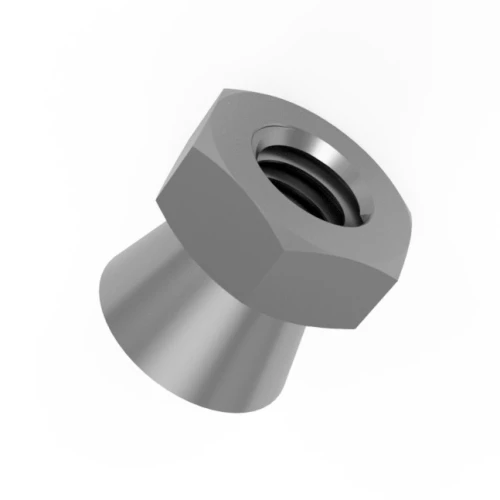

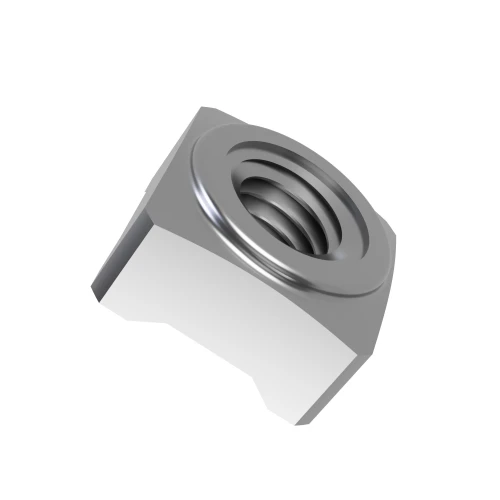

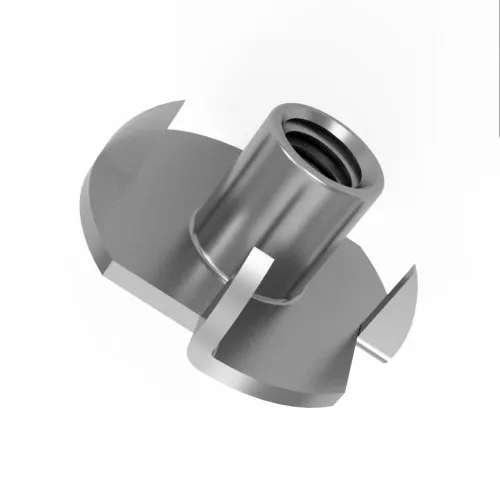

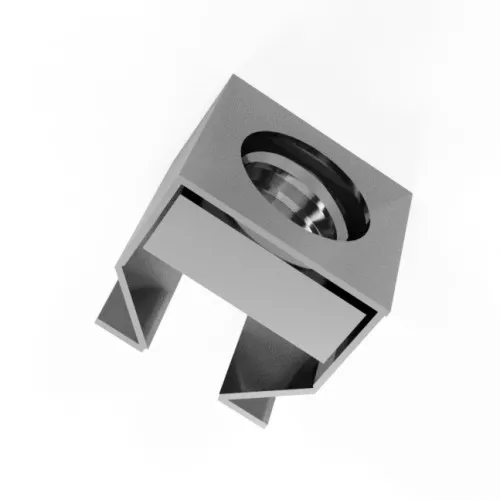

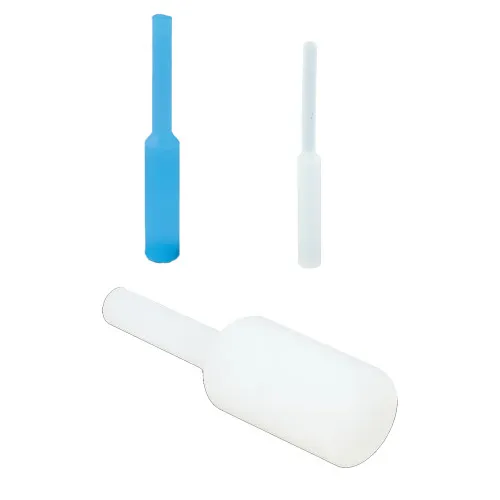

Silicone Cone Caps

Silicone cone caps are premium high-temperature masking solutions designed specifically for professional industrial applications across the UK. These cone-shaped protective covers are manufactured from premium-grade silicone rubber, enabling them to withstand extreme temperatures up to 315°C whilst maintaining their structural integrity and sealing properties. The unique tapered interior design allows these versatile masking caps to accommodate a range of diameters from a single product, making them ideal for masking threaded studs, rods, bolts, and tube ends during intensive finishing processes.

