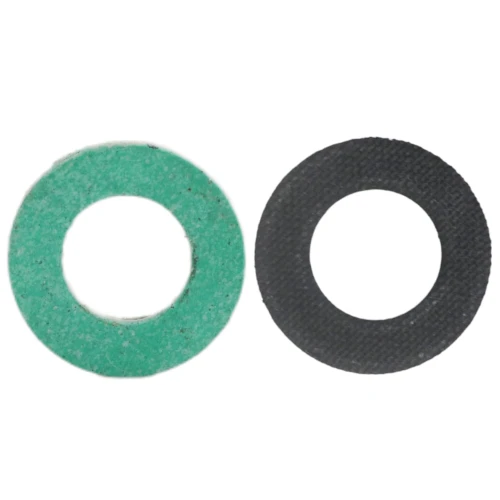

Our selection of Plugs, Bungs, and Stoppers covers a truly vast number of basic to specialist uses. These are within both industry and households. These products are split into two main types based on their material properties: Plastic & Rubber. It is important to have a good understanding of your needs and requirements before making a choice between them.

As a general rule, plastic is used to provide a clean or long term finish. Rubber is often used to seal off, or prevent access to, a particular area. Each solution can be used with a combination of panel holes, threaded holes and standard holes, where seen to meet the requirements of a project.

Below, we have split our selection of plugs into their plastic and rubber categories. Hopefully, this gives a better understanding of what we have on offer, as well as the uses available to you as a customer.

Plastic

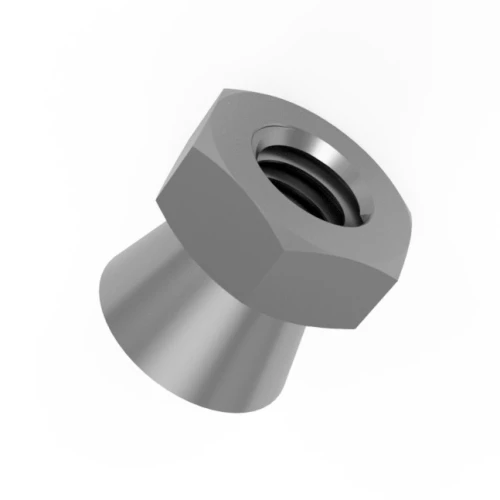

Plastic Plugs can be used to blank off, seal, protect, and finish off an application. We have a massively versatile selection of sizes and colours available for most involved uses.