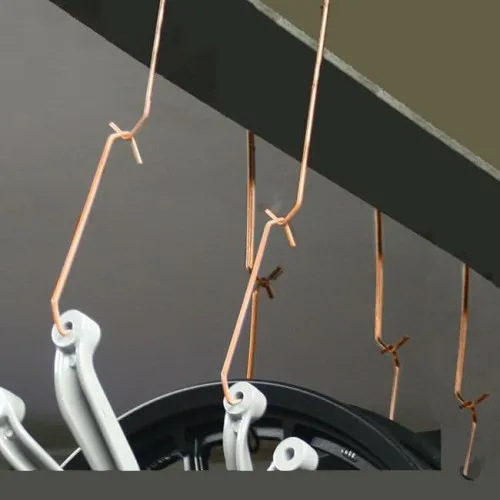

Widely used throughout the powder coating, shot blasting, and anodising industries across Britain, silicone cone caps provide exceptional protection against coating overspray, abrasive materials, and chemical exposure. Their primary benefit lies in their reusability and cost-effectiveness, as each cap can withstand multiple production cycles before replacement, significantly reducing operational costs whilst ensuring consistent, professional finishes on components ranging from automotive parts to architectural metalwork.

Available Materials and Style Options:

- Premium-grade silicone rubber construction for maximum durability

- Natural translucent finish as standard specification

- Custom colour options available for easy size identification and workflow organisation

- Tapered cone design with flexible interior to fit multiple diameter ranges

- Available in sizes from 3mm to 22mm to accommodate diverse industrial applications

- Custom sizing options available for specialised requirements

Key Features and Benefits:

- Exceptional temperature resistance up to 315°C, suitable for most industrial curing processes

- Tapered interior design provides secure fit across multiple diameters, reducing inventory requirements

- Outstanding chemical resistance to acids, alkalis, and industrial solvents commonly used in finishing processes

- Reusable design delivers significant cost savings compared to single-use alternatives

- Easy installation and removal, even when components remain hot after processing

- Flexible silicone construction prevents damage to delicate threads or surface finishes

- Superior sealing properties prevent coating penetration and contamination

- Excellent durability for extended use in demanding production environments

Common UK Use Cases:

- Powder coating masking in automotive component refurbishment, including alloy wheel restoration and chassis fabrication

- Shot blasting protection for engineering components in manufacturing facilities across the Midlands and Northern England

- Anodising masking for architectural aluminium products used in construction and building projects

- Electroplating applications in electronics manufacturing and precision engineering throughout the UK

- Industrial equipment maintenance and refurbishment in heavy industry sectors including oil and gas, marine, and aerospace

Related Vital Parts Products:

- Silicone Caps - Round silicone end caps for alternative masking requirements

- High Temperature Masking Plugs & Stoppers - Comprehensive range of silicone and EPDM plugs

- Silicone Washer Caps - Combined hole masking with surrounding surface protection

- High Temperature Masking Kits - Complete selection of caps, plugs, and tapes for various applications

For detailed guidance on selecting the correct masking solution for your specific application, visit our comprehensive Guide to High Temperature Masking, which covers measurement techniques, temperature considerations, and product selection criteria to ensure optimal results in your finishing processes.

Call Vital Parts:

For quick quotes, same-day dispatch, custom sizes, or bulk discounts, call our sales line on 01233 713581. Businesses can register for a Vital Parts Business Account to benefit from priority shipping, trade pricing, free product samples, credit accounts, and a dedicated account manager.