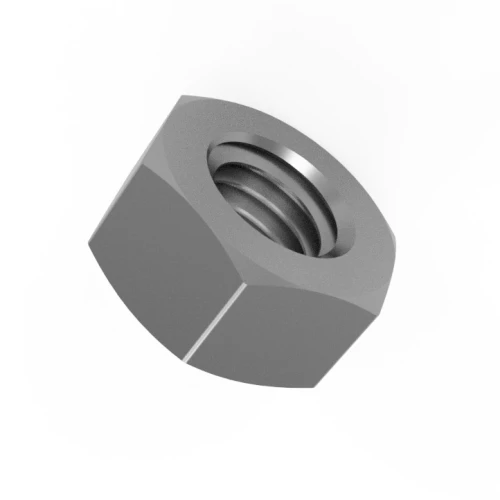

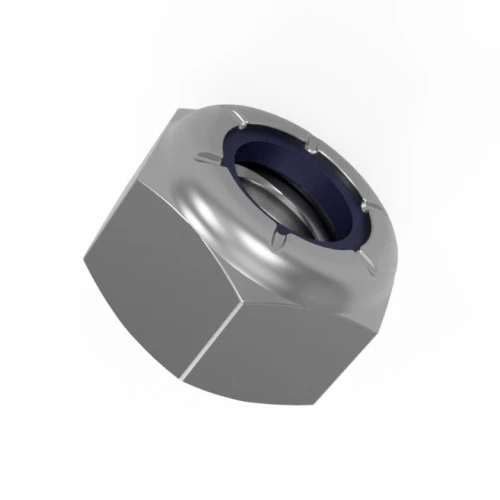

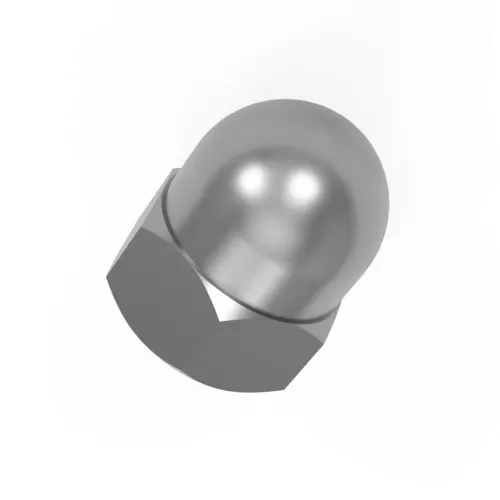

- Blanking Plugs: Domed, Vent, Body

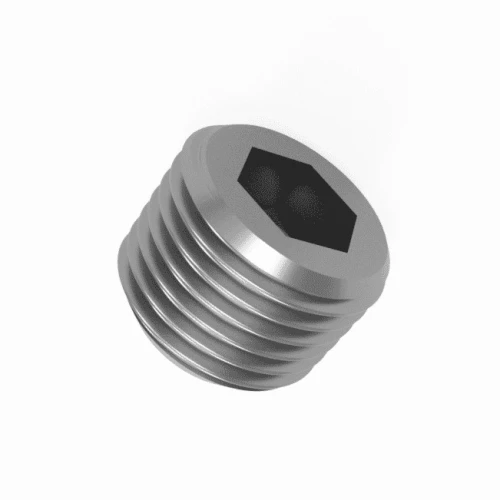

- Threaded Plugs: BSP & UNF

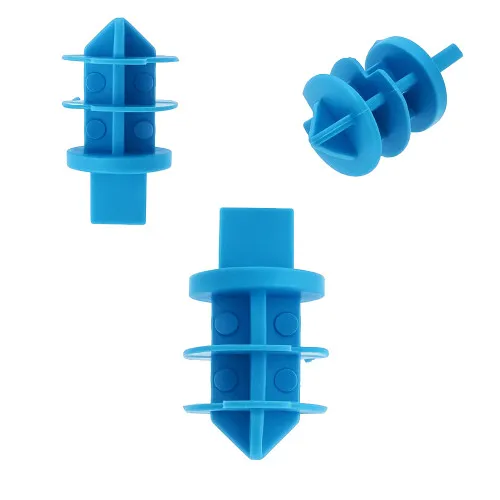

- Fir Tree Plugs

- Barrel Plugs

- Tapered Plugs

- Sealing Plugs

- Pipe Plugs

- Snap Fit Plugs

- Tube Plugs

Rubber

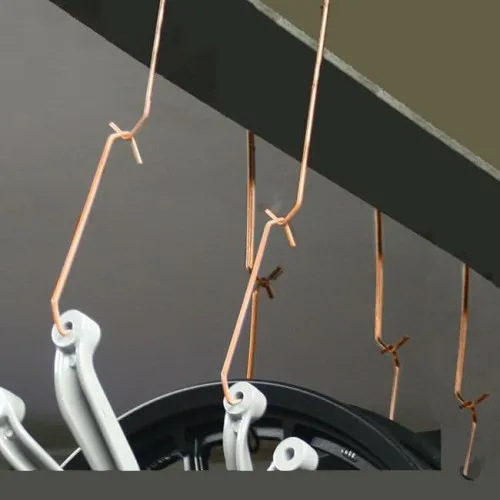

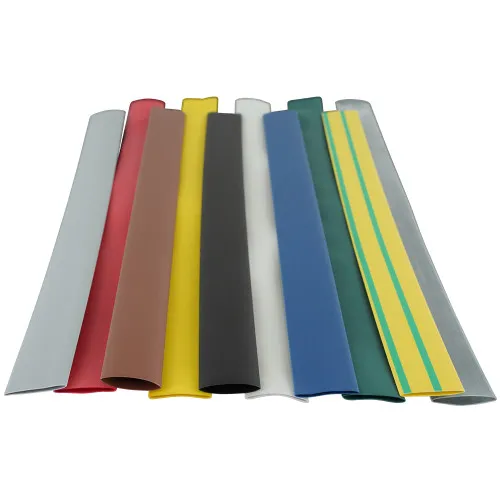

Rubber Plugs are often used to seal, protect, and mask off areas during painting or powder coating processes. In most cases, they offer high temperature resistance and an easy push fitting. This is along with excellent shock absorption properties.

- Silicone Plugs: Assorted Styles

- Tapered Bungs: EPDM & Silicone

- Rubber Blanking Plugs: Body & Flexible

- Masking Plugs

- EPDM Plugs

- Door Stoppers