Categories

-

Plugs & Stoppers

-

Tapered Rubber Plugs

Tapered Rubber Plugs -

Blanking Plugs

Blanking Plugs -

Ventilation Plugs

Ventilation Plugs -

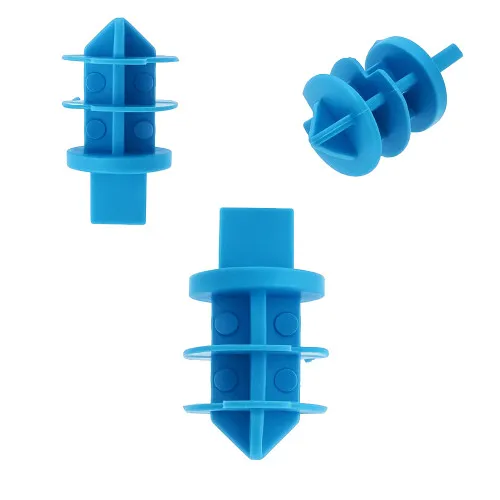

Fir Tree Plugs

Fir Tree Plugs -

Snap Fit Bushes

Snap Fit Bushes -

Liquid Tight Plugs

Liquid Tight Plugs -

Threaded Plugs

Threaded Plugs -

Threaded Sealing Plugs

Threaded Sealing Plugs -

Reversible Tapered Plugs

Reversible Tapered Plugs -

Washer Masking Plugs

Washer Masking Plugs -

Silicone Tapered Plugs

Silicone Tapered Plugs -

Silicone Ribbed Plugs

Silicone Ribbed Plugs -

Silicone Plugs With Handle

Silicone Plugs With Handle -

Silicone Step Plugs

Silicone Step Plugs -

Silicone Pull Plugs

Silicone Pull Plugs -

Silicone Thread Masking Plugs

Silicone Thread Masking Plugs -

Barrel Plugs

Barrel Plugs -

Cylindrical Pull Tab Plugs

Cylindrical Pull Tab Plugs -

Finned Pull Tab Plugs

Finned Pull Tab Plugs -

Round Tube Plugs

Round Tube Plugs -

Snap Fit Hole Plugs

Snap Fit Hole Plugs -

Ribbed Pipe End Plugs

Ribbed Pipe End Plugs -

Door Stoppers

Door Stoppers -

Finned Hole Plugs

Finned Hole Plugs -

Silicone Double Flange Plugs

Silicone Double Flange Plugs -

Silicone Flange Plugs

Silicone Flange Plugs -

Silicone Washer Plugs

Silicone Washer Plugs -

Plastic End Plugs

Plastic End Plugs -

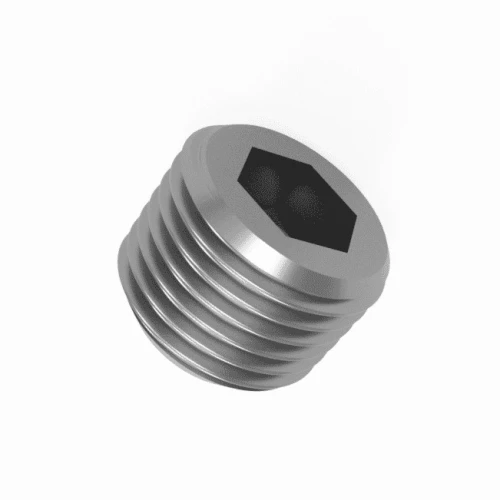

Stainless Steel Socket Pipe Plugs DIN 906

Stainless Steel Socket Pipe Plugs DIN 906

-

-

Furniture & Chair Feet

-

Adjustable Feet

-

Slotted Head Adjustable Feet

Slotted Head Adjustable Feet -

Rubber Adjustable Feet

Rubber Adjustable Feet -

Stainless Steel Adjustable Feet

Stainless Steel Adjustable Feet -

Ready To Install Sets

Ready To Install Sets -

One Piece Adjustable Feet

One Piece Adjustable Feet -

General Adjustable Feet

General Adjustable Feet -

Low Profile Adjustable Feet

Low Profile Adjustable Feet -

Machinery Mounting Feet

Machinery Mounting Feet -

Weight Rated Articulated Feet

Weight Rated Articulated Feet -

Heavy Duty Tilting Feet

Heavy Duty Tilting Feet -

Tilting Adjustable Feet

Tilting Adjustable Feet -

Metal Adjustable Feet

Metal Adjustable Feet -

Economic Adjustable Feet

Economic Adjustable Feet -

Allen Key Adjustable Feet

Allen Key Adjustable Feet -

Anti-Vibration Levelling Feet

Anti-Vibration Levelling Feet -

Balance Feet

Balance Feet -

Polyamide Adjustable Feet

Polyamide Adjustable Feet -

Pozi Base Adjustable Feet

Pozi Base Adjustable Feet -

Hexagon Base Feet

Hexagon Base Feet -

Threaded Fittings & Fixings

Threaded Fittings & Fixings

-

-

Cable Management

-

Cable Glands

Cable Glands -

Strain Relief

Strain Relief -

Rubber Grommets

Rubber Grommets -

Cable Ties

Cable Ties -

Blanking Plugs

Blanking Plugs -

Cable Clips

Cable Clips -

Cable Tie Mounts

Cable Tie Mounts -

Velcro Cable Management

Velcro Cable Management -

Aluminium Cable Clips

Aluminium Cable Clips -

Braided Cable Sleeving

Braided Cable Sleeving -

Multi Cable Clips

Multi Cable Clips -

PVC Cable Sleeving

PVC Cable Sleeving -

Spiral Cable Wrap

Spiral Cable Wrap -

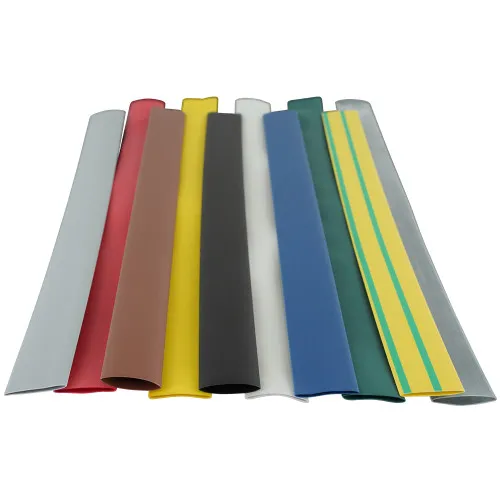

Heat Shrink Sleeves

Heat Shrink Sleeves -

Plastic Grommet Strips

Plastic Grommet Strips -

Adhesive Lined Heatshrink

Adhesive Lined Heatshrink -

Heat Shrink Caps

Heat Shrink Caps -

Nylon P Clips

Nylon P Clips -

Nylon P Clamps

Nylon P Clamps -

Rubber Grommet Strips

Rubber Grommet Strips -

Desk Cable Tidies

Desk Cable Tidies

-

-

Bolts and Screws

-

Hex Head Screws and Bolts

Hex Head Screws and Bolts -

Cap Screws

Cap Screws -

Countersunk Screws

Countersunk Screws -

Button Screws

Button Screws -

Pan Head Machine Screws

Pan Head Machine Screws -

Cheese Head Slotted Screws

Cheese Head Slotted Screws -

Security Fasteners

Security Fasteners -

Self Tapping Screws

Self Tapping Screws -

Wood Screws

Wood Screws -

Screws for Plastic

Screws for Plastic -

Knurled Fasteners

Knurled Fasteners -

Shoulder Bolts

Shoulder Bolts -

Grub Screws

Grub Screws -

Threaded Rod (All Thread)

Threaded Rod (All Thread) -

Weld Studs

Weld Studs -

Number Plate Screws

Number Plate Screws -

Nylon Screws & Bolts

Nylon Screws & Bolts -

Stainless Steel Bolts By Metric Thread Size

Stainless Steel Bolts By Metric Thread Size -

Small Bolts

Small Bolts -

Large Bolts

Large Bolts -

Industrial Hardware

Industrial Hardware

-

-

Washers

-

Stainless Steel Flat Washers

Stainless Steel Flat Washers -

Stainless Steel Spring Washers

Stainless Steel Spring Washers -

Stainless Steel Curved Washers

Stainless Steel Curved Washers -

Stainless Steel Serrated Washers

Stainless Steel Serrated Washers -

Stainless Steel Tab Washers

Stainless Steel Tab Washers -

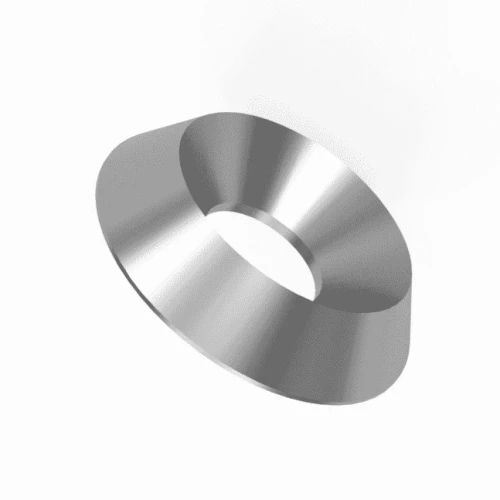

Stainless Steel Finishing Washers

Stainless Steel Finishing Washers -

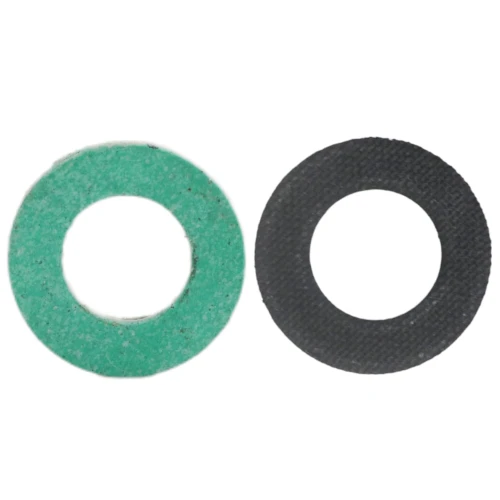

Bonded Sealing Washers

Bonded Sealing Washers -

Standard Nylon Washers

Standard Nylon Washers -

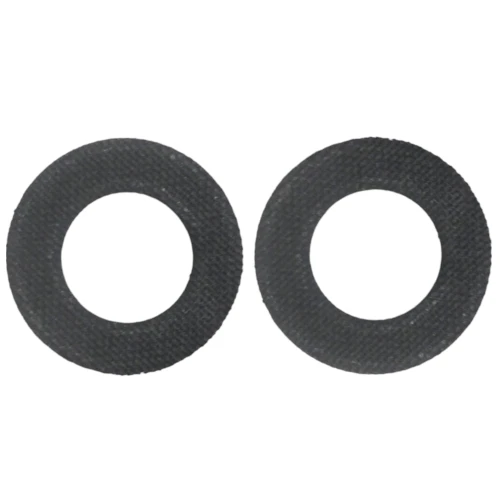

Rubber Washers

Rubber Washers -

Red Fibre Washers

Red Fibre Washers -

Peek Washers

Peek Washers -

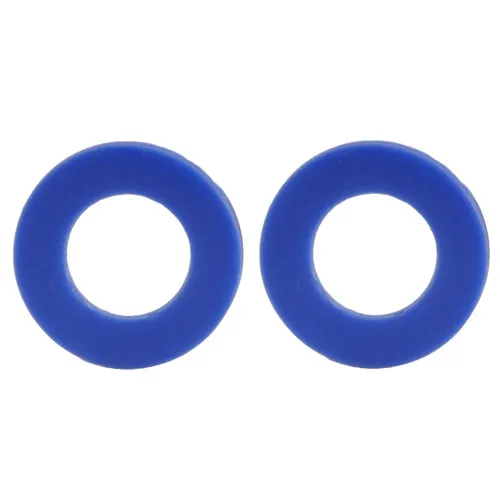

Silicone Washers

Silicone Washers -

PTFE Washers

PTFE Washers -

EPDM WRAS Washers

EPDM WRAS Washers -

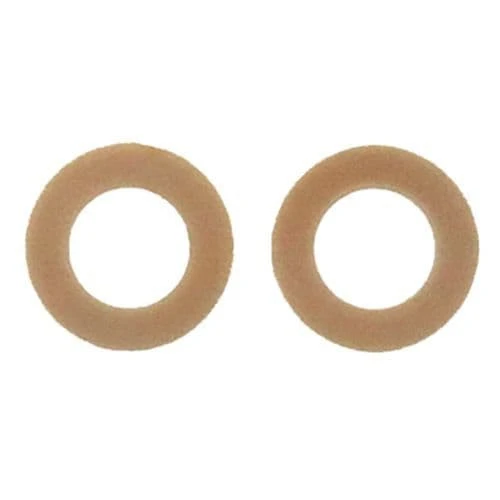

Fibre WRAS Washers

Fibre WRAS Washers -

FKM Washers

FKM Washers -

WRAS Washers

WRAS Washers -

Anti-Loss Washers

Anti-Loss Washers -

Finishing Washers

Finishing Washers -

Headboard Washers

Headboard Washers -

Saddle Washers

Saddle Washers

-

-

Industrial Hardware

-

Hinges

Hinges -

Camlocks

Camlocks -

Latches

Latches -

Detent Pins

Detent Pins -

Index Plungers

Index Plungers -

Clamping Handles

Clamping Handles -

Bridge Handles

Bridge Handles -

Pull Handles

Pull Handles -

Threaded Handwheels

Threaded Handwheels -

Wing Screws & Knobs

Wing Screws & Knobs -

Knurled Thumbscrews

Knurled Thumbscrews -

Ball Knobs

Ball Knobs -

Control Handwheels

Control Handwheels -

Door Bolts

Door Bolts -

Adjustable Feet

Adjustable Feet -

Furniture Fixings

Furniture Fixings -

Plastic & Rubber Grips

Plastic & Rubber Grips -

Roof Support Systems

Roof Support Systems -

Push Fit Knobs

Push Fit Knobs -

Edging Strips

Edging Strips

-

-

Adhesive Tapes

-

PTFE Tape

PTFE Tape -

Packing Tape

Packing Tape -

Fragile Tape

Fragile Tape -

Cloth Tape

Cloth Tape -

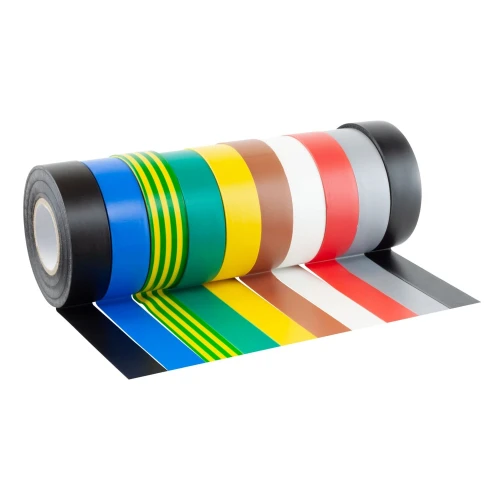

PVC Electrical Insulation Tape

PVC Electrical Insulation Tape -

Floor Marking Tape

Floor Marking Tape -

Safety Hazard Warning Tape

Safety Hazard Warning Tape -

Underground Cable Warning Tape

Underground Cable Warning Tape -

Non Slip Tape

Non Slip Tape -

Non-Adhesive Barrier Tape

Non-Adhesive Barrier Tape -

Double Sided Foam Tape

Double Sided Foam Tape -

UV Resistant Blue Masking Tape

UV Resistant Blue Masking Tape -

High Temp Crepe Tape

High Temp Crepe Tape -

Low Tack Paper Masking Tape

Low Tack Paper Masking Tape -

Aluminium Foil Tape

Aluminium Foil Tape -

Self Amalgamating PVC Tape

Self Amalgamating PVC Tape -

Self Amalgamating Silicone Tape

Self Amalgamating Silicone Tape -

Self Amalgamating EPR Tape

Self Amalgamating EPR Tape -

Fleece Tape

Fleece Tape -

Matte Cloth Tape

Matte Cloth Tape -

Glass Cloth Tape

Glass Cloth Tape -

Red Polyester Tape

Red Polyester Tape -

Anti Static Polyimide Tape

Anti Static Polyimide Tape -

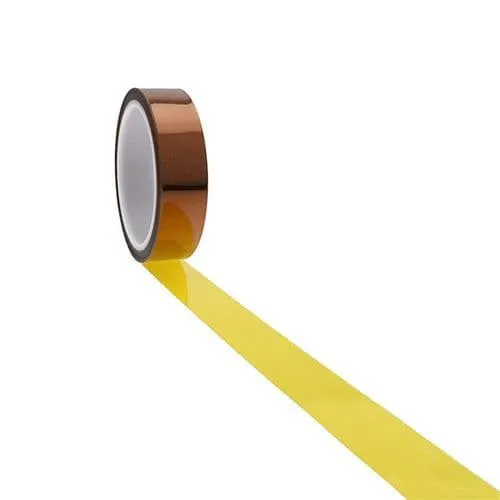

Amber Polyimide Tape

Amber Polyimide Tape -

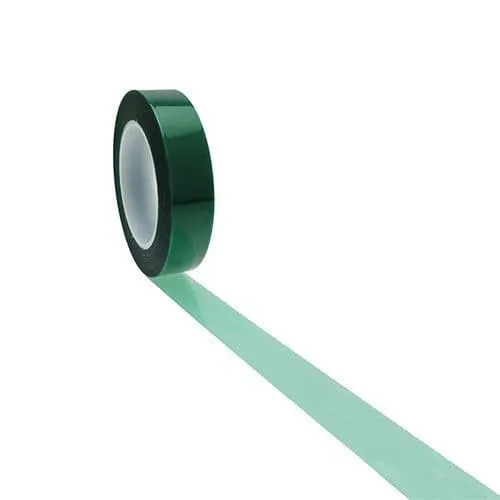

Green Polyester Tape

Green Polyester Tape -

Blue Polyester Tape

Blue Polyester Tape

-

-

Panel Fasteners

-

School & Office Products

-

Rubber Seals

-

Business Services

- Business Account

- Knowledge Hub

- Custom Moulding Services